High-power portable intelligent recharge and discharge machine

A charging and discharging machine, portable technology, applied in the field of high-power portable intelligent charging and discharging machine, can solve the problems of reducing battery capacity, difficult to control temperature, long charging time, etc., to achieve volume and weight reduction, ensure normal use, and shorten charging. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

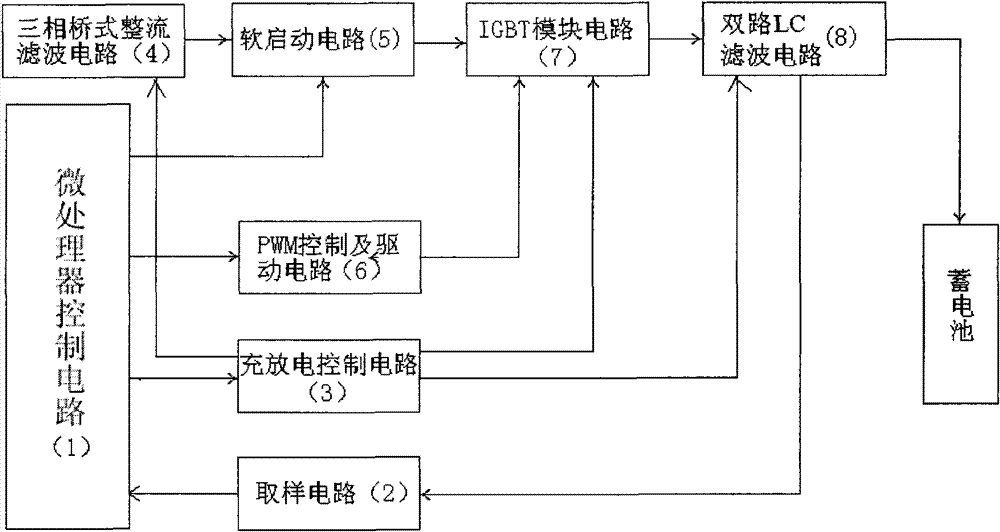

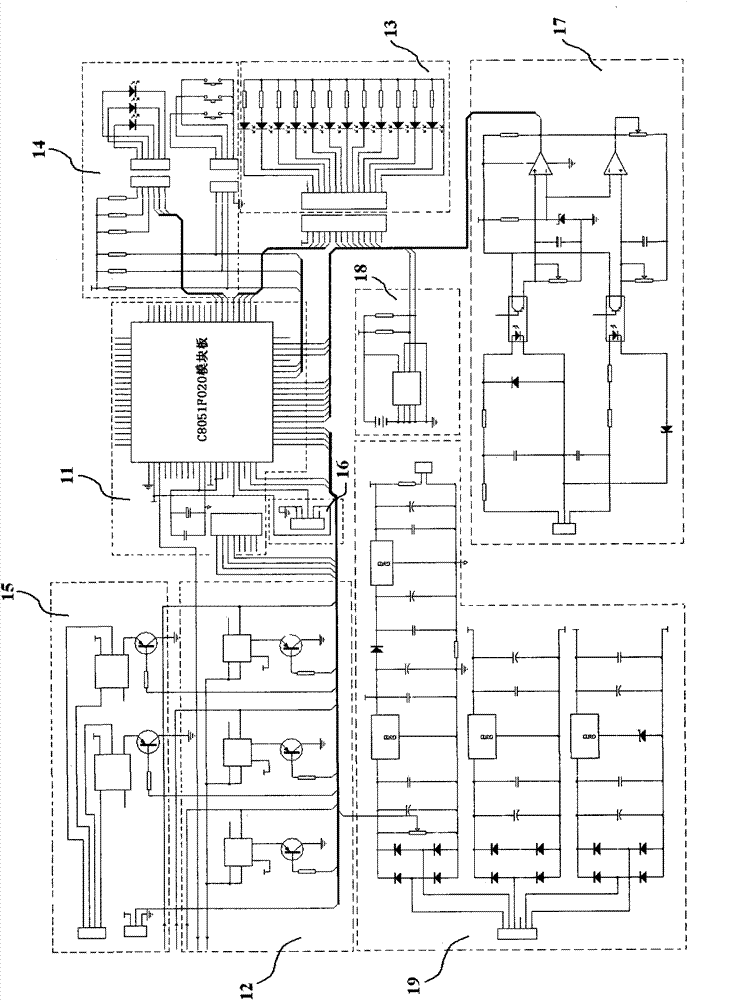

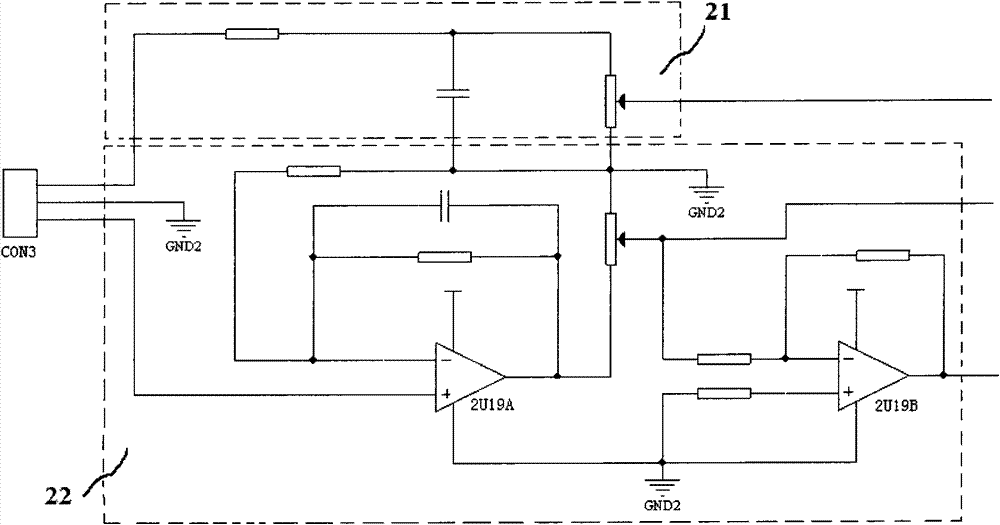

[0026] See figure 1 , Including a chassis, an electrical main loop installed in the chassis, the electrical main loop including a microprocessor control circuit 1, a sampling circuit connected to the detection shunt FL in the dual LC filter circuit 8, and the micro The charge and discharge control circuit 3, the three-phase bridge rectifier filter circuit 4, the soft start circuit 5, the PWM control and drive circuit 6, the IGBT module circuit 7, and the dual LC filter circuit 8 connected to the processor control circuit 1. The sampling circuit 2 sends the detected analog voltage and current signals to the microprocessor control circuit 1; the microprocessor control circuit 1 determines the condition of the battery according to the parameters detected by the sampling circuit 2; the three-phase bridge rectifier filter circuit 4 sends three Phase alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com