Mildew-proof soaking device for sofa wooden board

A wood-panel and mildew-proof technology, applied in the sofa field, can solve the problems of no treatment, low production efficiency and high labor intensity, and achieve the effects of low cost, simple structure and good anti-corrosion and mildew-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

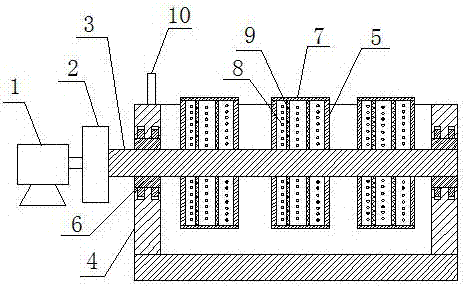

[0012] Such as figure 1 A kind of anti-mildew soaking device for sofa wood boards as shown, including motor 1, reducer 2, rotating shaft 3, solution placement tank 4 and wood board placement tank 5, the solution placement tank 4 has a hole, and a bearing 6 is arranged in the hole, and the rotating shaft 3 Pass through the bearing 6 and connect to the reducer 2 located outside the solution storage tank, the reducer 2 is connected to the motor 1, and a plurality of wooden board storage tanks 5 are evenly and symmetrically installed on the rotating shaft 3 in the solution storage tank 4 along its axial direction , the bottom of the plank placing groove 5 is open, the bottom plate of the groove 7 is hinged on the side wall of the bottom of the plank placing groove 5, and a plurality of water inlet holes 8 are arranged on the side wall of the plank placing groove 5; the plank placing groove 5 is welded on the rotating shaft 1; A plurality of partitions 9 are arranged in the placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com