Intelligent clamping force adjusting oil cylinder

A technology of intelligent adjustment and clamping force, applied in the direction of fluid pressure actuation device, etc., can solve the problems of difficult quality assurance, high manufacturing cost and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

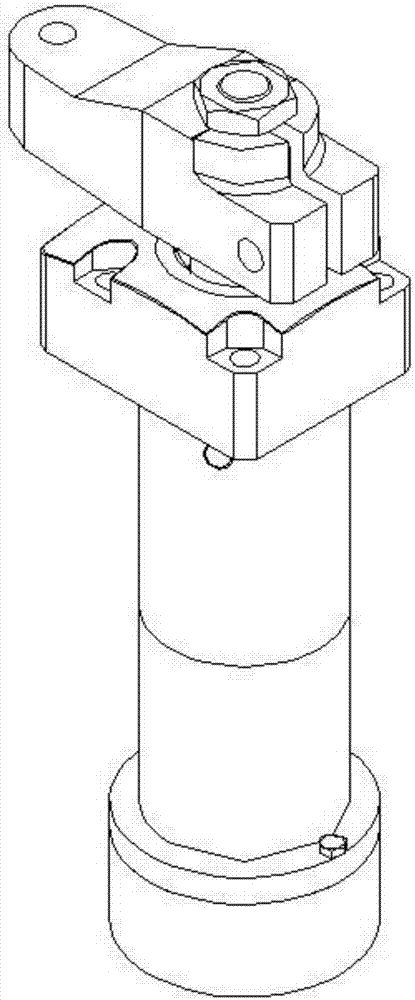

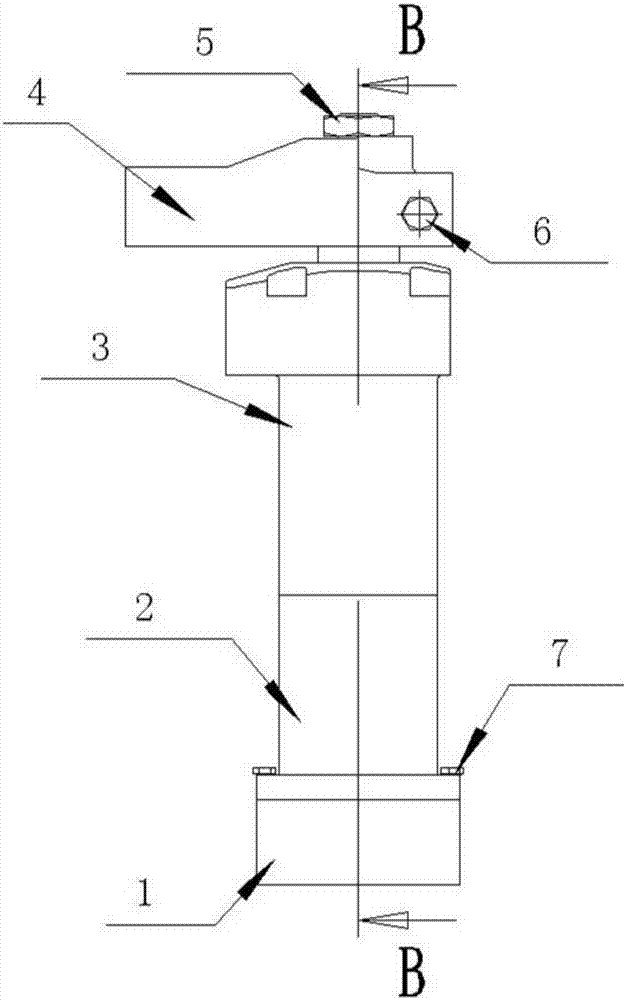

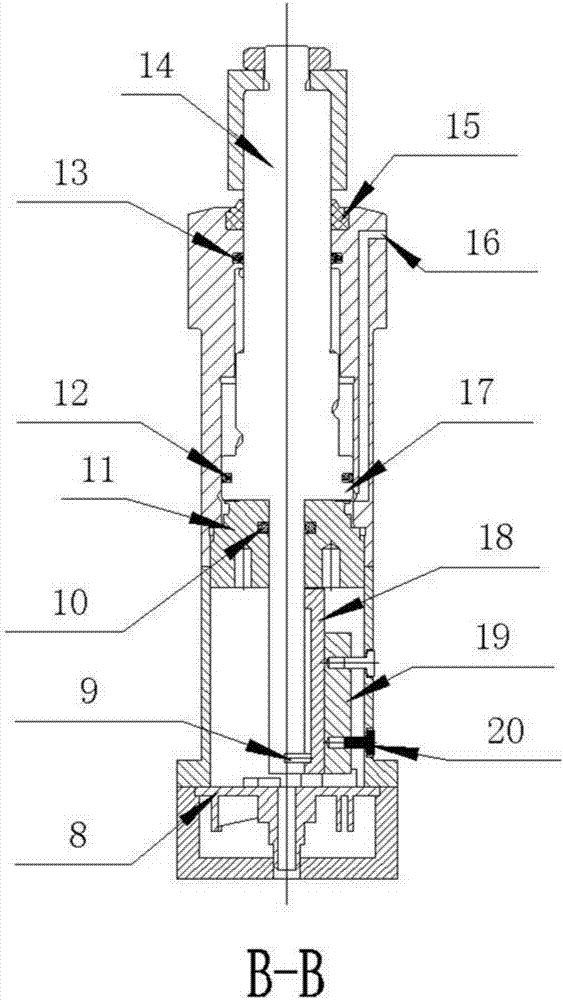

[0020] Such as Figure 1-Figure 6 As shown, the intelligent adjustment clamping force cylinder includes base 1, lower pump body 2, upper pump body 3, compression rod 4, signal amplification circuit board 8, sensor head 9, oil plug 11, piston, oil inlet 16, Sensor contact plate 18 and oil outlet 21; signal amplification circuit board 8 is installed in base 1, lower pump body 2 is installed on base 1 through connecting bolt 7, and upper pump body 3 is installed on lower pump body 2; The inner cavity between the pump body 2 and the upper pump body 3 is divided into an upper chamber and a lower chamber by an oil plug 11, and the oil plug 11 is fixed on the inner wall of the upper pump body 3; Rod 14, piston head 17 and piston lower rod; piston upper rod 14 and piston head 17 are located in the upper chamber, and the top of the piston upper rod 14 stretches out of the upper pump body 3, and the piston upper rod 14 and the upper pump body 3 pass through The sealing ring 13 is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com