Brushless motor

A motor and housing technology, applied in the field of brushless motors, can solve problems such as difficulty in securing space, and achieve the effect of smooth assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A brushless motor as an embodiment will be described with reference to the drawings. The embodiments shown below are examples at most, and it is not intended to exclude various modifications and technical applications not explicitly described in the following embodiments. Each structure of this embodiment can be implemented with various modifications within the range which does not deviate from the gist. In addition, trade-offs can be made as needed, or combinations can be made as appropriate. In the following description, the axial direction of the motor is also referred to as a "vertical direction". In addition, the bottom side of the case is described as "downward", and the opening side of the case is described as "upper".

[0030] [1. Composition]

[0031] [1-1. Overall composition]

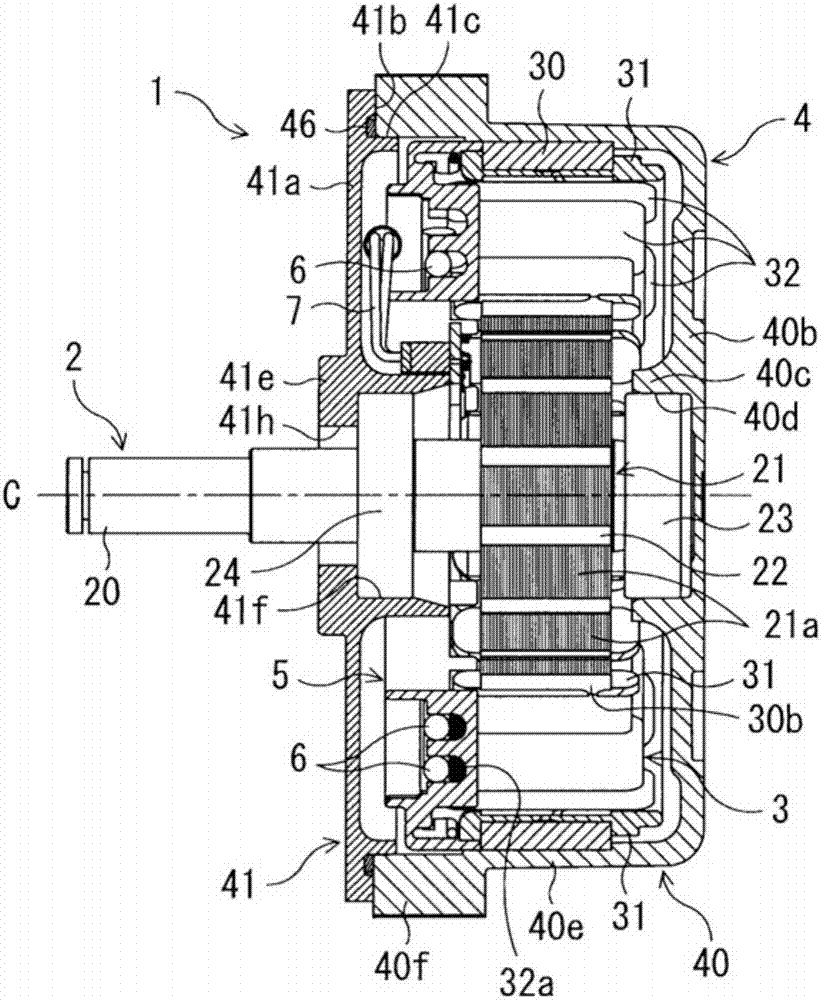

[0032] figure 1 It is an axial cross-sectional view of a brushless motor 1 (hereinafter referred to as "motor 1") of the present embodiment. The motor 1 is an inner rotor type br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com