Anti-slurry-pollution method for spray tower observation window

A technology of observation window and spray tower, which is applied in the field of anti-slurry pollution of spray tower observation window, can solve the problems of complex structure setting, complex structure, inconvenient operation, etc., and achieve clear observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

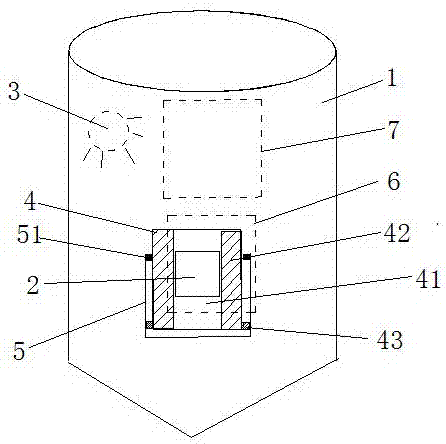

[0039] Such as figure 1 As shown, a high-temperature observation window for a spray granulator is sealed and fixedly arranged on the spray tower body 1, and the lighting lamp 3 is arranged in the spray tower body and is located above the spray rod.

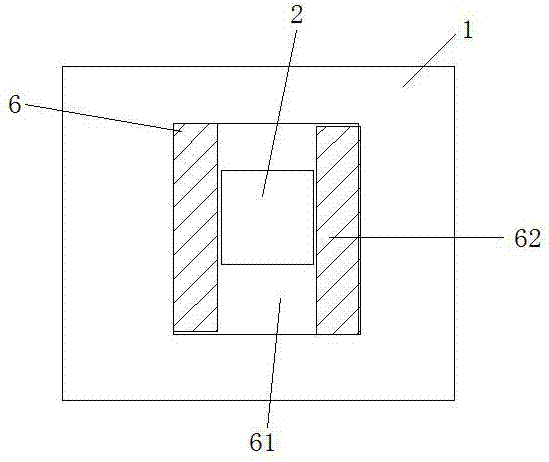

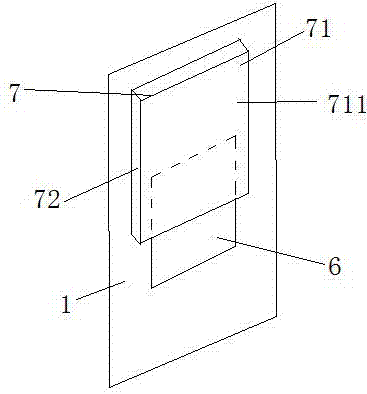

[0040] Such as figure 1 , figure 2 and image 3 As shown, the observation window 2 includes an outer slide plate 4 , an outer block frame 5 , an inner slide plate 6 and an inner slide plate cleaning component 7 .

[0041] The outer baffle frame is U-shaped, and the upper end is open, and the outer baffle frame is arranged on the outer wall surface of the spray tower body on the periphery of the observation window.

[0042] The outer slide plate is located in the outer block frame and can slide up and down along the outer block frame. The outer slide plate includes an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com