Fixing assembly for road sign

A technology for road signs and fixing components, applied in roads, roads, road signs, etc., can solve problems such as potential safety hazards, time-consuming and labor-consuming operations, and damage to pedestrians and vehicles, so as to prevent loosening, improve accuracy, and improve installation The effect of fastening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

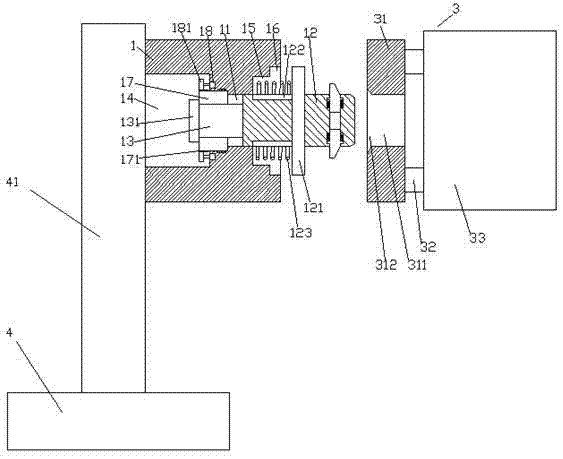

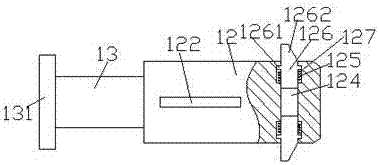

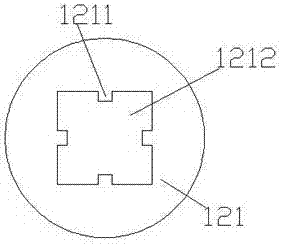

[0022] Such as Figure 1-Figure 5 As shown, a road sign fixing assembly of the present invention includes a sign kit 3 and a fixing kit 1, the left end surface of the fixing kit 1 is fixedly connected with a pillar 41, and the fixing kit 1 is fixedly connected to the pillar 41, the bottom end of the pillar 41 is fixedly provided with a base 4, and the indicator set 3 is composed of an engaging plate 31, an indicating plate 33 and an engaging rod 32 arranged between the engaging plate 31 and the indicating plate 33. Synthesis, the fixed kit 1 is provided with a slide bin 11, the fixed kit 1 on the left side of the slide bin 11 is provided with a placement groove 14, and the fixed kit 1 on the right side of the slide bin 11 is provided with The first empty slot 15, the right side of the first empty slot 15 is provided with a second empty slot 16, a locking rod 12 is slidingly connected in the sliding chamber 11, and the left end surface of the locking rod 12 is fixedly provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com