Two-way self-locking electric push rod

An electric push rod, two-way self-locking technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high cost, difficult push rod, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

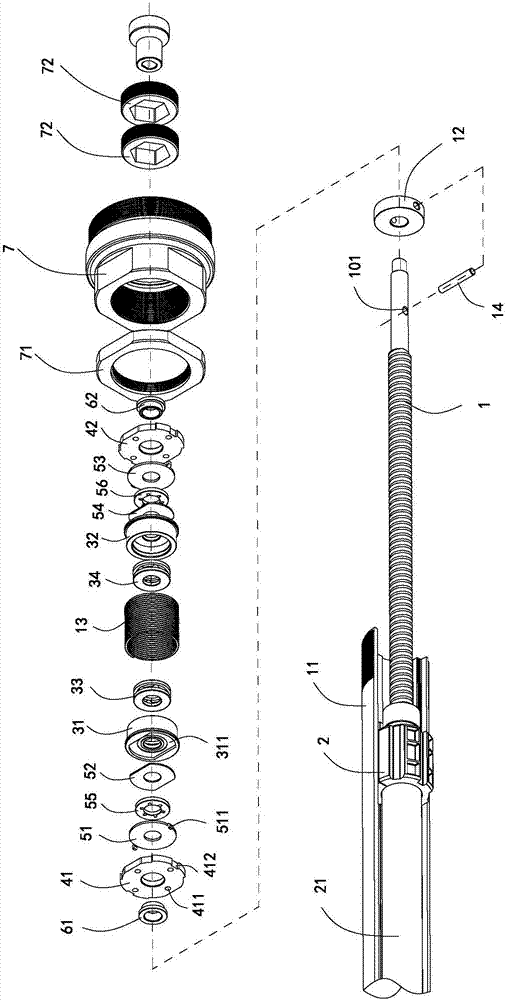

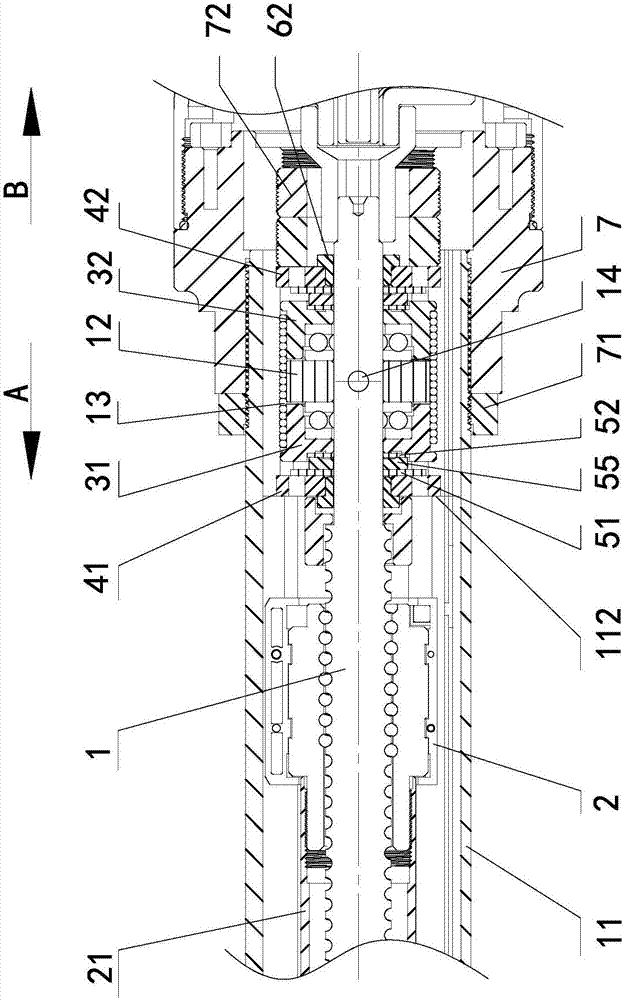

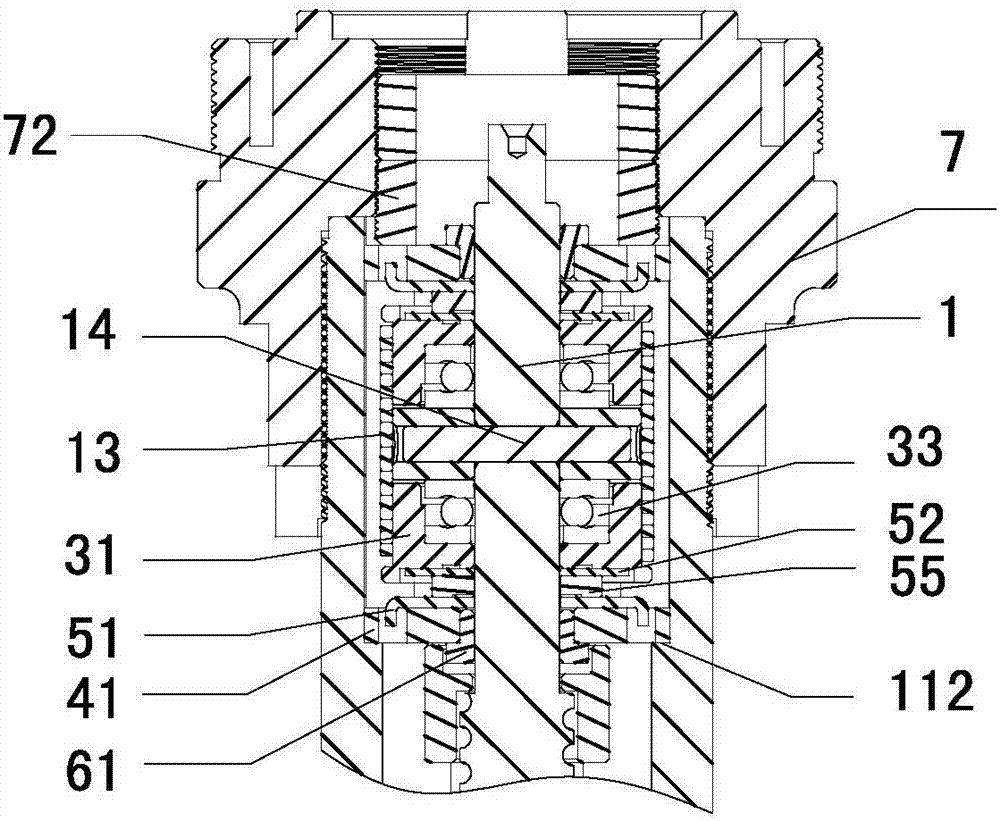

[0030] Such as Figure 1 to Figure 4 As shown, this embodiment shows a two-way self-locking electric push rod. This embodiment is mainly used in solar thermal power generation technology to drive heliostats. Of course, it can also be used for other pairs of two-way self-locking. In the field where the precision of the electric push rod is high, the main structure of the two-way self-locking electric push rod in this embodiment includes a motor, the motor is connected to a drive screw 1, and the drive screw 1 is connected to a drive nut 2 , the motor is installed in the base, the base is fixedly connected with the outer tube 11, and the drive nut 2 is fixedly connected with the inner tube 21, when the motor drives the drive screw 1 to rotate, the drive nut 2 is opposite to the drive screw 1 move. On the whole, relative movement between the inner tube 21 and the outer tube 11 is achieved, and the outermost end of the inner tube 21 is used to drive the heliostat to rotate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com