Dedusting facility

A facility and hollow cavity technology, applied in the field of dust removal facilities, can solve the problems of insufficient mixing of water and solvent, the position of water spray cannot be adjusted according to actual needs, and the precise positioning of water spray cannot be achieved, so as to improve work efficiency. , Improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

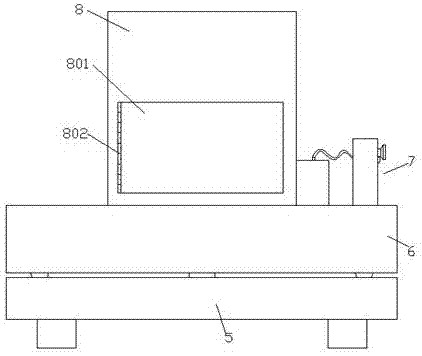

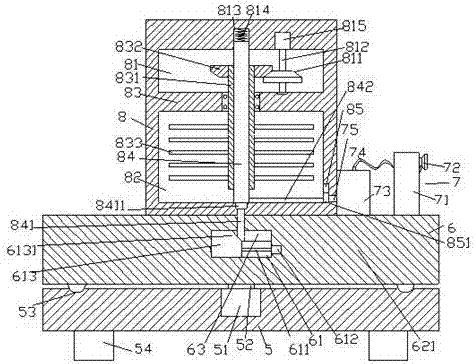

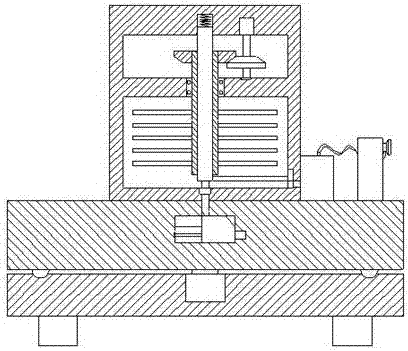

[0021] like Figure 1-Figure 4 As shown, a kind of dedusting facility of the present invention comprises a base 5 and a base frame 6 arranged on the top of the base 5 and is screwed and connected, and the top of the base frame 6 is fixedly provided with a spray box 8, and the spray box 8 The top of the base frame 6 on the right side is provided with a spray device 7, and the base frame 6 below the spray box 8 is provided with a hollow cavity 63, and the inner bottom of the hollow cavity 63 is provided with a guide groove 61, The guide groove 61 is provided with a first helical rod 611 extending left and right, and a guide block 613 is connected to the helical thread on the first helical rod 611, and the top of the guide block 613 is provided with an extension. To the oblique end pushing block 6131 in the hollow cavity 63, the spray box 8 is provided with a first hollow cavity 81 and a second hollow cavity 82, and the first hollow cavity 81 and the second hollow cavity 82 A pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com