A fault classification and diagnosis method for high-speed train brake pipe based on pressure data

A technology of pressure data and diagnostic methods, which is applied in the direction of railway vehicle testing, mechanical component testing, machine/structural component testing, etc. It can solve the problems of time-consuming and low accuracy of brake pipe fault analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

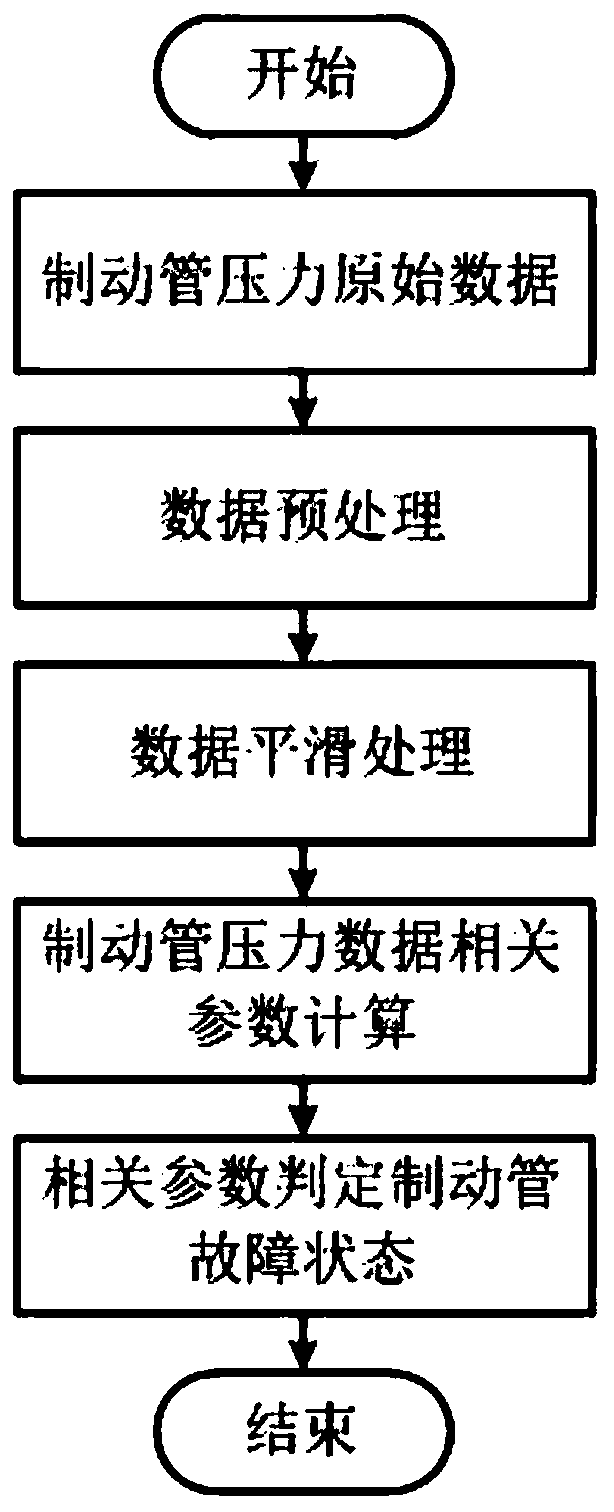

[0149] A method for classification and diagnosis of high-speed train brake pipe faults based on pressure data in the present invention, the flow chart is as follows figure 1 As shown, the specific steps are as follows:

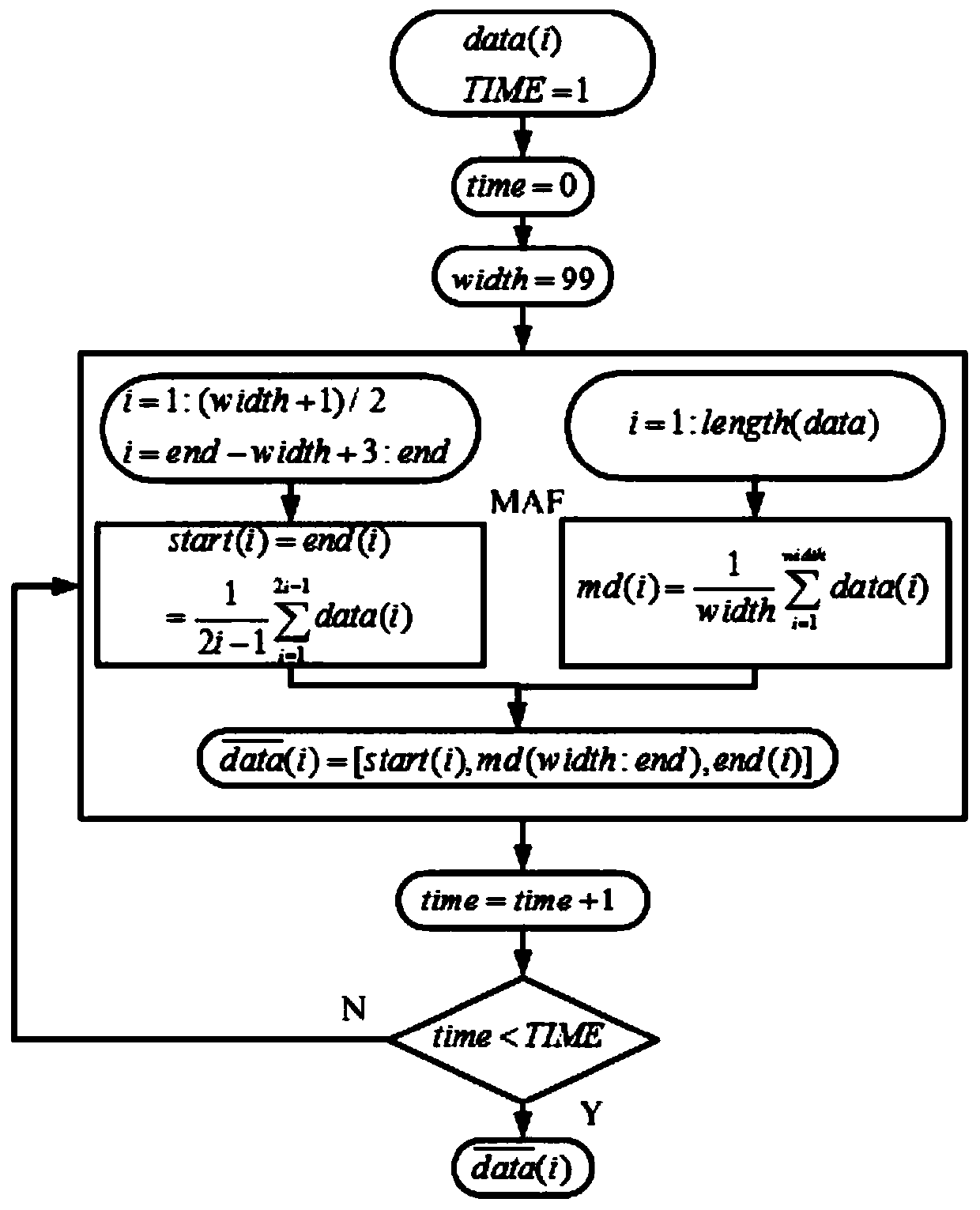

[0150] Step 1 is specifically implemented according to the following steps:

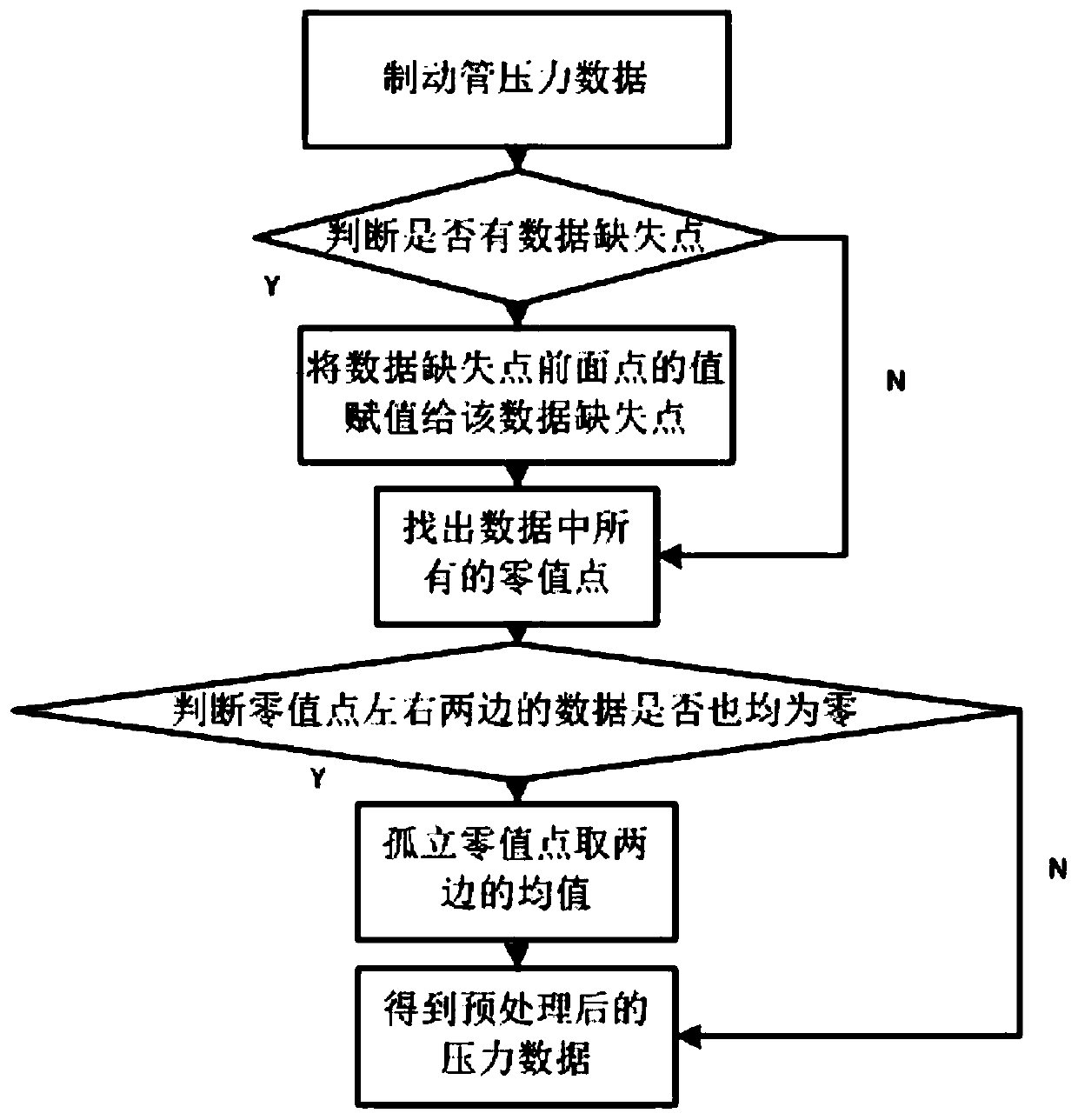

[0151] Step (1.1), supplement of data missing points:

[0152] Collect brake pipe pressure p(i), where i is the corresponding sampling time point, i=23, as shown in Table 1 and Table 2, draw a schematic diagram of the initial brake pipe pressure signal curve,

[0153] Table 1: Sampling data of brake pipe pressure p(i)

[0154] sampling time point 1 2 3 4 5 6 7 8 brake pipe pressure 9 8.6 8.4 8.7 9.4 9.8 0 sampling time point 9 10 11 12 13 14 15 16 brake pipe pressure 10.1 9.8 9.5 9 8.7 8.5 8.4 8.8 sampling time point 17 18 19 20 21 22 23 brake pipe pressure 9 9.4 9.8 10.1 9.6 9 9.3

[0155] Sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com