Limiting device used for cut-off deflection rectifying of prefabricated square pile

A technology of limiting device and prefabrication, which is applied in the field of building deviation correction, can solve problems such as easy occurrence of deviation, and achieve the effect of preventing translation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

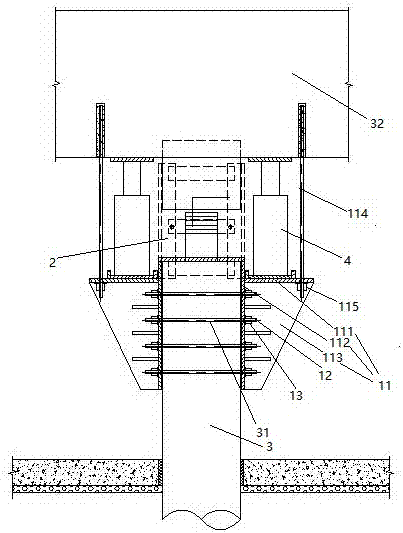

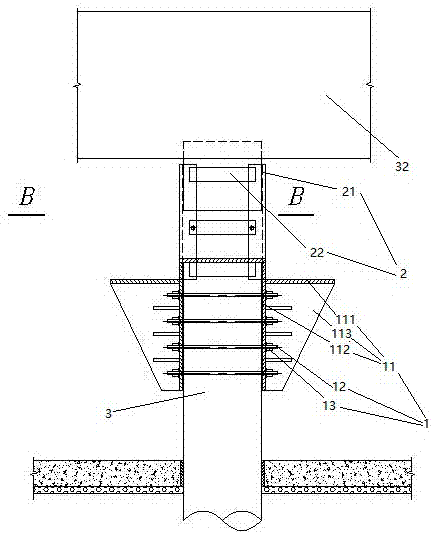

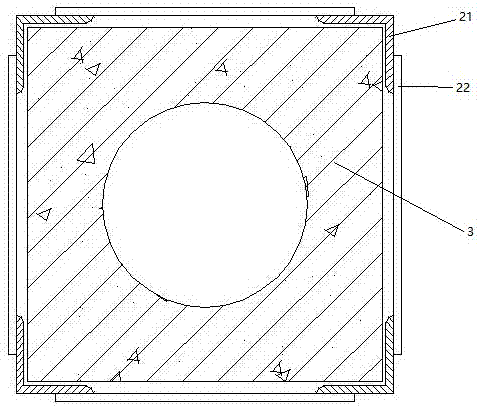

[0020] Embodiment one, see figure 1 , a position-limiting device for truncation and rectification of prefabricated square piles, comprising a support base 1 and a quadrangular prism-shaped position-limiting sleeve 2 . The support base 1 includes two support plates 11 and several bolts 12 . The support board 11 includes a horizontal support board 111 , a vertical support board 112 and a reinforcement board 113 . The horizontal support plate 111 and the vertical support plate 112 are vertically connected together. The reinforcing plate 113 is a right triangle. One right-angled side of the reinforcing plate 113 is connected with the horizontal support plate by welding, and the other right-angled side is connected with the vertical support plate by welding. The two ends of the bolt 12 pass through the vertical support plates of the two support plates one by one and are screwed together with the fixing nut 13 so that the support plates are clamped and fixed on the square piles. ...

Embodiment 2

[0025] Embodiment two, the difference with embodiment one is:

[0026] see Figure 4 , also includes a limit sleeve connection structure 5. Connect the quadrangular prism-shaped spacer sleeve with the support base 1 through the spacer sleeve connection structure 5 with the support base 1 (only the support plate 41 is shown in the support base). Specifically: the limit sleeve connection structure 5 includes a circular sliding rail 51, a circular sliding groove 52 that is rotatably connected on the circular sliding rail, a vertical connecting rod 53 whose lower end is connected together with the circular sliding groove, connected to the support The circular upper slide groove 54 on the bar upper end, the circular upper slide rail 55 that is rotatably connected on the circular upper slide groove and the horizontal connecting rod 56 that one end is connected on the circular upper slide rail. The circular lower rail 51 is fixedly connected with the support base 1 , specifically w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com