System and method for optimizing grouping and queuing of purchased vehicles

A vehicle marshalling and vehicle technology, which is applied in the system field of optimizing the marshalling and queuing of purchasing vehicles, can solve the problems of affecting the production and feeding rhythm, disorderly parking on the road, low safety factor, etc. The effect of releasing and strengthening control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with the accompanying drawings, the present invention will be further described through the embodiments.

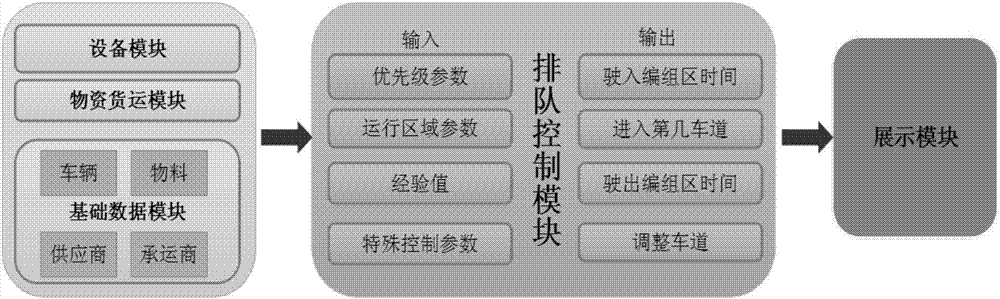

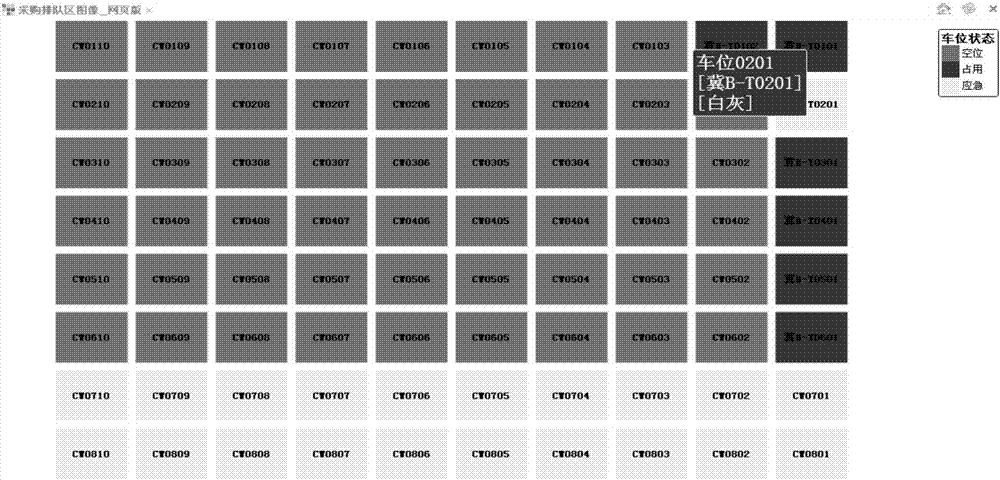

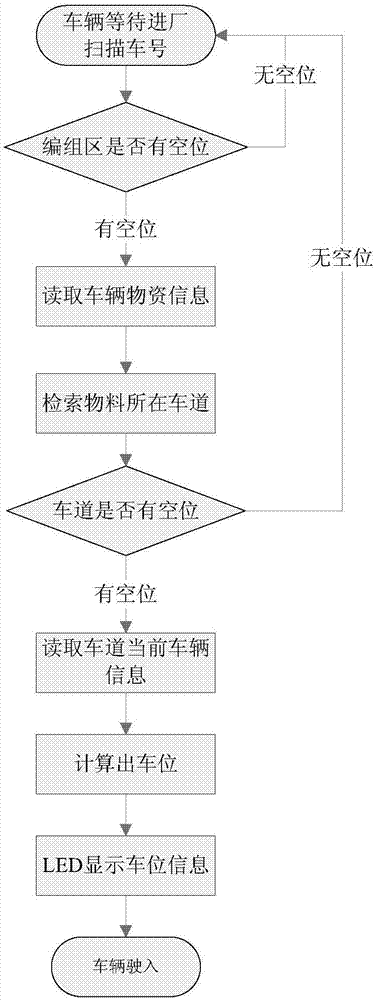

[0046] A system for optimizing the formation and queuing of procurement vehicles, including a basic data module, a material freight module, an equipment module, a queuing control module, and a display module. Interaction, the queuing control module and the display module rely on the network and database to connect and interact with each other; figure 1 A schematic diagram of the system architecture is shown. The basic data module contains the required vehicle information, material information, supplier information, and carrier information. The material freight module records the running track, original weight, and vehicle status of the materials loaded on the vehicle from the starting point (supplier) to the end point (factory gate). , Estimated time of arrival at the factory, the equipment module is responsible for the management of scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com