The Method of Rapid Load Reduction of Unit Generating Sets in Critical Situation

A generator set and load shedding technology, which is applied in the combustion method, combustion control, and fuel supply regulation, etc., can solve the problems of furnace wall collapse, boiler explosion, large fluctuation of fuel, air volume and furnace pressure automatic adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

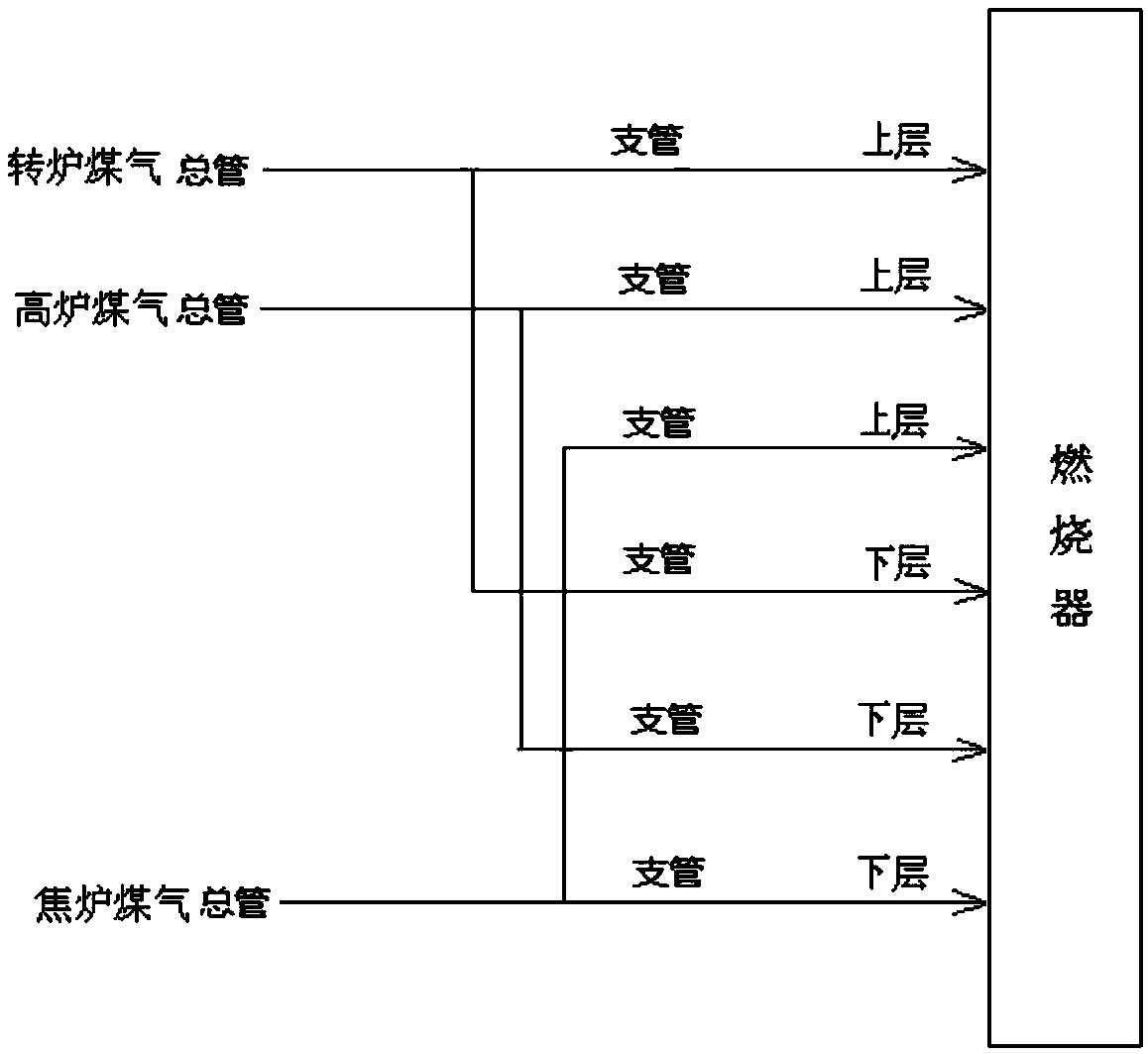

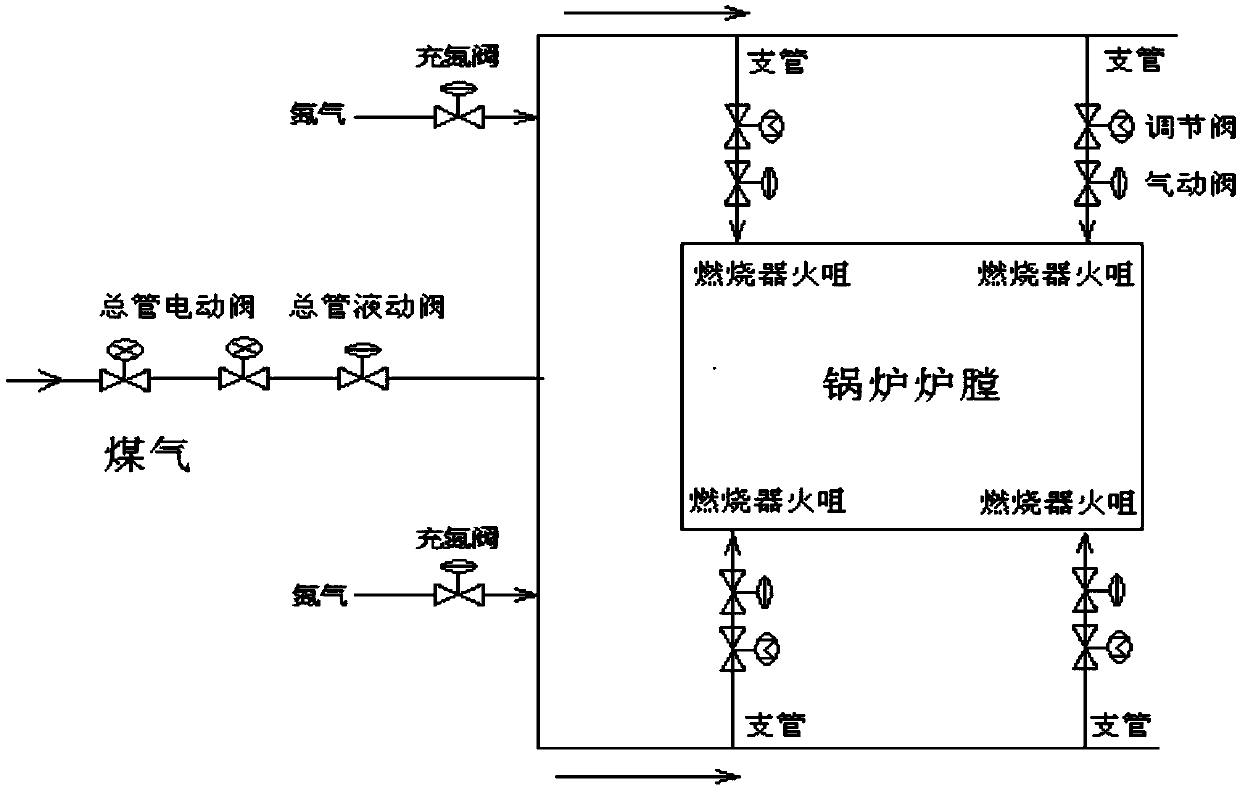

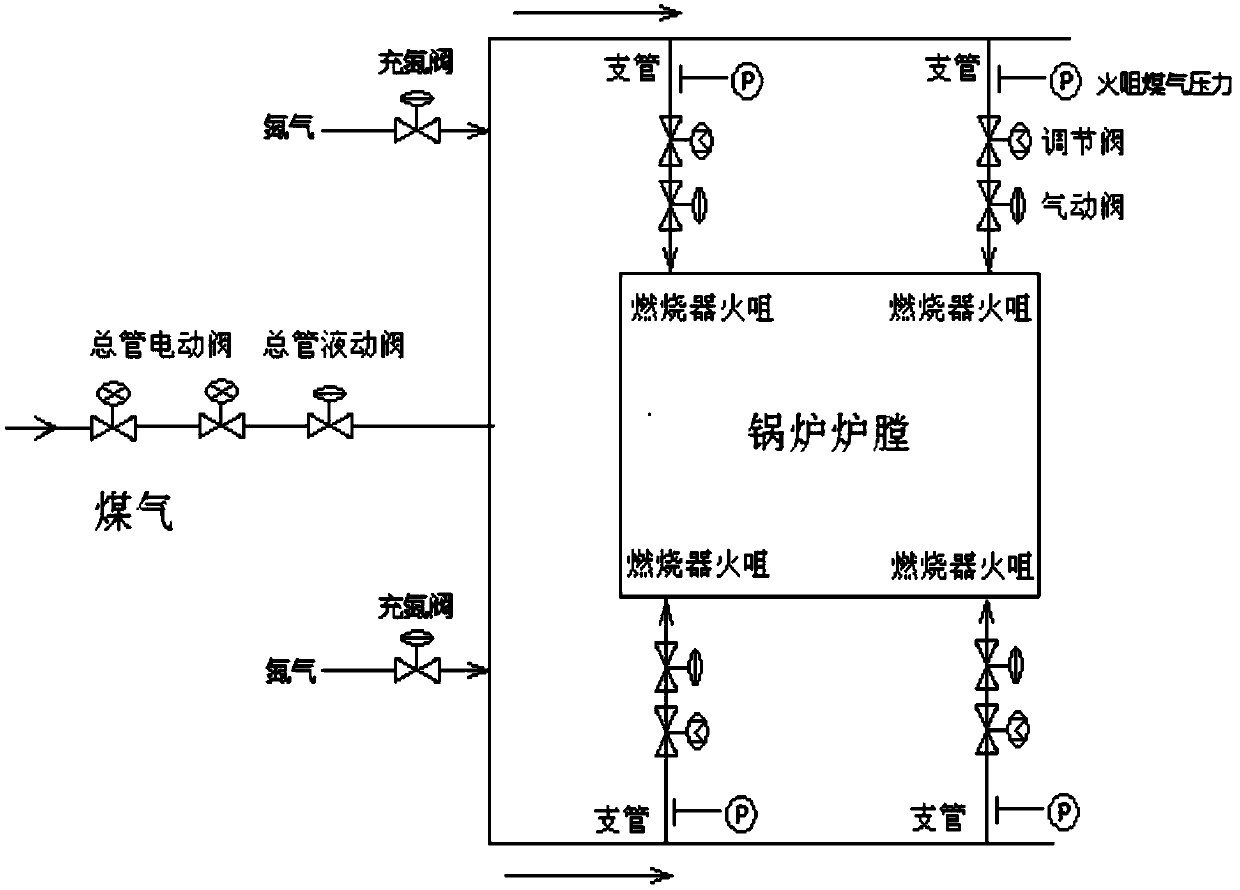

[0021] The present invention aims to propose a method for rapid load reduction of a unitary generator set in critical situations, and realizes safe and stable load reduction control in emergency situations such as a gas boiler with a sharp drop in fuel or failure of main auxiliary equipment, thereby restoring the furnace pressure , air volume, and normal adjustment of turbine speed to avoid major safety accidents.

[0022] In the unit system generator set, the control system that realizes the energy balance between the machine, furnace and electricity is called a coordinated control system, or CCS system for short. When the main auxiliary machine fails, the CCS system calculates the maximum possible output value of the unit according to the switching status of the main auxiliary machine. If the actual load command is greater than the maximum possible output value, a rapid load reduction will occur and the actual load command will be reduced to the maximum. The possible output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com