Pin shaft pulling device and operation method thereof

A technology for extracting devices and pins, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult extraction, high product scrapping rate, increased maintenance costs, etc., and achieve the effect of saving maintenance costs and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

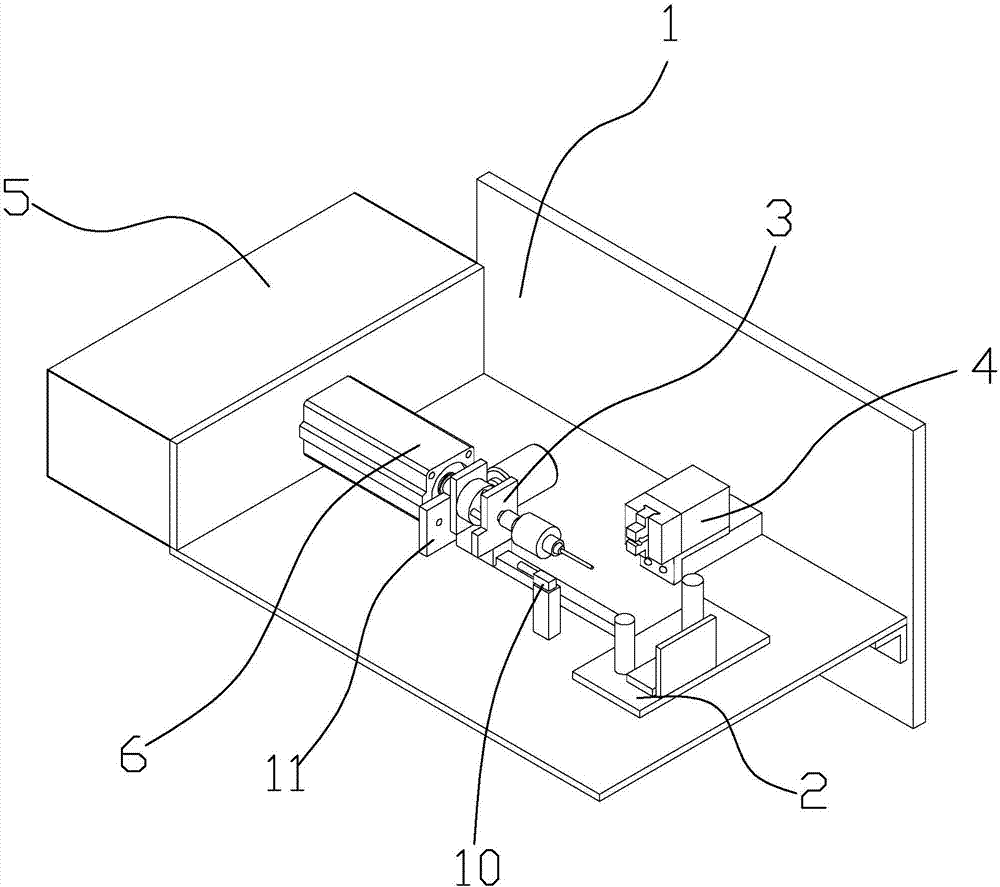

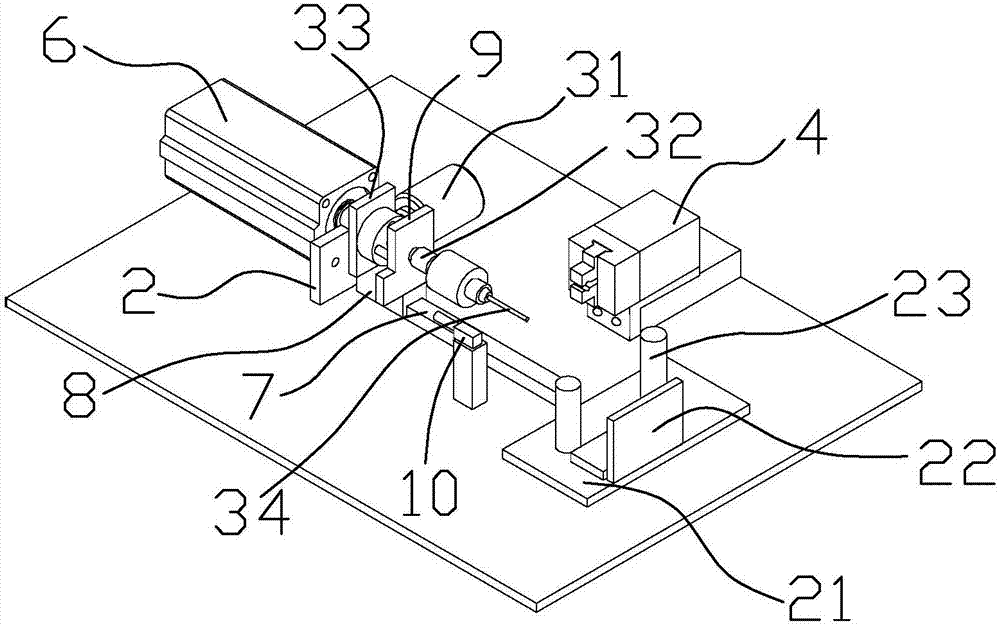

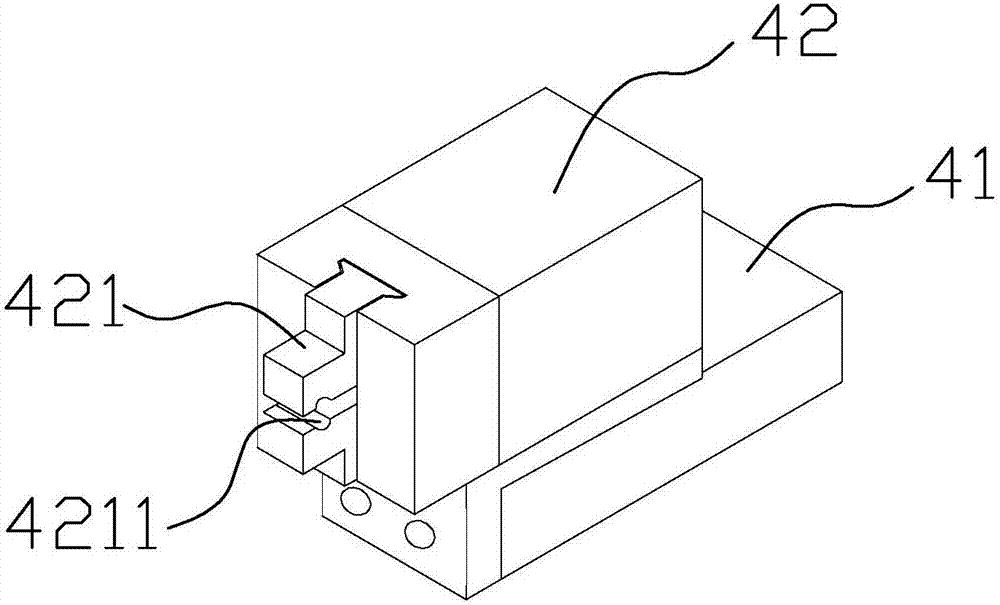

[0027] Such as Figure 1~3 As shown, a pin extracting device provided by the present invention includes a support plate 1, and the support plate 1 is provided with a positioning mechanism 2, a pin pulling mechanism 3, an out-of-pin mechanism 4 and an electric control box 5; The support plate 1 is provided with a driving cylinder 6 for driving the pin pulling mechanism 3 to reciprocate toward the position of the positioning mechanism 2. One end of the driving cylinder 6 is fixed on the side wall of the support plate 1, and the other end is fixed on the side wall of the support plate 1 through the fixing plate 11. On the support plate 1, when the product is fixed on the positioning mechanism 2, the driving cylinder 6 drives the pin pulling mechanism 3 to pull out the pin shaft in the product, and the pin removal mechanism 4 is used to drop the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com