Full-automatic two-water-temperature water boiler

A dual water temperature and water boiler technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex control systems and circuits of dual water temperature water boilers, high working temperature of water boilers, and reduced system reliability. problems, to achieve the effect of improving reliability and economy, reducing the incidence of failures, and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

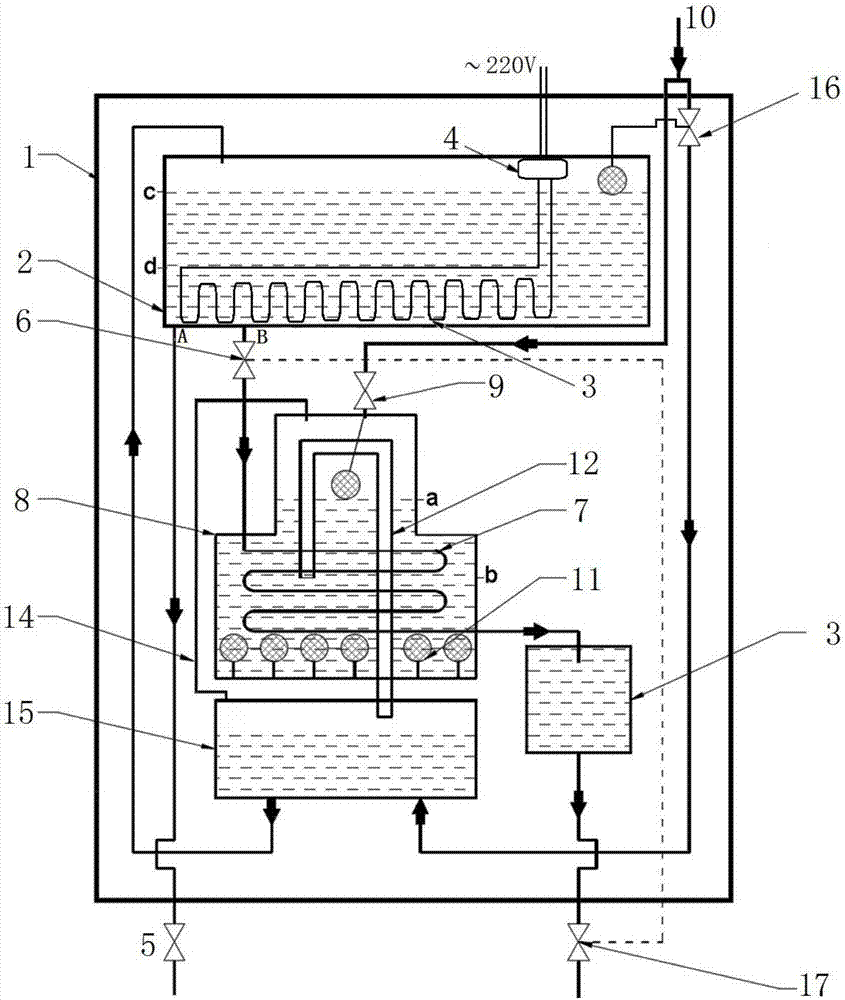

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

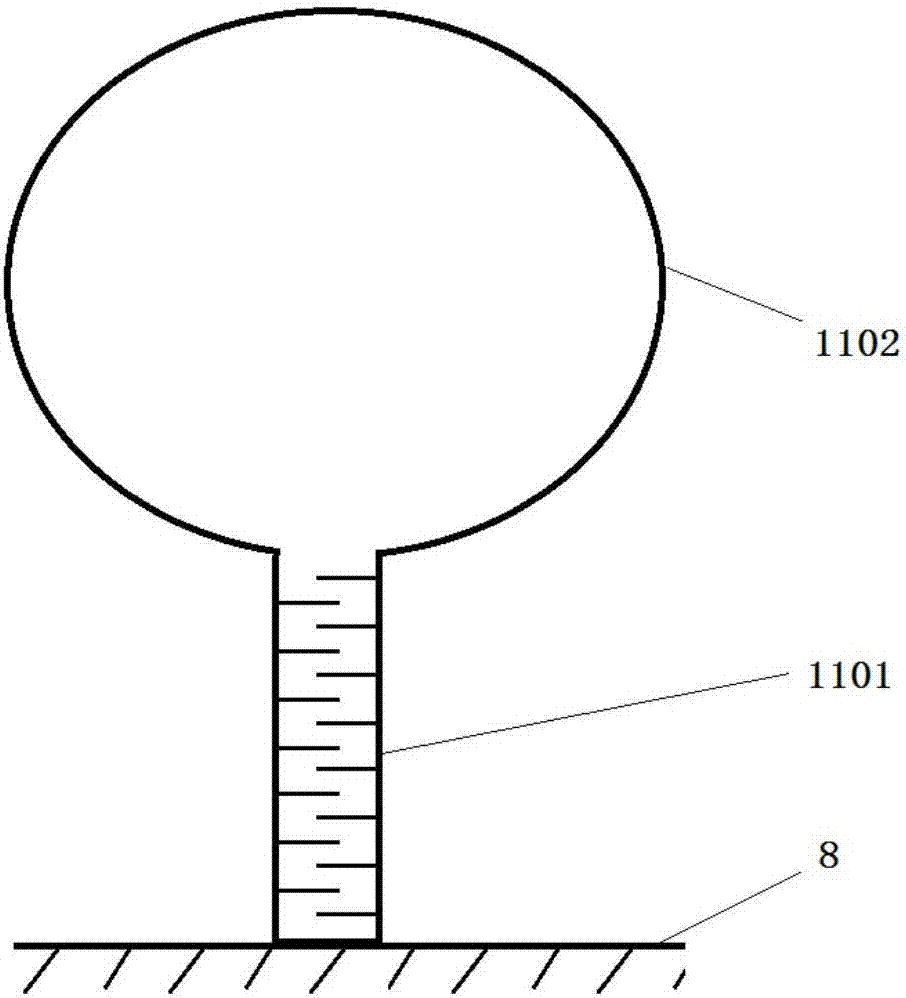

[0023] like figure 1 As shown, the full-automatic dual-water temperature water boiler of the present invention includes an insulated box 1 and a heating box 2 positioned in the insulated box 1, a heat exchange box 8, a warm water storage tank 13 and a preheated water storage tank 15; wherein, heating The box 2 is a non-closed box, and the heating box 2 is located on the top of the insulation box 1. The heating box 8 is provided with an electric heater 3 with a temperature control switch 4, and the electric heater 3 is connected to the external power supply of the insulation box 1. A heat exchange coil 7 is arranged in the heat exchange box 8, and the heat exchange coil 7 is a copper coil, and the heat exchange coil 7 is evenly arranged in the heat exchange bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com