Machine learning device, machine learning method, and fault prediction device and system

A machine learning and failure technology, applied in neural learning methods, machine learning, reasoning methods, etc., can solve problems such as lack of accuracy, difficulty in detecting abnormal sounds, and motor failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

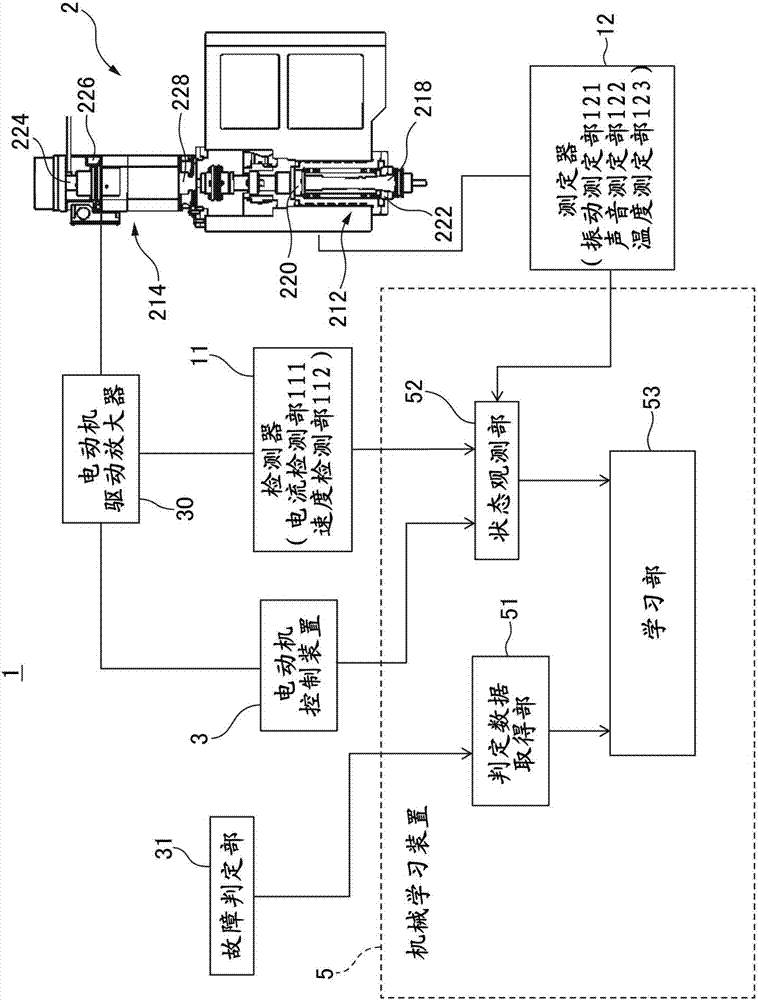

[0030] Embodiments of a machine learning device, a machine learning method, and a failure prediction device and a failure prediction system including the machine learning device according to the present invention will be described below with reference to the attached drawings. figure 1 It is a block diagram showing an example of a failure prediction system according to an embodiment, and only main components are shown in the figure. Here, the failure prediction system 1 uses the machine learning device 5 having a machine learning function to learn the failure prediction of the spindle 212 of the machine tool 2 or the motor 214 driving the spindle 212 . In addition, the failure prediction system 1 can generate failure information indicating whether the spindle 212 of the machine tool 2 or the motor 214 driving the spindle 212 has a failure or the extent of the failure based on the learning result of the machine learning device 5 .

[0031] In this specification, "machine tool" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com