A circular expansion type wiring cassette

An expansion type, cassette technology, applied in the direction of electrical components, etc., can solve problems such as difficult removal, inability to adjust the direction of the wiring cassette, complicated operation steps, etc., and achieve the effect of eliminating the difficulty of lead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

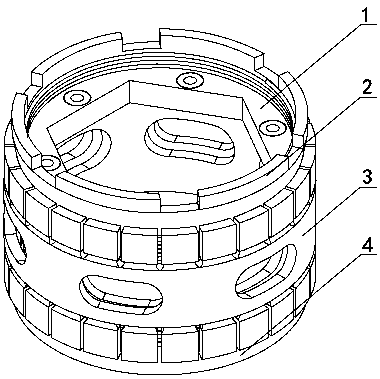

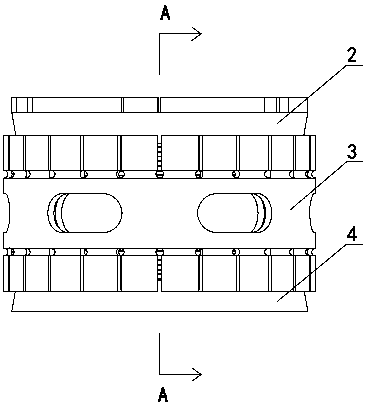

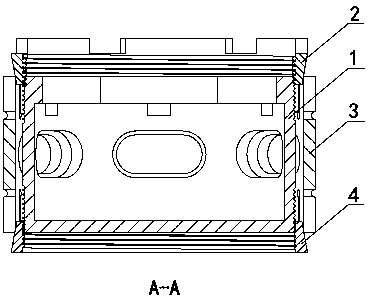

[0039] Such as Figure 1~3 As shown, a circular expansion junction box includes an outer expansion sleeve 3, an inner box body 1 is placed inside the outer expansion sleeve 3, the cross sections of the inner box body 1 and the outer expansion sleeve 3 are circular, and the inner box body There is a gap between the outer circumference of 1 and the inner circumference of the outer expansion sleeve 3. The upper and lower openings of the outer expansion sleeve 3 are respectively provided with an upper cone 2 and a lower cone 4 at the upper and lower openings of the outer expansion sleeve 3, and the upper cone 2 and the lower cone 4 enter from the corresponding ports of the outer expansion sleeve 3 respectively. The outer expansion sleeve 3 is then threadedly connected with the inner box body 1 respectively.

[0040] Such as Figure 4 As shown, the outer expansion sheath 3 includes an outer expansion sheath body 5, the outer expansion sheath body 5 is a cylindrical shape with the...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is: as Figure 8~10 As shown, one section of the lower cone 4 in the present embodiment is closed, and a base plate 17 is provided at the bottom (thicker end) of the lower cone 4, and a base plate fastening hole 18 is provided at the center of the base plate 17, and the base plate fastening hole 18 It is a hexagonal hole, and the circumferential rotation of the lower cone 4 can be realized by an Allen wrench matched with the fastening hole 18 of the bottom plate. At the same time, the closed end of the inner box body 1 is provided with a through hole with a diameter larger than the fastening hole 18 of the bottom plate and corresponding to the front and back of the fastening hole 18 of the bottom plate.

[0054] When assembling the circular expansion type junction box, after the pre-tightening is completed, the hexagonal wrench can be used to pass through the inner box body 1 and then be installed with the fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com