Cut-off device for pipeline

A kind of interceptor and pipeline technology, applied in the direction of fluid distribution valve, sliding valve, functional valve type, etc., can solve the problems of loss, water overflow, safety accident economy, etc., to avoid safety accidents and waste of water resources, good prevention spillover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

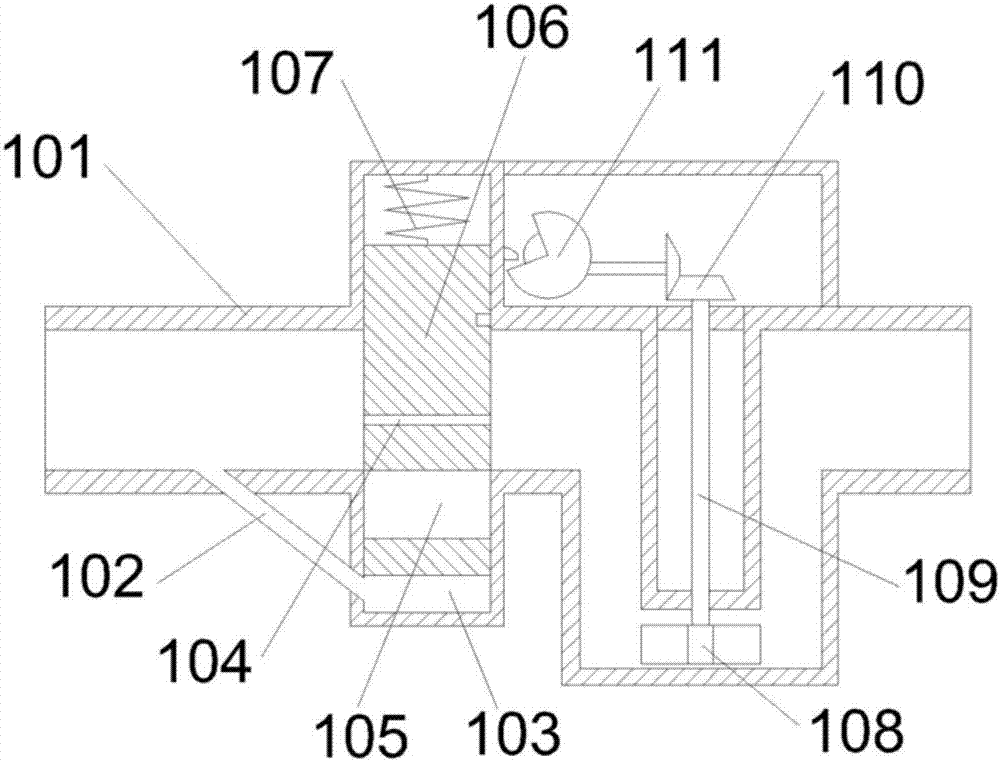

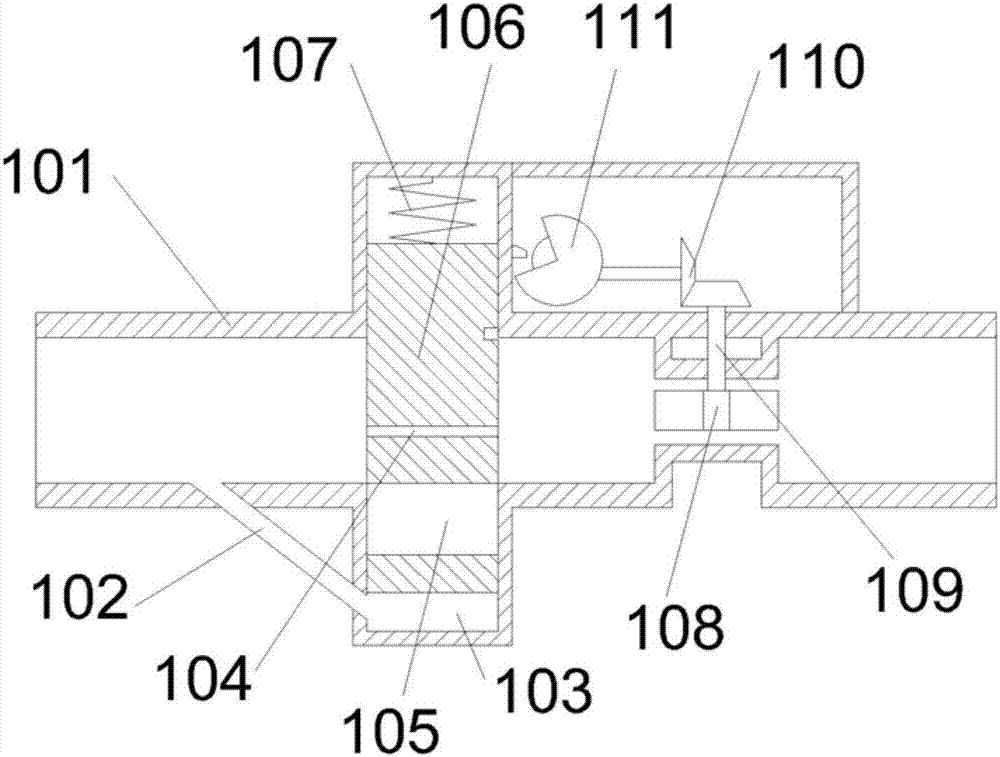

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides a pipeline interceptor, which includes: a metering impeller, a control mechanism, and a stop piston arranged on the pipeline for controlling the opening / closing of the pipeline; the opposite sides of the pipeline are respectively provided with The first chamber and the second chamber, and the first chamber and the second chamber communicate with the pipeline; the outer wall of the stop piston is attached to the inner wall of the first chamber and the second chamber; the stop piston One end of the stop piston is set in the first chamber through the elastic reset mechanism; when the stop piston is in the closed state, the other end of the stop piston is located in the second chamber, and forms a pressure chamber with the inner side wall of the second chamber; the pressure chamber passes the pressure The return pipe communicates with the pipeline, and the connecting end of the pressure return pipe and the p...

Embodiment 2

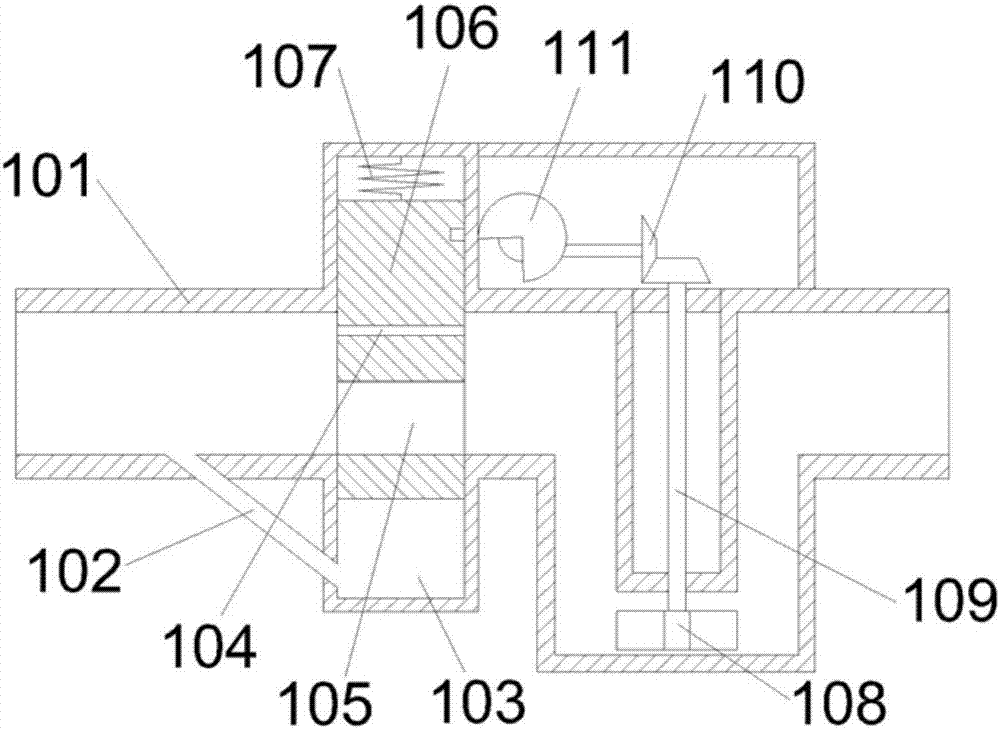

[0041]This embodiment provides a pipeline interceptor, which includes: a metering impeller, a control mechanism, and a stop piston arranged on the pipeline for controlling the opening / closing of the pipeline; the opposite sides of the pipeline are respectively provided with first cavities chamber and the second chamber, and the first chamber and the second chamber are in communication with the pipeline; the outer wall of the stop piston is attached to the inner wall of the first chamber and the second chamber; one end of the stop piston passes through The elastic reset mechanism is set in the first chamber; when the stop piston is in the closed state, the other end of the stop piston is located in the second chamber, and forms a pressure chamber with the inner side wall of the second chamber; The pipeline is connected, and the connecting end of the pressure return pipe and the pipeline is located downstream of the stop piston.

[0042] Wherein, the stop piston is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com