A girder erection method and a bridge erection machine for the working condition of a large longitudinal gradient

A bridge erecting machine and working condition technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., and can solve problems such as how to construct bridge erecting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

[0043] In view of the force bearing form of the front outriggers of the current bridge erecting machine, the lower part of the front outriggers of this application utilizes sliding friction to form a rigid connection with the beam; It is connected with the square column by a slipknot to form a flexible structure, and the height can be changed up and down.

[0044] And utilizing the front outrigger whose height can be changed up and down, the present application proposes the following beam erecting method under the working condition of large longitudinal slope.

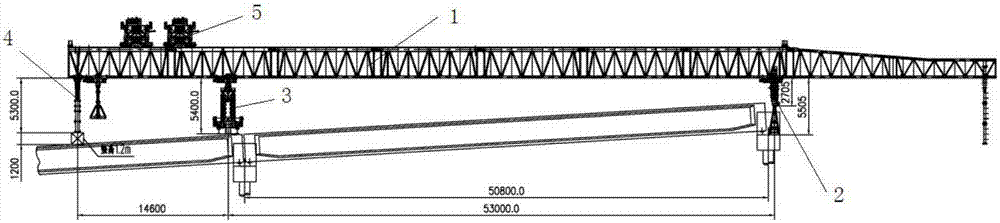

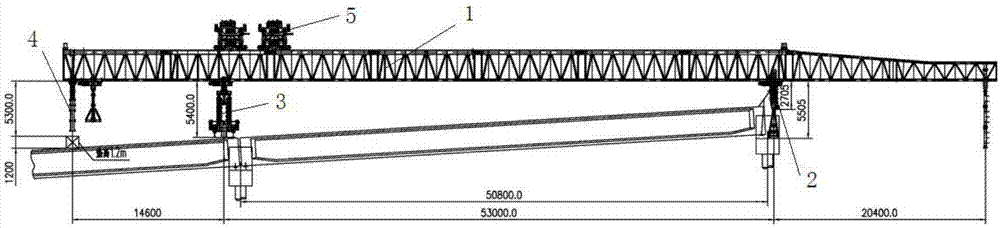

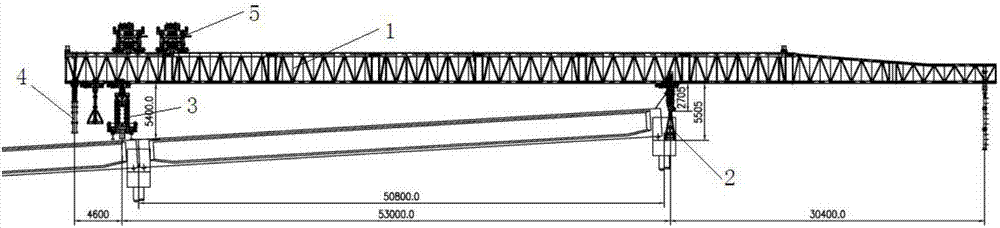

[0045] This application is used in the girder erection method under the working condition of large longitudinal slope, including the following 15 steps, respectively with Figure 1 to Figure 15 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com