Lightning-proof strain composite insulator

A composite insulator and tensile technology, applied in suspension/strain insulators and other directions, can solve the problem of less research on the umbrella shape of tensile composite insulators, and achieve the effects of low operation and maintenance cost, safe and convenient use, and effective update.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

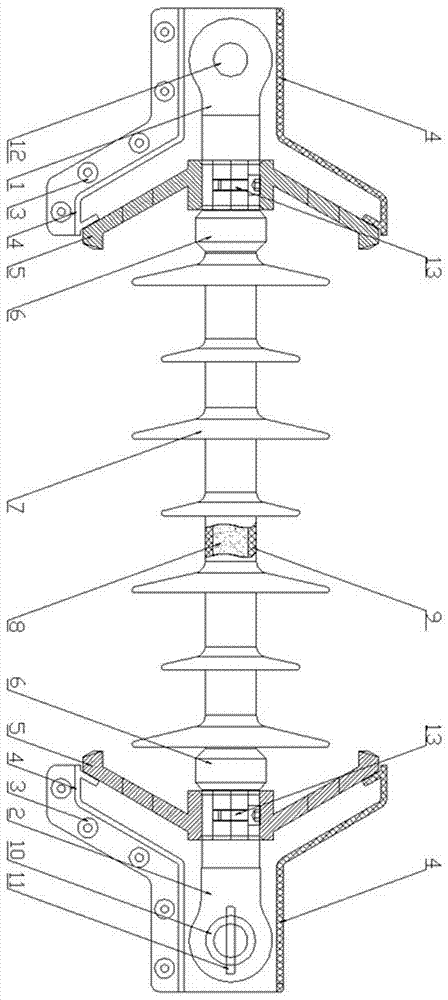

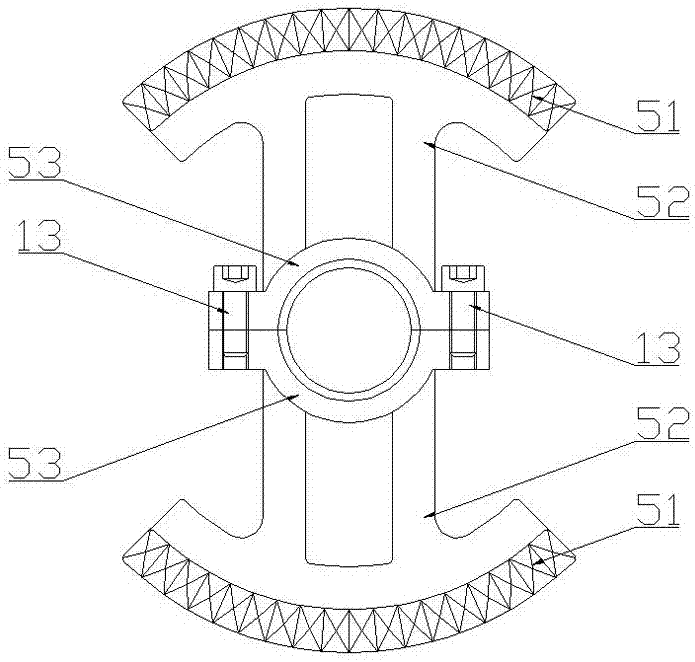

[0013] Embodiment: A lightning-proof and strain-resistant composite insulator, including: connecting fittings A1, connecting fittings B2, button holes 3, insulating shields 4, isolated rings 5, sealing ports 6, silicone umbrella skirts 7, insulating mandrels 8, Silicone sleeve 9; the outer side of the insulating mandrel 8 is provided with a silicone sleeve 9, and the outside of the silicone sleeve 9 is arranged in pairs with silicone umbrella skirts 7; the two sides of the insulating mandrel 8 are respectively provided with sealing ports 6, and the sealing ports 6 at both ends The outer side is provided with an isolated ring 5 and fixed by screws 13; the outer sides of the isolated rings 5 at both ends are respectively provided with connecting fittings A1 and connecting fittings B2, and connecting fittings A1 and connecting fittings B2 are respectively provided with connecting pin holes 12; the connecting fittings The connecting pin holes 12 on B2 are provided with connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com