Connecting device of high-voltage wiring harness of new energy automobile

A technology for new energy vehicles and high-voltage wiring harnesses, which is applied in vehicle components, transportation and packaging, circuits or fluid pipelines, etc., and can solve problems such as no guarantee of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

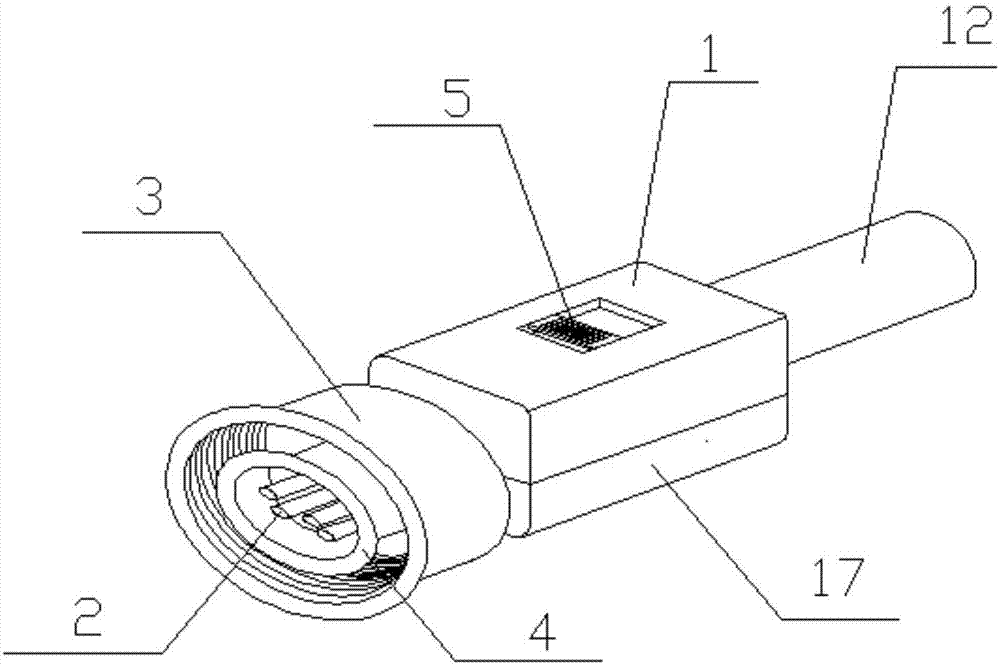

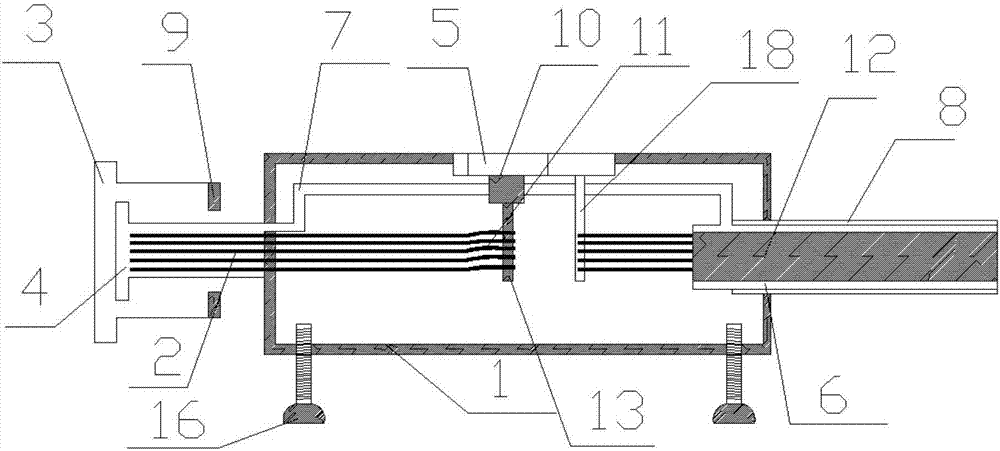

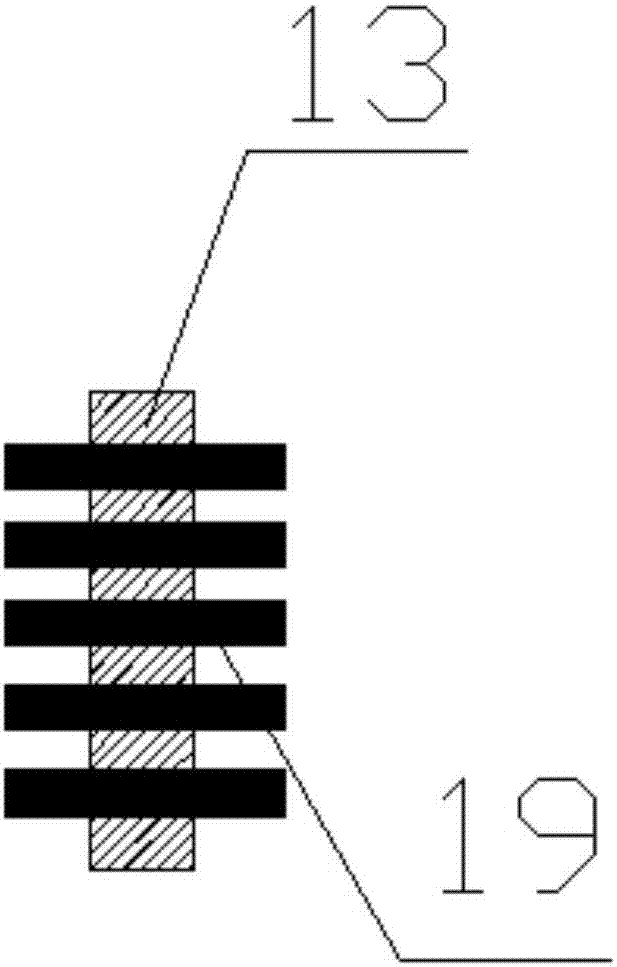

[0021] Such as Figure 1 to Figure 3 As shown, a connection device for high-voltage wire harnesses of new energy vehicles includes a junction box 1 and a junction head 4. 2. The junction box 1 is provided with a rear cover 17, the top of the junction box 1 is provided with a sliding switch 5, the bottom of the switch 5 is provided with a sliding block 10, and the sliding block 10 is provided with a copper contact The iron sheet 13 of the head 19, the end of the collection core 2 is connected with a flexible wire 11, the flexible wire 11 is connected with the copper contact head 19, the tail of the junction box 1 is provided with an opening, and the high-voltage wire harness 12 passes through the opening and the collection The junction box 1 is connected, and the junction box 1 is also provided with a conductive sheet 7 and a collection sheet 18. The conductive sheet 7 is connected to the outer core 6 of the high-voltage wire harness 12 and the assembly head 4, and the collecti...

Embodiment 2

[0027] Such as Figure 3 to Figure 5 As shown, a connection device for high-voltage wire harnesses of new energy vehicles includes a junction box 1 and a junction head 4. 2. The junction box 1 is provided with a rear cover 17, the top of the junction box 1 is provided with a sliding switch 5, the bottom of the switch 5 is provided with a sliding block 10, and the sliding block 10 is provided with a copper contact The iron sheet 13 of the head 19, the end of the collection core 2 is connected with a flexible wire 11, the flexible wire 11 is connected with the copper contact head 19, the tail of the junction box 1 is provided with an opening, and the high-voltage wire harness 12 passes through the opening and the collection The junction box 1 is connected, and the junction box 1 is also provided with a conductive sheet 7 and a collection sheet 18. The conductive sheet 7 is connected to the outer core 6 of the high-voltage wire harness 12 and the assembly head 4, and the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com