Feeding device used for packaging bar end portion slope shearing machine

A technology of feeding device and packaging strip, applied in the direction of metal processing, etc., can solve the problems of large cutting workload, deviation of the inclined surface processing angle of packaging strip, inability to precisely control the cutting length, etc. The effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

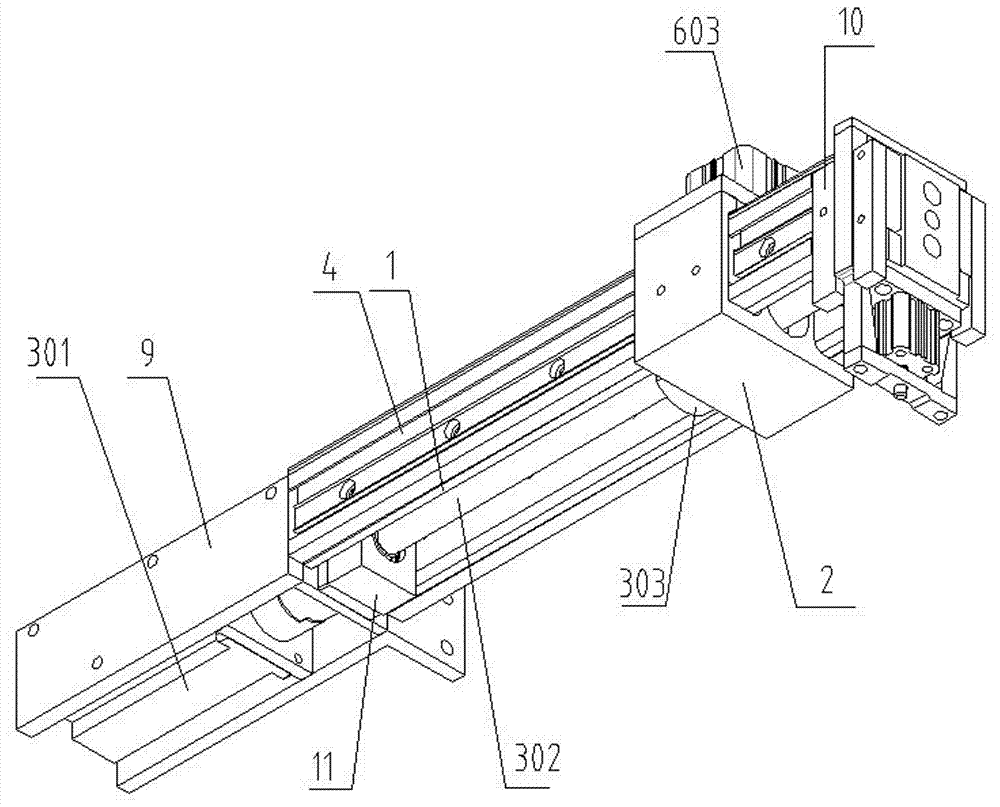

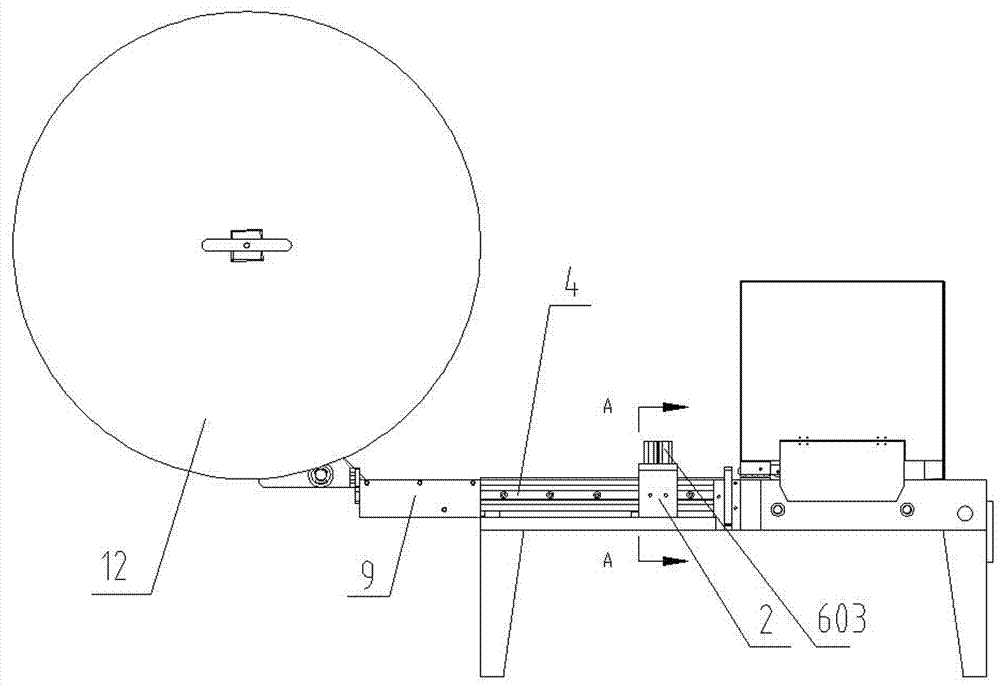

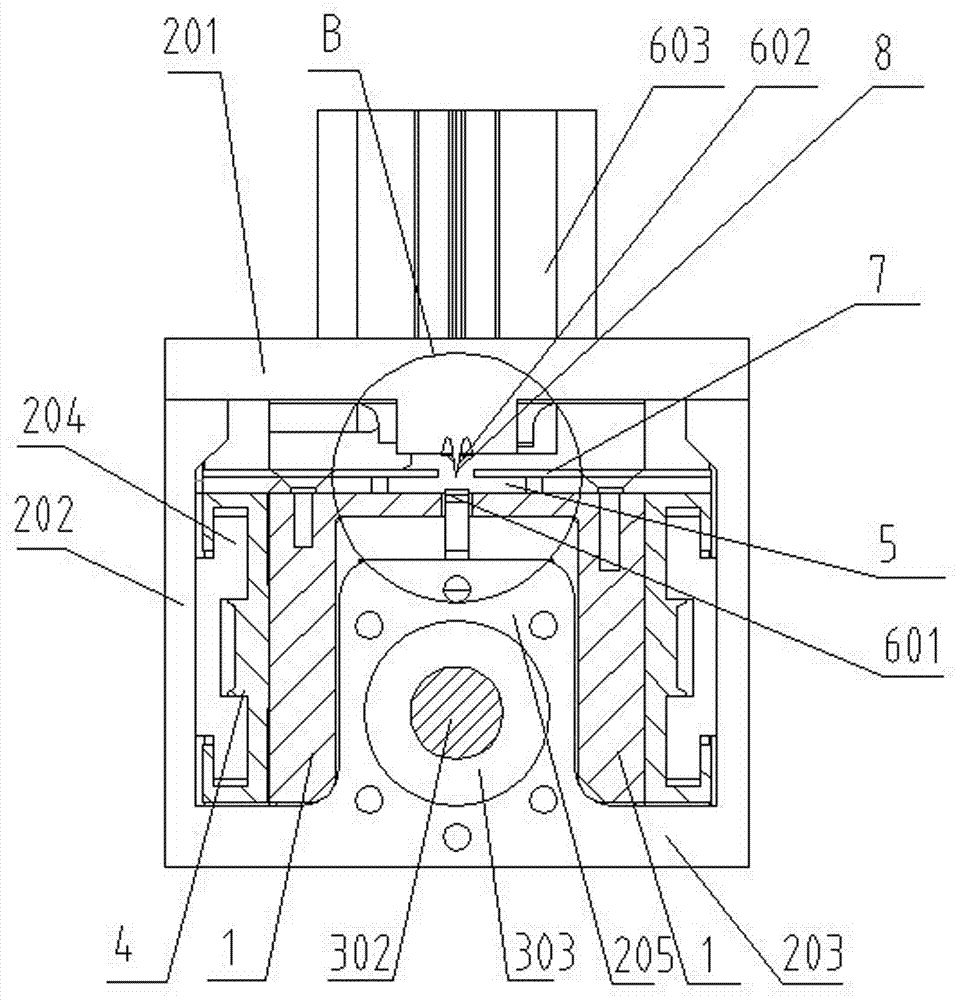

[0024] Such as Figure 1 to Figure 5 As shown, a feeding device of the present invention for a bevel shearer at the end of packaging strips includes a motor 301 arranged in the motor seat 9, a ball screw 302 connected to the output shaft of the motor 301, and a The bar 302 is axially arranged on the bracket 1 on the motor base 9 . A turntable 12 for coiling the packing bar is provided on the motor base 9 , and a lead screw nut 303 is fitted on the ball screw 302 . One end of the support 1 away from the motor 301 is connected to the cutter position of the packing strip cutter. The support 1 is provided with a feeding trough 5 corresponding to the cross-section of the packing bar along its length direction, and a feeding mobile frame 2 fixedly connected with a lead screw nut 303 is also slidably provided on the support 1. The clamping mechanism 6 for clamping the packing strips in the feeding chute 5 . In order to ensure the accuracy of the movement of the mobile feed frame 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com