Automatic connecting and disconnecting device used for steam-curing car

A technology for automatic connection and separation devices, which is applied to ceramic molding machines and manufacturing tools to achieve low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

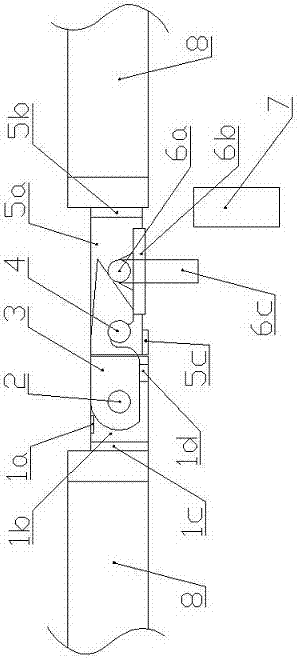

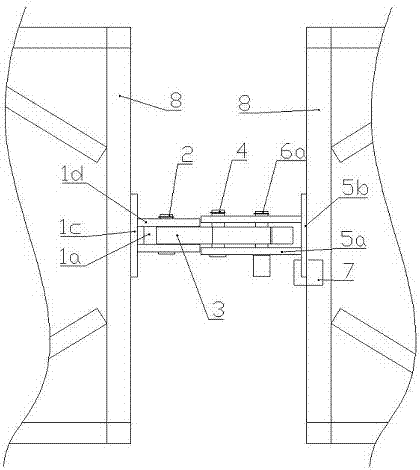

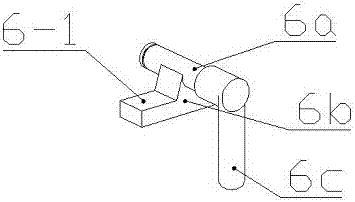

[0020] The accompanying drawings show the technical solution of the present invention and its implementation examples, and the implementation details and working principle will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the present invention provides an automatic connection and separation device for steam curing vehicles, which includes a hook seat assembly arranged at the front of the vehicle body, a decoupling seat assembly arranged at the rear of the vehicle body, and a decoupling assembly arranged at a predetermined position on the running track of the steam curing vehicle , in this example, because of the symmetry of the car body, it is assumed that the installation side of the hook seat assembly is the front end of the car, and the installation side of the decoupling seat assembly is the tail of the car.

[0022] The hook assembly includes a hook seat, a hook pin shaft 2, and a hook 3. The hook seat inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com