Harvesting machinery cleaning system fan control method, controller and control system

A harvesting machine and control method technology, which is applied to the control, controller and control system of the fan of the cleaning system when the harvesting machine is operating on the slope, and the control field of the fan of the harvesting machine's cleaning system, which can solve the problem of poor cleaning effect and manipulation. High intensity, short working time without failure, etc., to achieve the effect of simple manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

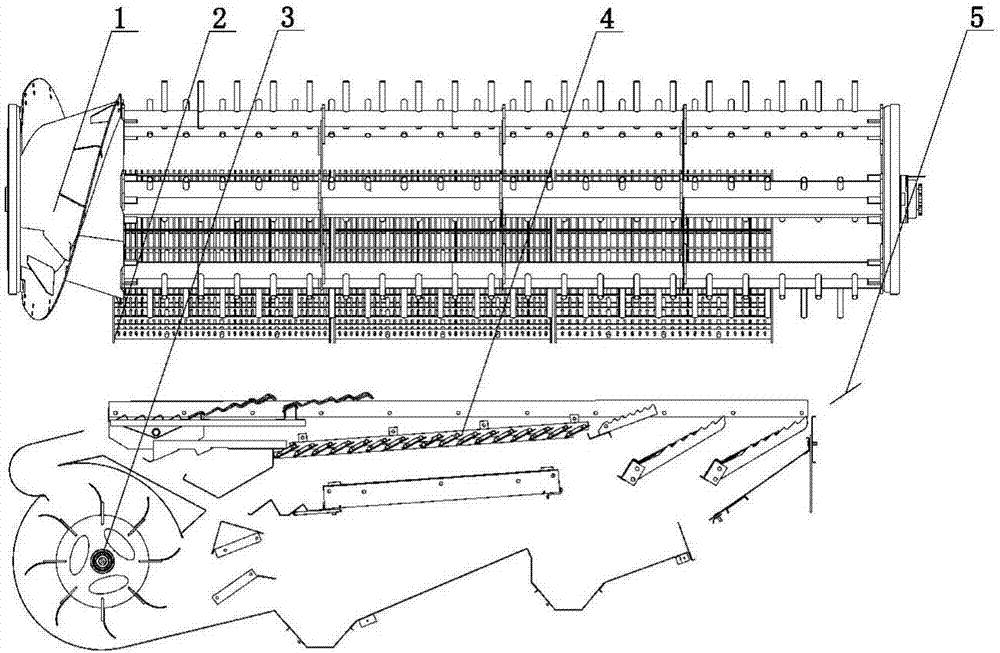

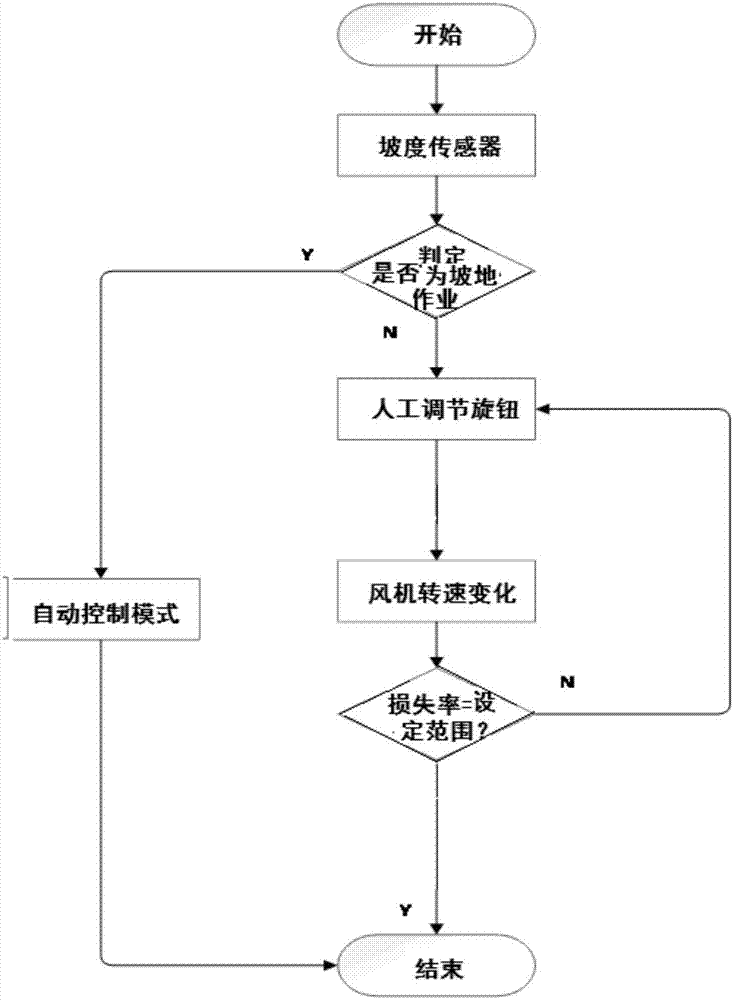

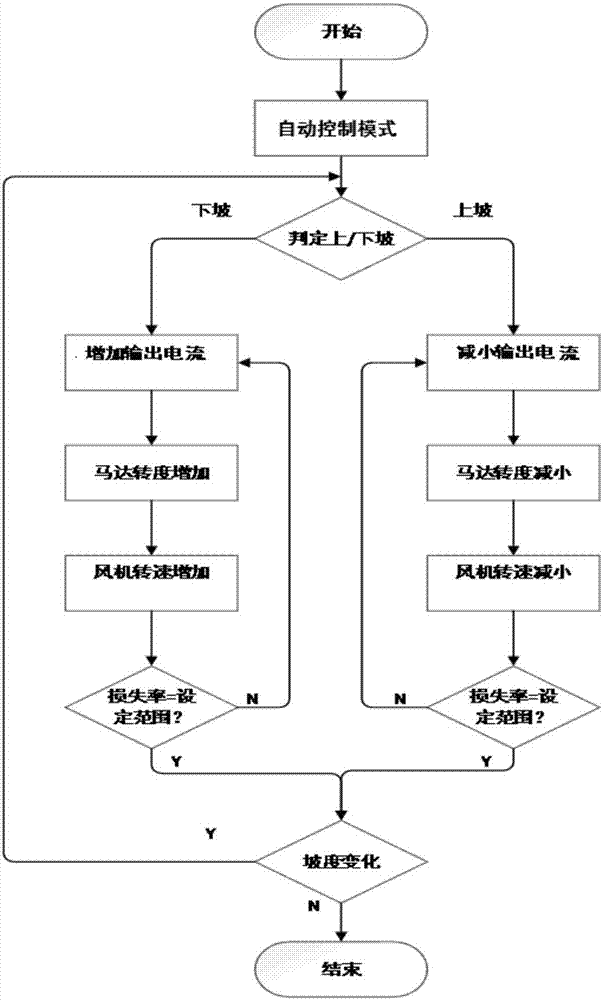

[0030] figure 1 is a flow chart of the control mode according to the control method of the present invention; figure 2 It is a flow chart of the automatic control mode according to the control method of the present invention when working on a slope; Figure 3A is a schematic structural diagram of the cleaning system; Figure 3B It is a schematic structural diagram of the fan assembly of the cleaning system; Figure 4 It is the operation diagram of the cleaning system when the vehicle is operating on a flat road; Figure 5 It is a schematic diagram of the cleaning system when the vehicle is working downhill. Image 6 It is a schematic diagram of the cleaning system when the vehicle is workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com