Medical pulverizer provided with multi-stage discharging channels

The technology of a blanking channel and a pulverizer is applied in cleaning methods and utensils, grain processing, chemical instruments and methods, etc., and can solve multi-channel simultaneous sorting and blanking that cannot be graded, low blanking efficiency, and increased work It can save operation time, improve efficiency and reduce dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

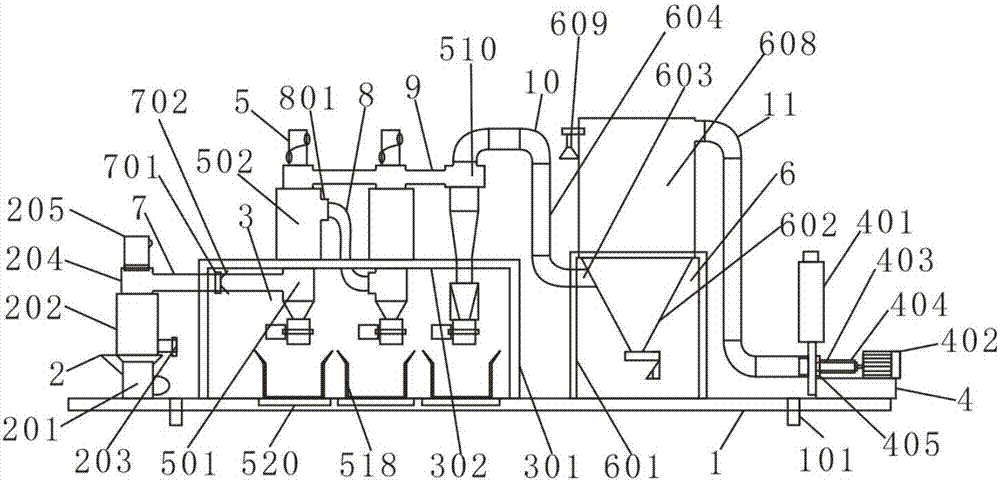

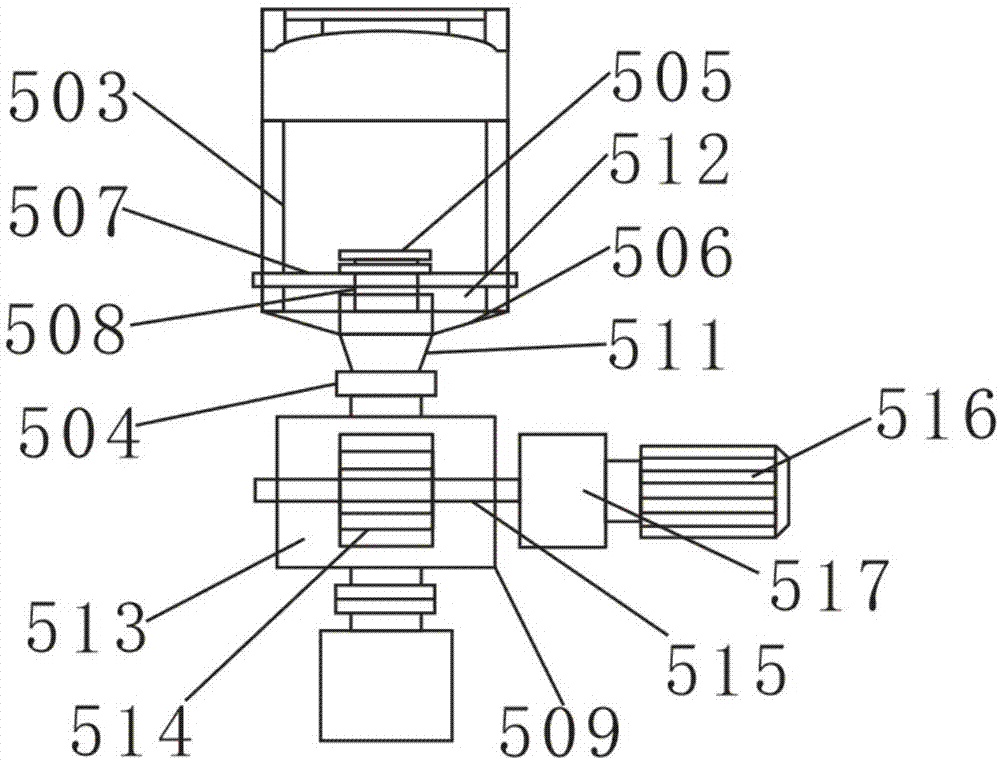

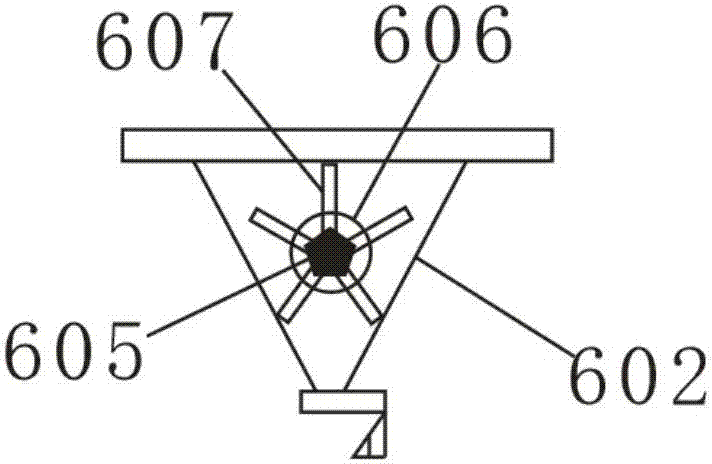

[0040] Such as Figure 1 to Figure 6 As shown, the present invention provides a medical pulverizer with a multi-stage blanking channel, connected to the discharge port of the pulverizer, including a main base 1, a primary feeding device 2, a blanking gantry 3 and a dust collection device 4, The specific structure and functions of the primary feeding device 2 will be specifically described later. The primary feeding device 2, the blanking gantry 3 and the dust collection device 4 are fixedly installed on the upper surface of the main base 1 in turn, and several multi-stage blanking channels 5 are arranged side by side on the blanking gantry 3, and on the blanking gantry 3 A vibrating sorting dust raising device 6 is also fixedly installed between the dust collecting device 4, the primary feeding device 2 and the multi-stage blanking channel 5 are connected by a crushing discharge pipe 7, and the adjacent multi-stage blanking channel 5 The collection feed pipe 8 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com