Method and device for control over icing prevention and generator

A control method and control device technology, applied in the direction of refrigerators, damage protection, refrigeration components, etc., can solve the problems of easy freezing of cooling water, achieve stable water output, solve the effects of easy freezing of cooling water, and unobstructed pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

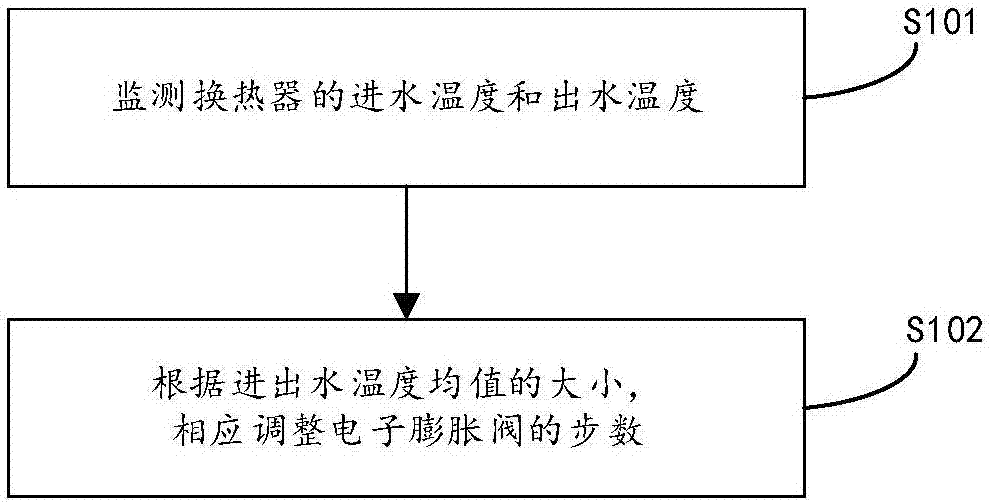

[0023] figure 1 is a flowchart of an anti-icing control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0024] Step S101, monitoring the inlet water temperature and outlet water temperature of the heat exchanger;

[0025] Step S102 , according to the average value of the inlet and outlet water temperatures, correspondingly adjust the number of steps of the electronic expansion valve. Among them, the average value of the inlet and outlet water temperature = (inlet water temperature + outlet water temperature) / 2.

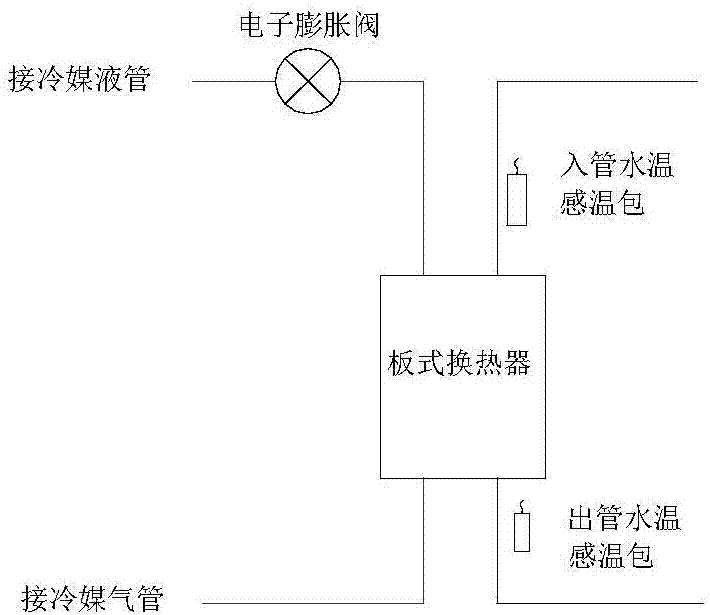

[0026] In this embodiment, the number of steps of the electronic expansion valve is adjusted by the temperature of the inlet and outlet water of the heat exchanger, which solves the problem th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com