Multi-functional shredding and slicing device with two feeding holes

A slicing device and multi-functional technology, which is applied in the field of multi-functional shredding and slicing devices with double feed ports, can solve the problems of single product function and difficulty in meeting the user's requirements for multiple processing of food materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now with reference to the accompanying drawings, the embodiments of the present invention will be described in detail.

[0028] For the sake of illustration, the width, length, thickness, etc. of some components in the schematic diagrams are sometimes exaggerated.

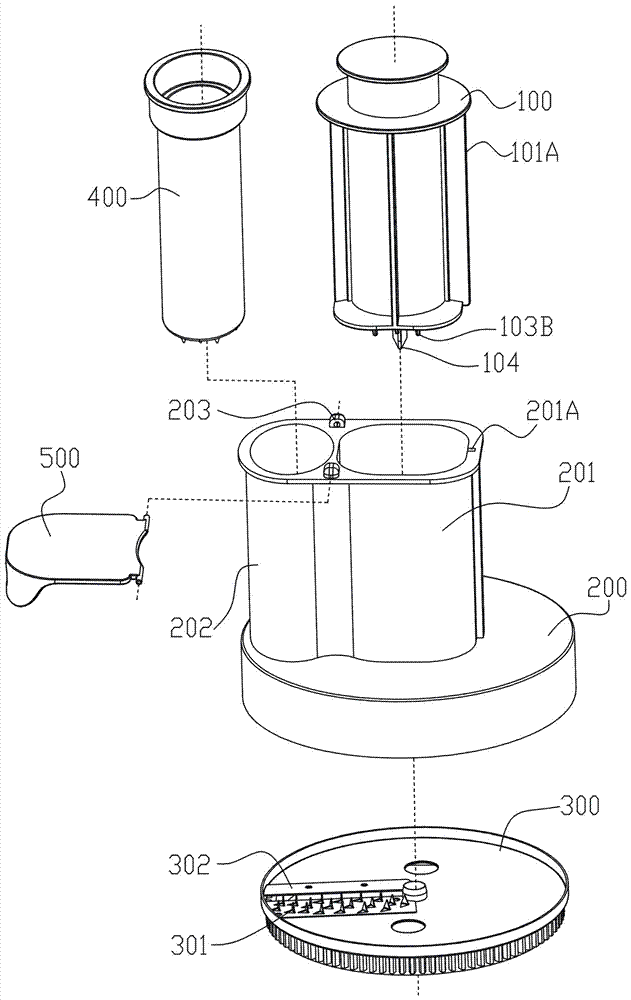

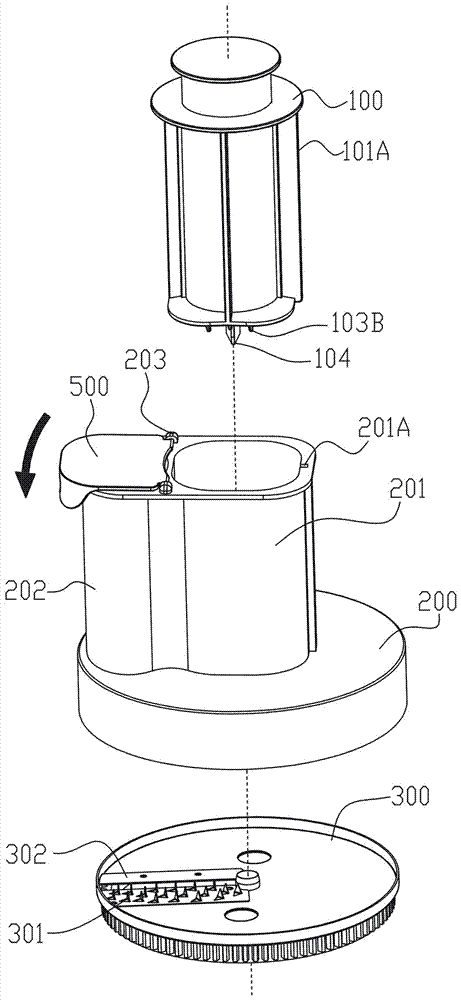

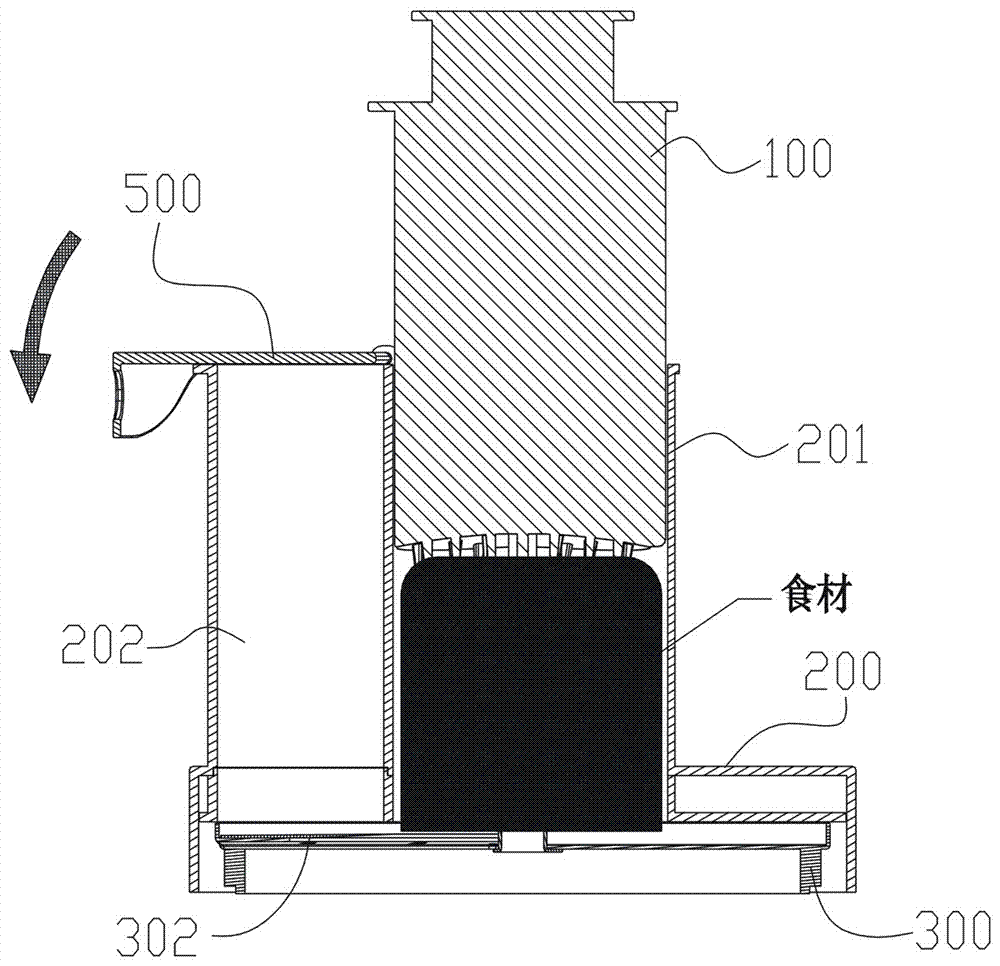

[0029] Such as Figure 1 to Figure 5 As shown, a multifunctional shredding and slicing device provided with double feeding ports includes a processing upper cover 200 and a cutting cutter head 300, and the processing upper cover 200 is covered on the cutting cutter head 300, and the center feeds The cylinder 201 is arranged on the processing upper cover 200 and is coaxial with the cutting cutter head 300; the eccentric feeding cylinder 202 is arranged on the processing upper cover 200 and deviates from the axis of the cutting cutter head 300; The central push rod 100 cooperates with the central feeding cylinder to push the food material for spiral cutting, and the lower end of the central push rod 100 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com