Reinforced special-shaped cross skeleton

A cross skeleton, reinforced technology, applied in the direction of conductors, insulated cables, electrical components, etc., can solve the problems of poor transmission performance of network cables, poor mechanical properties of skeletons, and affecting the stability of network cables, so as to ensure mechanical and transmission performance, The effect of reducing near-end crosstalk and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

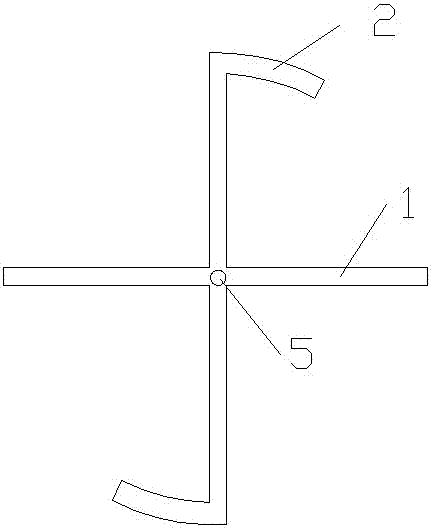

[0025] A reinforced special-shaped cross skeleton, which is composed of two skeleton substrates 1 vertically interspersed with each other, along the length direction of the skeleton substrate 1, a strip-shaped reinforcement 5 is arranged in the overlapped part of the two skeleton substrates 1, said The reinforcing member 5 is composed of metal wire or polymer fiber wire; the upper and lower ends of one of the skeleton substrates 1 are respectively provided with a reinforcing sheet 2, and the reinforcing sheet 2 at the upper end is extended from the upper end of the skeleton substrate 1 to one side. , the reinforcement sheet 2 at the lower end extends from the lower end of the skeleton substrate 1 to the other side.

[0026] Two skeleton substrates 1 are vertically interspersed to form skeleton grooves, and four sets of network cables are respectively placed in the four skeleton grooves. The reinforcing member 5 is set to strengthen the mechanical properties of the skeleton, th...

Embodiment 2

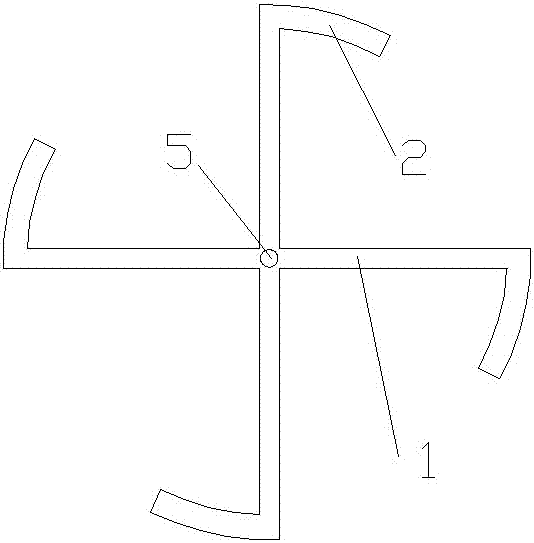

[0029] A reinforced special-shaped cross skeleton, which is composed of two skeleton substrates 1 vertically interspersed with each other, along the length direction of the skeleton substrate 1, a strip-shaped reinforcement 5 is arranged in the overlapped part of the two skeleton substrates 1, said The reinforcing member 5 is composed of metal wire or polymer fiber wire; the upper and lower ends of one of the skeleton substrates 1 are respectively provided with a reinforcing sheet 2, and the reinforcing sheet 2 at the upper end is extended from the upper end of the skeleton substrate 1 to one side. , the reinforcement sheet 2 at the lower end extends from the lower end of the skeleton substrate 1 to the other side. The left and right ends of the other frame substrate 1 are also respectively provided with reinforcement sheets 2, taking the section of the reinforced special-shaped cross frame, the four reinforcement sheets 2 are all along the clockwise direction at both ends of t...

Embodiment 3

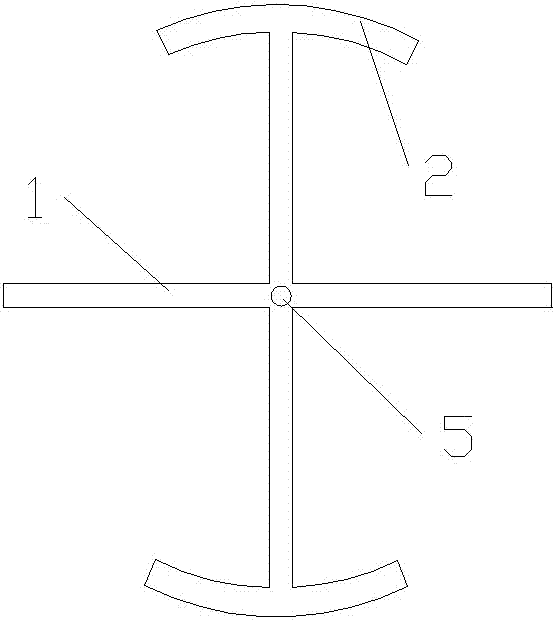

[0033] A reinforced special-shaped cross skeleton, which is composed of two skeleton substrates 1 vertically interspersed with each other, along the length direction of the skeleton substrate 1, a strip-shaped reinforcement 5 is arranged in the overlapped part of the two skeleton substrates 1, said The reinforcement 5 is composed of metal wire or polymer fiber wire; the upper and lower ends of one of the skeleton substrates 1 are respectively provided with a reinforcement sheet 2, and the reinforcement sheet 2 at the upper end is extended from the upper end of the skeleton substrate 1 to both sides. , the reinforcement sheet 2 at the lower end extends from the lower end of the skeleton substrate 1 to both sides.

[0034] Two skeleton substrates 1 are vertically interspersed to form skeleton grooves, and four sets of network cables are respectively placed in the four skeleton grooves. The reinforcing member 5 is set to strengthen the mechanical properties of the skeleton, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com