Preparation method of cathode for micro-electrolytic wire cutting carbon nanotube fiber tool

A technology of carbon nanotube fiber and tool cathode, which is applied in the direction of electrode manufacturing, electric processing equipment, processing electrodes, etc., can solve the problems of electrolyte update difficulty, poor processing stability, etc., and achieve strong implementability, low cost, and simple control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The three-dimensional motion control axes X-axis 26 , Y-axis 25 , and Z-axis 24 are installed on the machine tool body 27 , and the machine tool body 27 is fixed on the air-floating platform 18 . The three-dimensional motion control axis is controlled by the industrial computer 22 through the motion control card 23 .

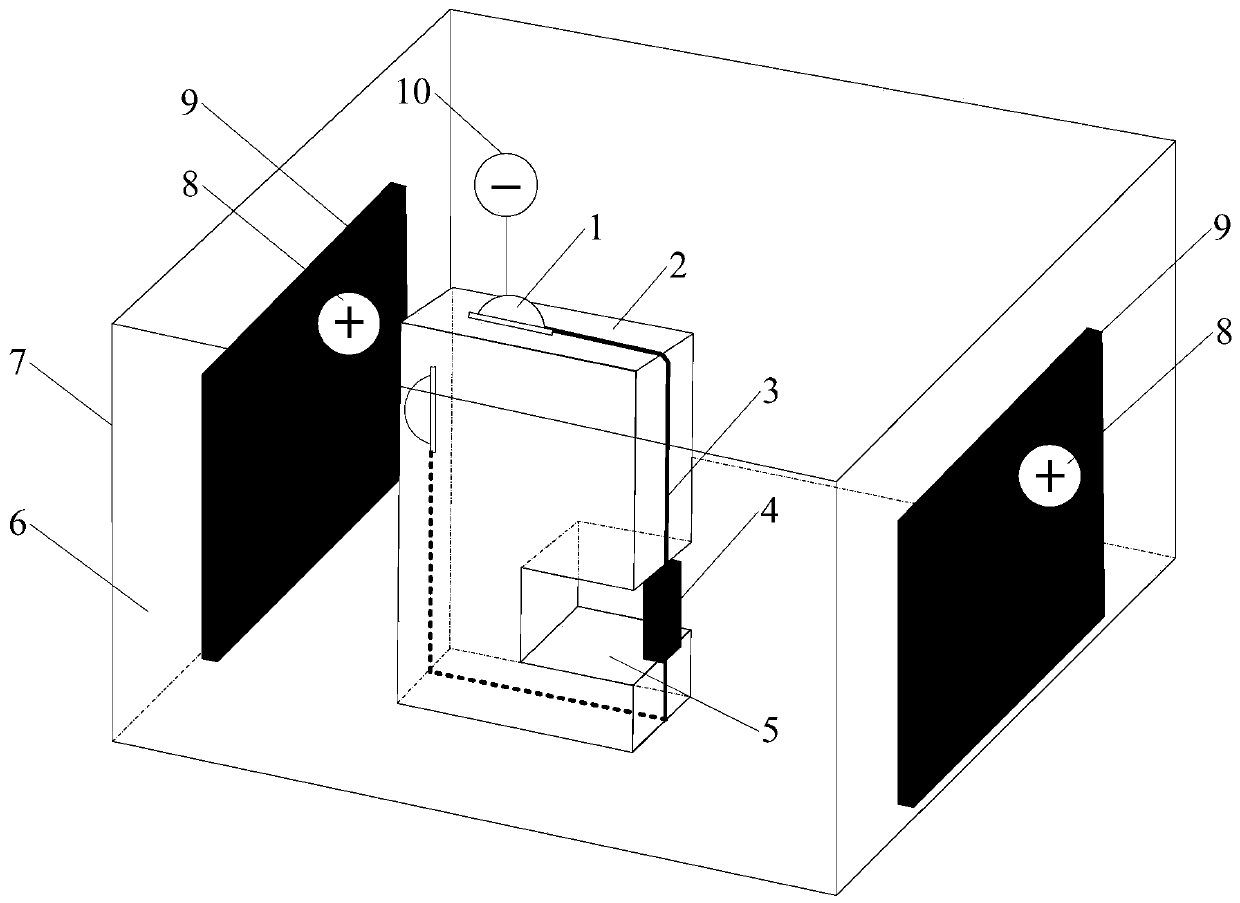

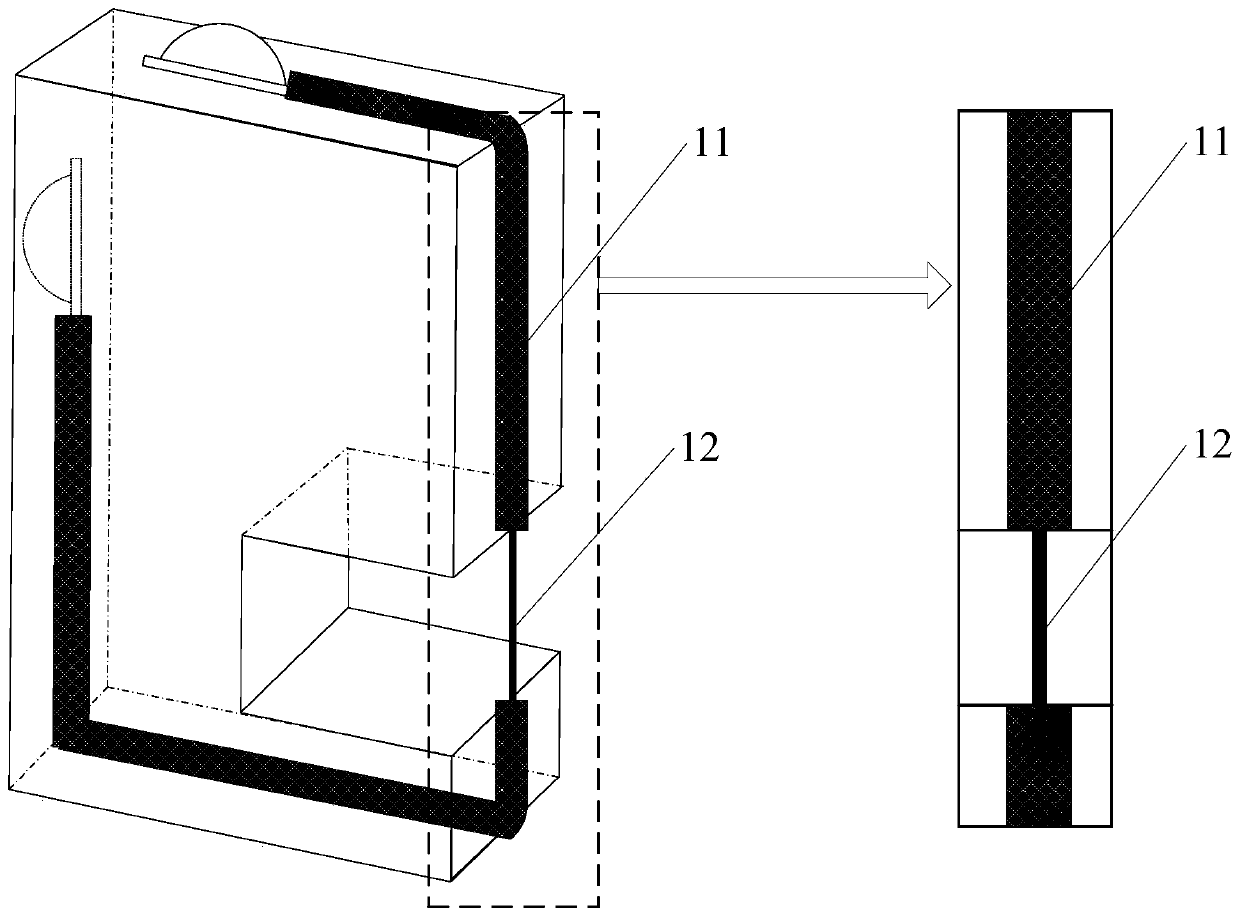

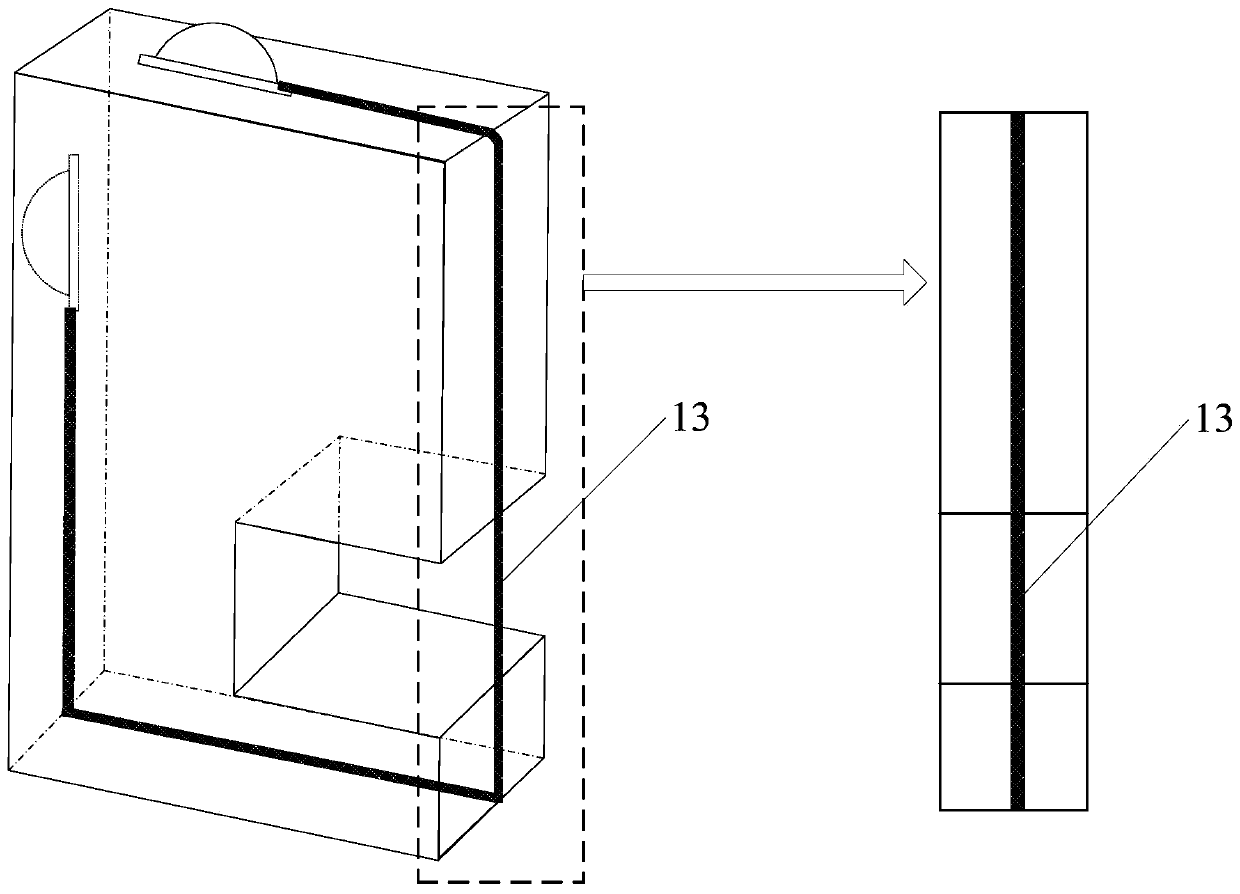

[0030] (1) Install the carbon nanotube fiber 3 on the wire electrode holder 2 and immerse it in the electroplating tank 7 filled with the electroplating solution 6 . The carbon nanotube fiber 3 is prepared by the "spinning" method of arrayed carbon nanotubes, the surface morphology is helical, and the diameter is 5-100 μm; the metal plate 9 can be silver, nickel or copper, and the electroplating solution 6 contains Metal plate 9 is a mixed solution of the same metal element ions.

[0031] (2) Connect the metal plate 9 to the positive electrode 8 of the DC power supply, connect the carbon nanotube fiber 3 to the negative electrode 10 of the DC power suppl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com