Mother-son crucible device for evaporation composite metal coating

A composite metal film and crucible technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of uneven film layer, different evaporation range and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

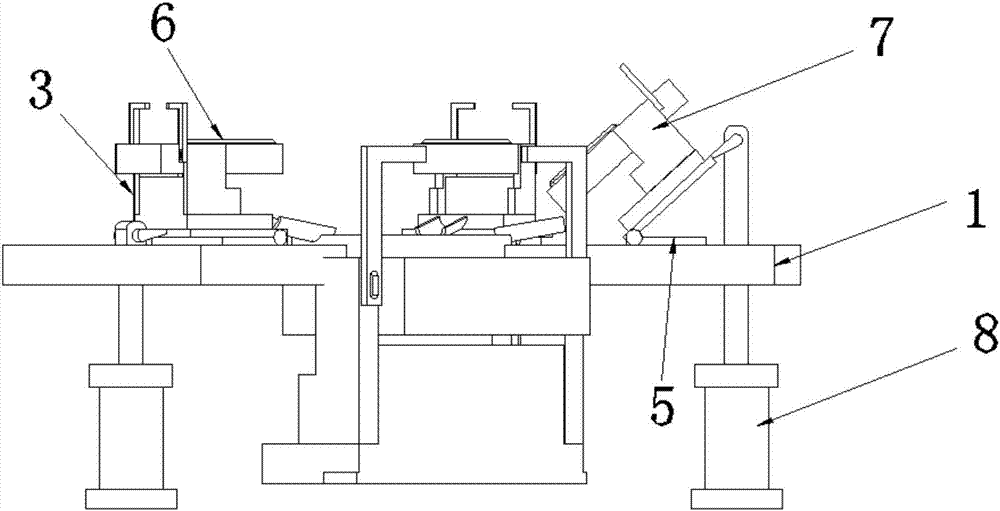

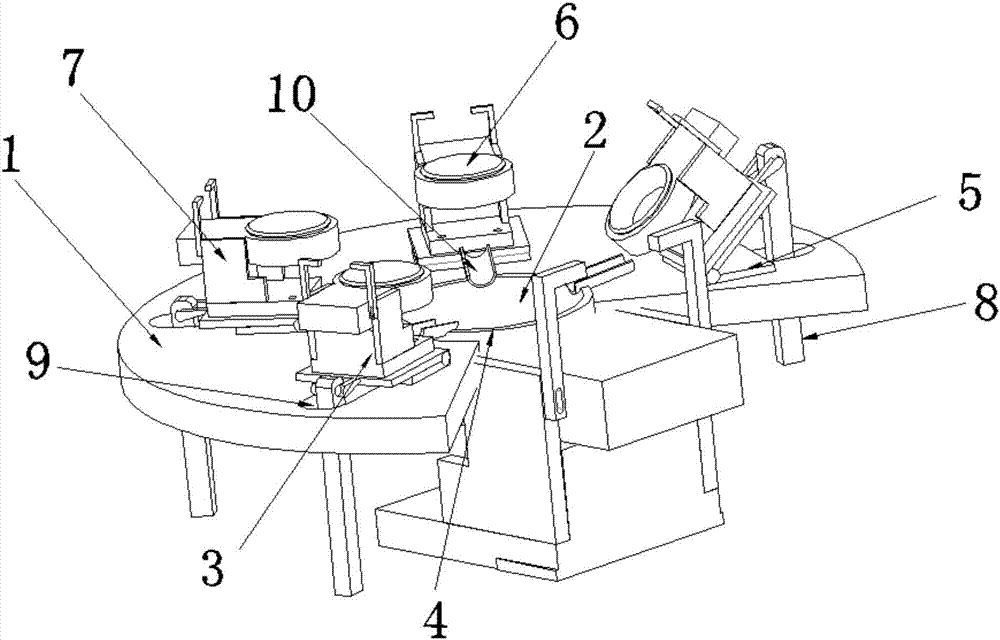

[0016] Such as Figure 1-2 As shown, a mother-child crucible device for evaporating a composite metal film layer includes a base 1, and is characterized in that: a mother crucible 2 and 4 sub-crucible modules 3 are arranged on the base 1; A mother crucible installation groove 4 is reserved, and the mother crucible 2 is installed in the mother crucible installation groove 4; the four sub-crucible modules 3 are evenly distributed on the base around the outer contour of the mother crucible.

[0017] Each sub-crucible module 3 includes a sub-crucible base 5, a sub-crucible 6, an electron gun 7 and a drive cylinder 8; the sub-crucible base 5 is hinged on the surface of the base 1; the sub-crucible 6 and the electron gun 7 are fixed on the surface of the sub-crucible 6 base, driven The push rod of the cylinder 8 is connected to the bottom of the sub-crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com