Injection molding machine capable of forming colored-texture plastic product

A technology of plastic products and injection molding machines, applied in the field of injection molding machines, can solve problems such as insufficient raw materials, inability to form colored textures, and inability to automatically remind, etc., to achieve the effect of reducing the degree of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

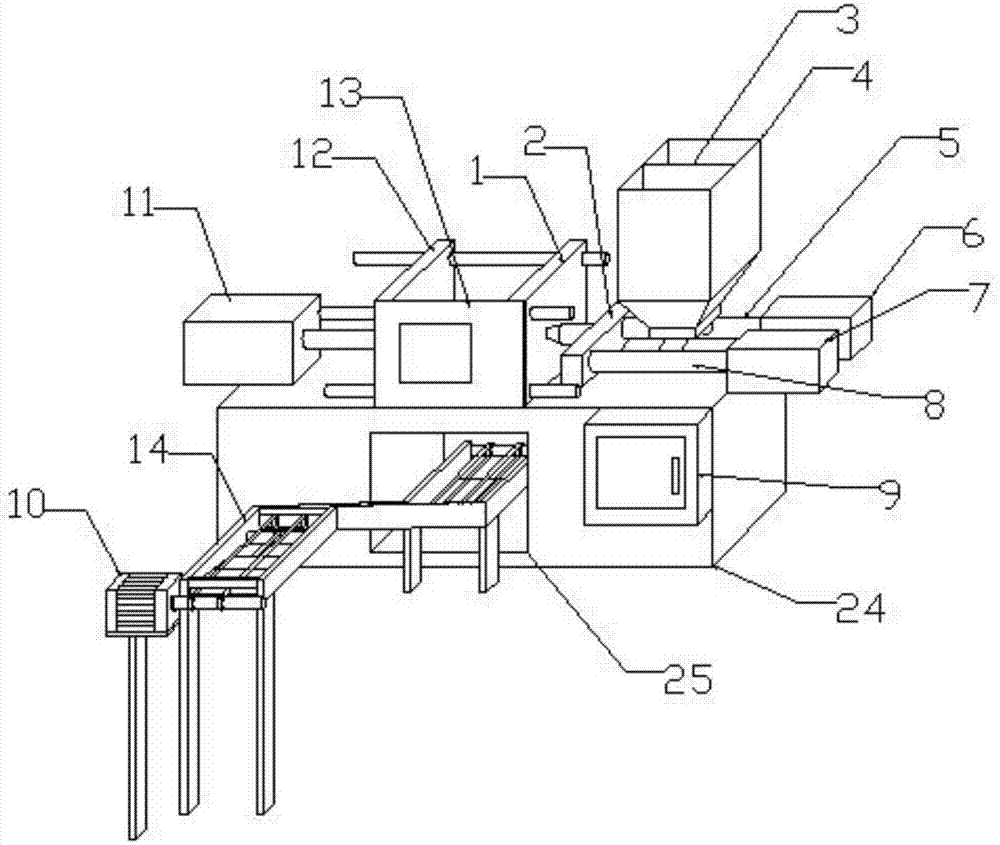

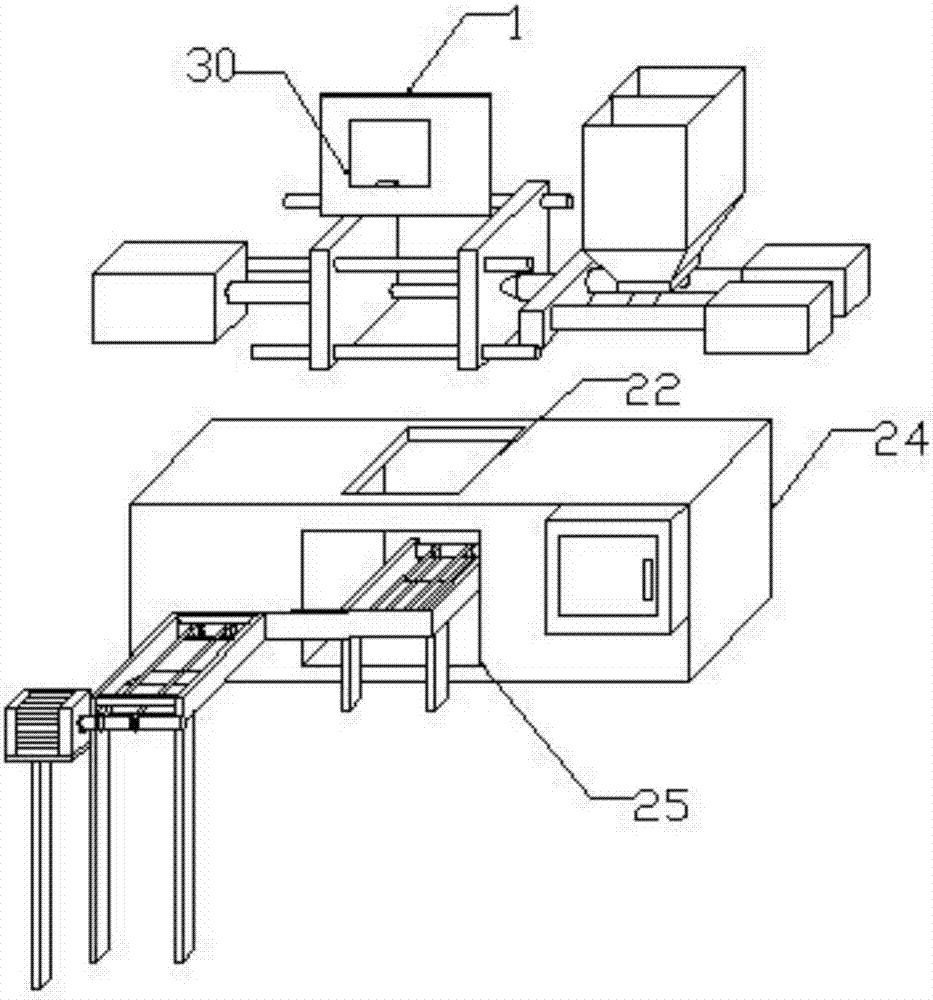

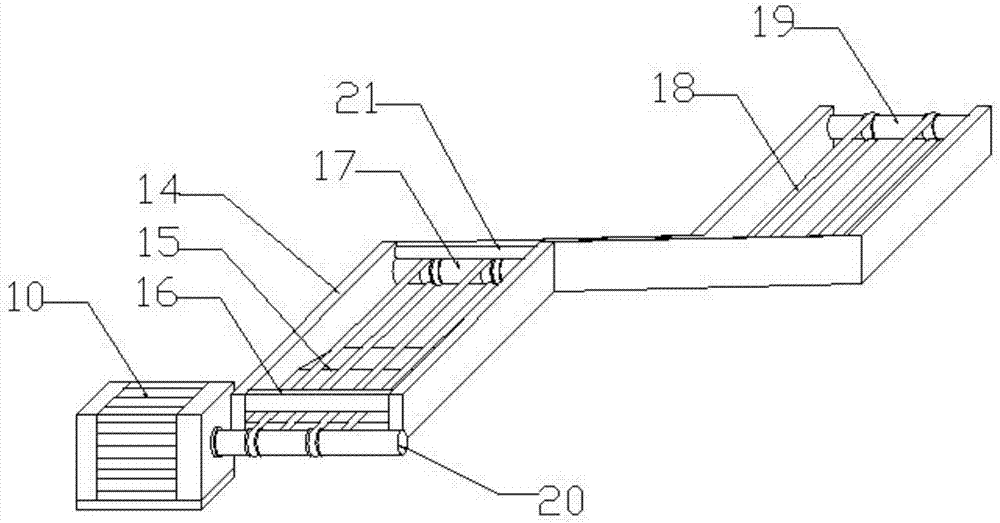

[0022] Example: such as Figure 1-6 As shown, the present invention is a kind of injection molding machine capable of forming colored textured plastic products, comprising a machine tool 24, one side of the machine tool 24 is provided with a material receiving groove 25, and the top of the machine tool 24 is provided with a material receiving port 22, and the material receiving port 22 is connected to the The material receiving trough 25 is connected, and the two sides of the material receiving port 22 are respectively provided with a movable template 12 and a fixed template 1, and the opposite side of the movable template 12 and the fixed template 1 is respectively provided with a mold core 26 and a mold cavity 27. 12 is provided with a third hydraulic unit 11, the outside of the fixed plate 1 is provided with nozzles 2, and the nozzles 2 communicate with the first injection assembly 5 and the second injection assembly 8, the first injection assembly 5 and the second injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com