Card read-write and transmission system in self-service card receiving machine

A transmission system and card transmission technology, which is applied in the field of card reading and writing and transmission systems, and can solve the problems of slow card transmission, complex structure, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

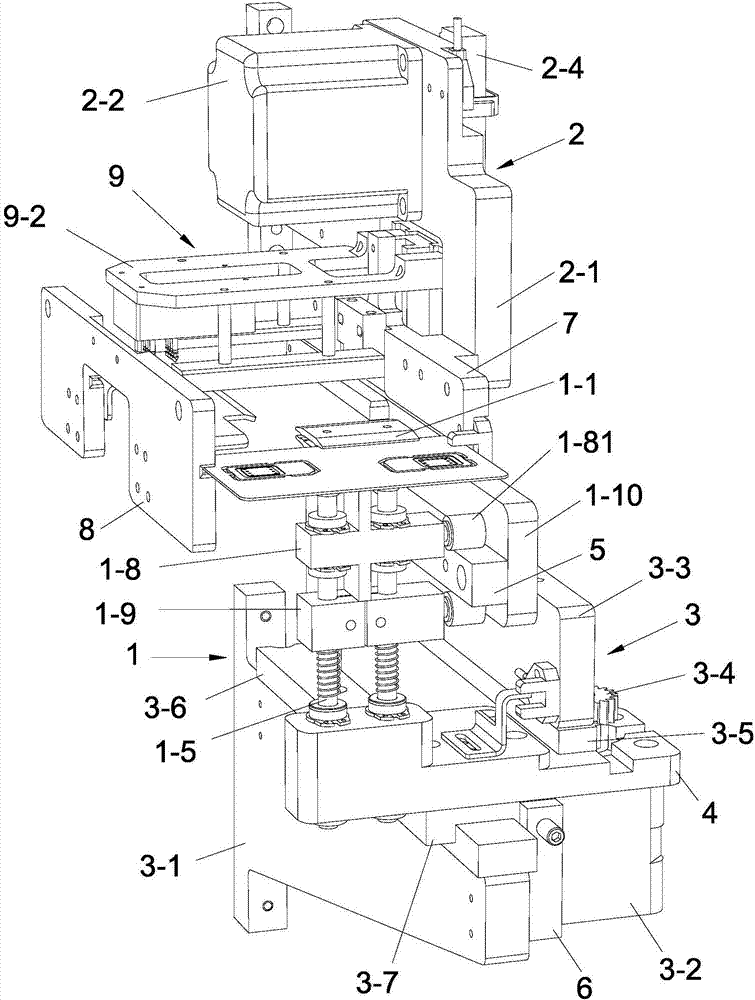

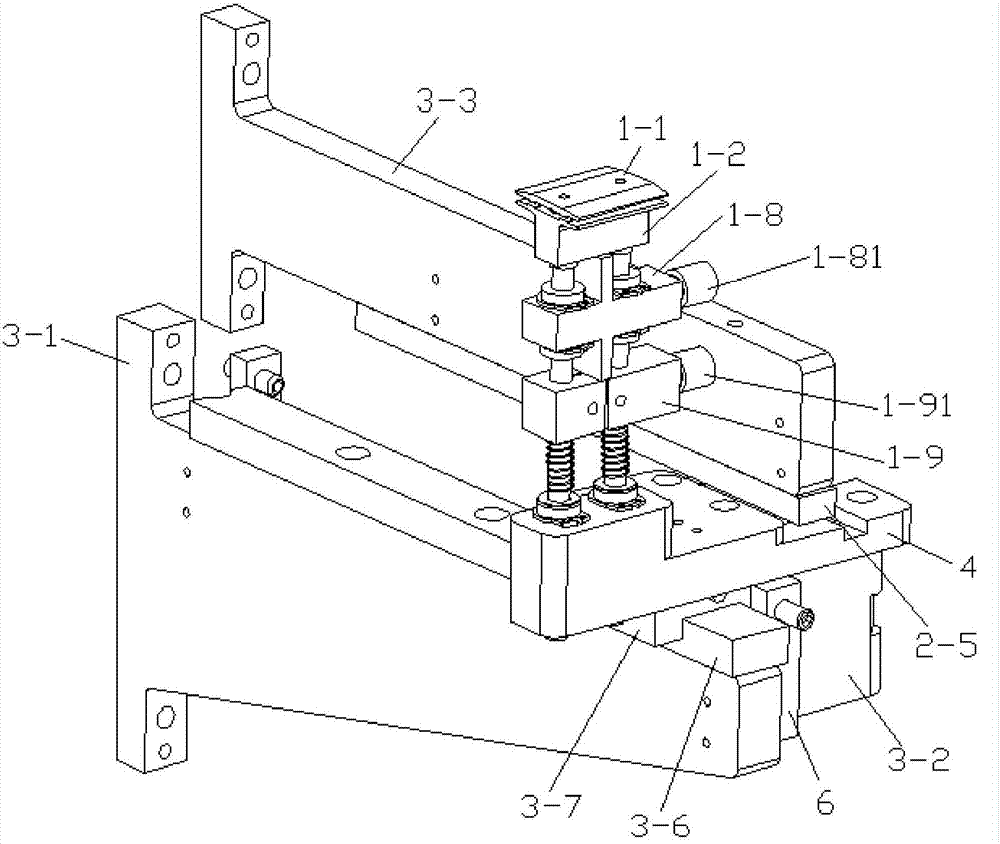

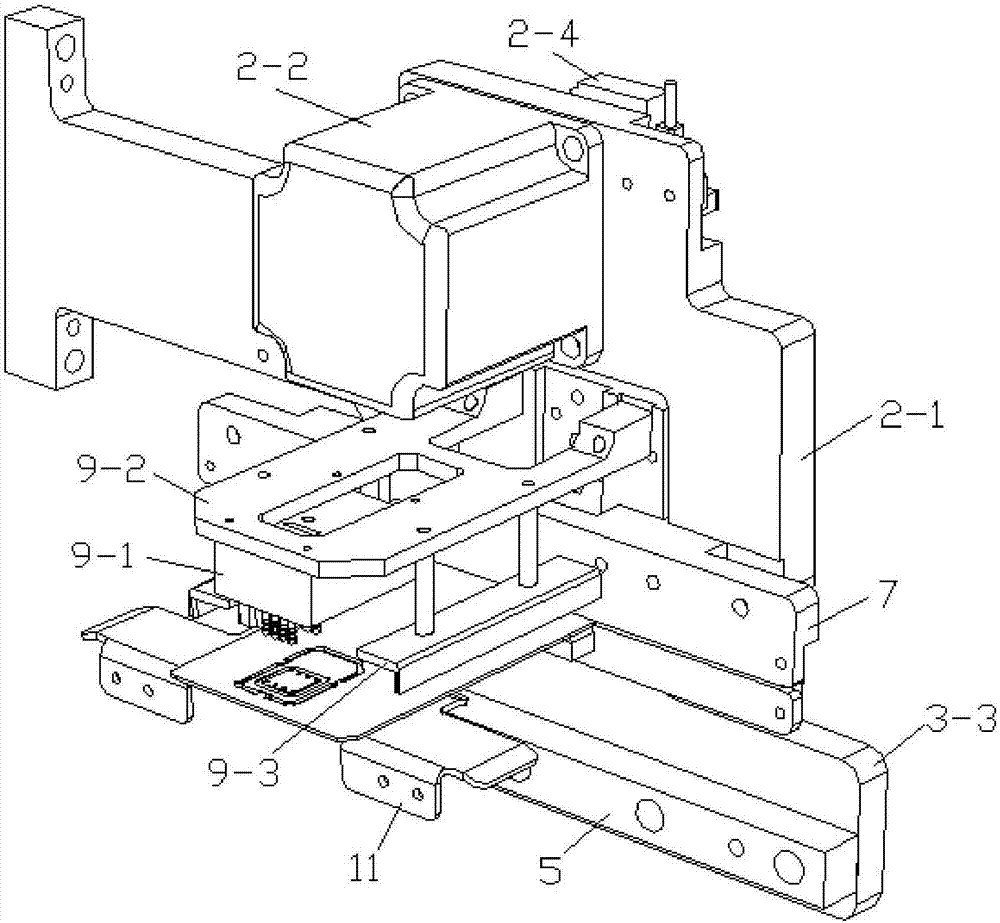

[0044] see Figure 1-6 , the card reading and writing and transmission system in the self-service card receiving machine in the present embodiment includes a card feeding mechanism and a card reading mechanism 9; slot, and a driving mechanism for driving the clamping mechanism 1 to move;

[0045] The clamping mechanism 1 includes a clamping assembly and a clamping drive mechanism that drives the clamping assembly to clamp or loosen the card; the clamping assembly includes an upper clamping part 1-1 and a lower clamping part 1-2 , the upper clamping part 1-1 and the lower clamping part 1-2 are respectively provided with a first clamping part 1-3 and a second clamping part 1-4 at both ends of the extending direction of the card conveying channel, wherein, The first clamping part 1-3 faces the card storage mechanism, and the second clamping part 1-4 faces the card receiving port;

[0046] The drive mechanism includes a horizontal drive mechanism 3 that drives the clamping mecha...

Embodiment 2

[0075] see Figure 7 , The difference between this embodiment and Embodiment 1 is that in this embodiment, the clamping drive mechanism includes a clamping shaft 1-5, a cylinder 1-12, and an external clamping shaft 1-5. The fixed sleeve 1-11, the upper end of the clamping shaft 1-5 is fixedly connected to the upper clamping member 1-1, the lower end is fixed on the cylinder 1-12, and the fixed sleeve 1-11 is set on the clamping On the outer side of the shaft 1-5, the upper end of the fixed sleeve 1-11 acts on the lower clamping part 1-2, and the lower end acts on the cylinder 1-12; a fixed connection block 4 is provided below the cylinder 1-12 One end of the fixed connection block 4 is connected with the transverse drive mechanism 3, and the other end is fixedly connected with the cylinder 1-12. The working principle of the above-mentioned clamping drive mechanism is: when the card needs to be clamped, the cylinder 1-12 drives the clamping shaft 1-5 to move downward, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com