Workpiece detection equipment

A workpiece detection and equipment technology, applied in the field of machinery, can solve the problem of high labor costs and achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

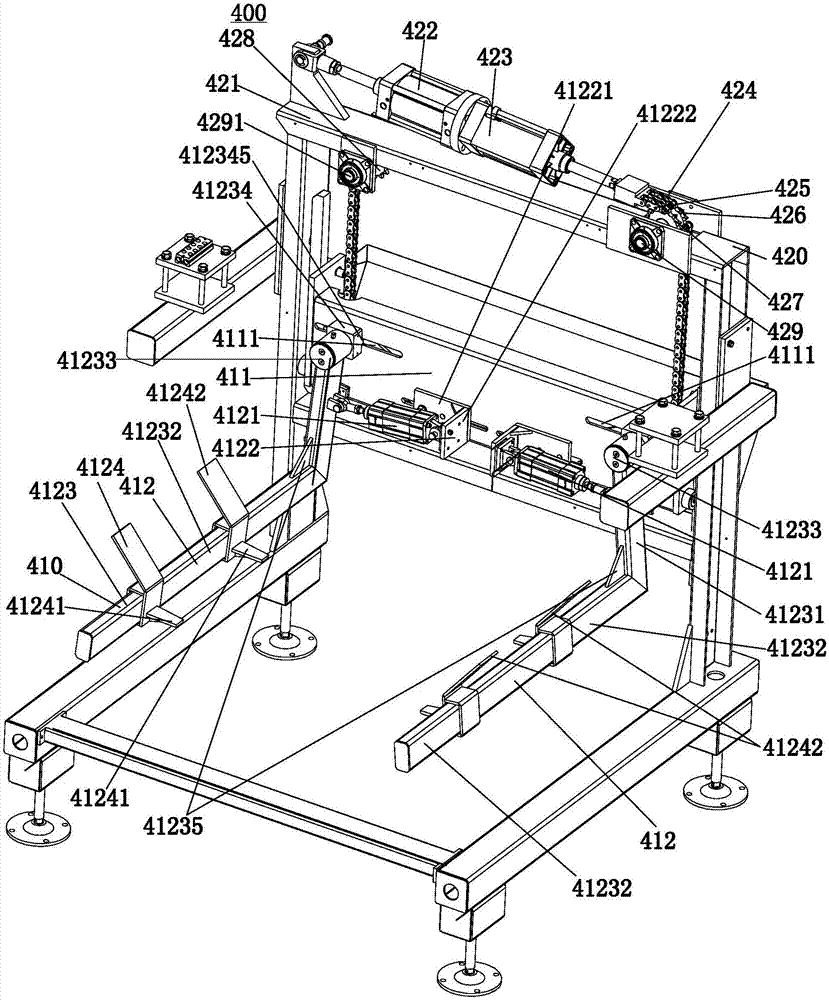

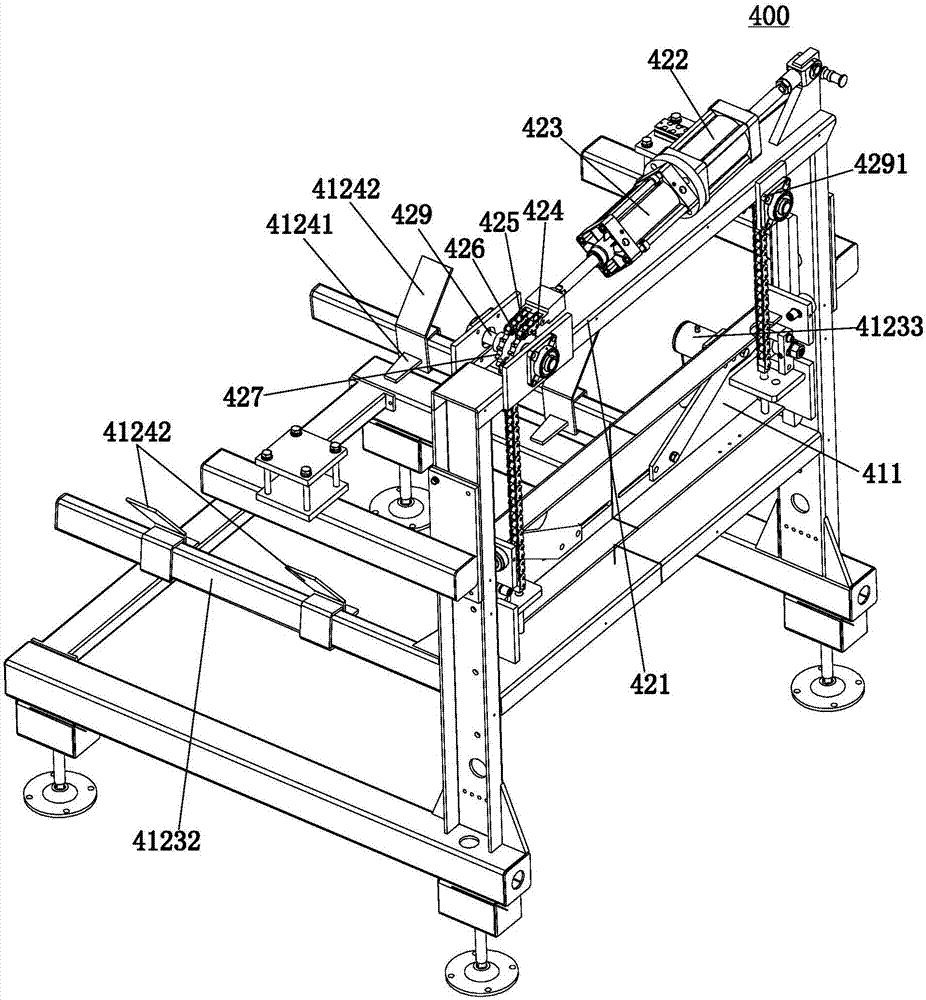

[0013] reference Figure 1 to Figure 3 The workpiece detection equipment 410 of the present invention includes a supporting back plate 411 and two plug-in arm assemblies 412 symmetrically connected to both sides of the front wall of the supporting back 411.

[0014] The plug-in arm assembly 412 includes a plug-in cylinder 4121, a plug-in cylinder base 4122, a plug-in arm 4123, and at least two plug-in kits 4124. The plug-in cylinder base 4122 includes a vertical fixing plate 41221 and a cylinder mounting plate 41222 extending vertically forward from the inner end of the vertical fixing plate 41221. The vertical fixing plate 41221 is fixed to the front side wall of the supporting back plate 411. The fixed end of the plug-in cylinder 4121 is fixedly connected to the cylinder mounting plate 41222 against a side wall of the vertical fixing plate 41221. The supporting back plate 411 is provided with a horizontal sliding groove 4111 above the outer side of the plug-in cylinder 4121. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com