Mixing device

A technology of matching connection and sliding cavity, applied in the field of fruit and vegetable salad machines, can solve the problems of cumbersome and laborious operation process, unable to ensure food safety, and unable to discharge by itself when stirring, so as to achieve uniform mixing of raw materials, improve work efficiency, food safety, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

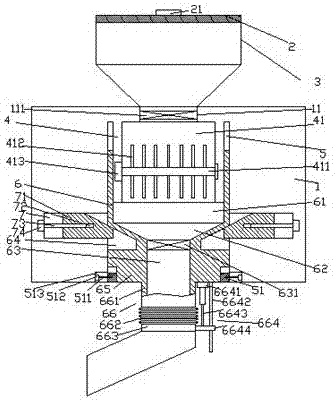

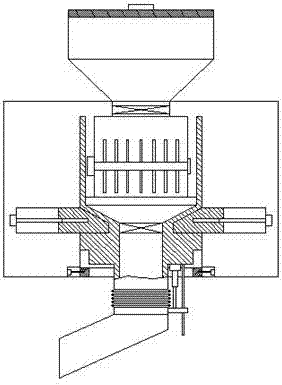

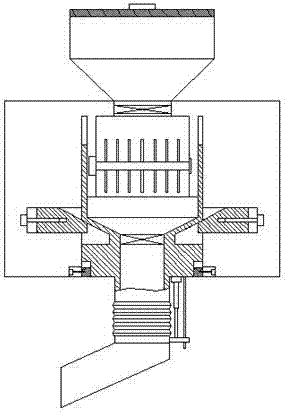

[0023] Such as Figure 1-Figure 5 As shown, a mixing device of the present invention includes a cup body 1 and a filter bucket 3 fixedly arranged on the top of the cup body 1, the top cover of the filter bucket 3 is provided with an end cover 2, and the end cover 2. A grip ring 21 is provided at the center of the top end face, through the cover of the end cover 2, it can effectively prevent dust or pollutants from falling into the filter bucket 3 during use of the device and cause food safety hazards, thereby To ensure the cleanliness of the device during use and improve food safety, the cup body 1 is provided with a first sliding chamber 5, and a flange block 51 is provided at the bottom side of the first sliding chamber 5, so that The inner walls of the left and right sides of the first sliding chamber 5 near the bottom are provided with sliding grooves 7 correspondingly. The first sliding chamber 5 is provided with a sliding member 6 that is connected by sliding and matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com