Machining device for advanced small guide pipe for underground space and hydraulic tunnel

A technology of advanced small conduit and underground space, which is applied in the field of advanced small conduit processing device, can solve the problems of long time consumption, large axial reaction force, damage to internal threads, etc., and achieves increased drilling efficiency, reliable and durable travel, and heating efficiency. multiplier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

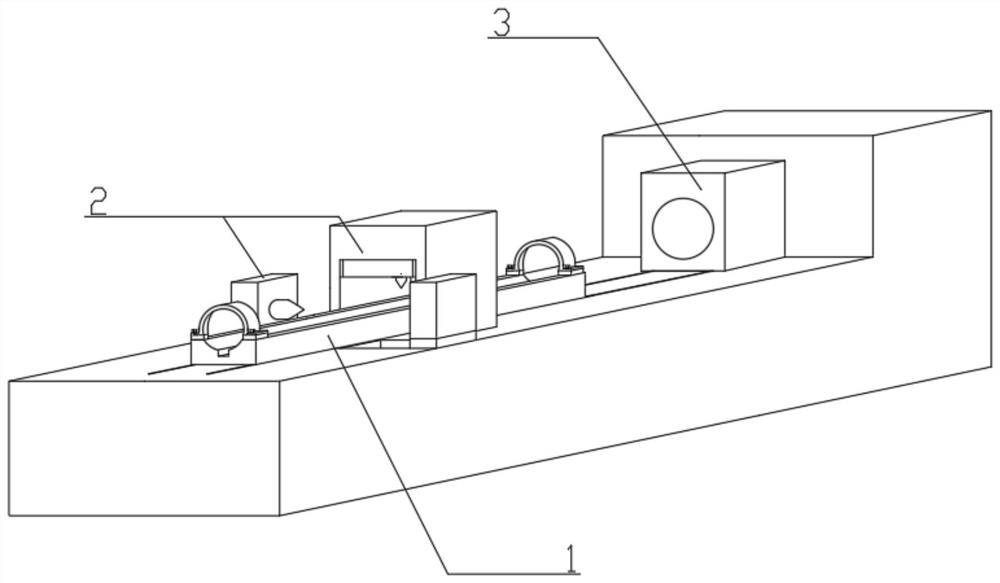

[0019] Embodiment 1: The front small catheter processing device is characterized in that the device includes a frame, a moving fixture 1, a grouting hole processing assembly 2 and a heating assembly 3, wherein:

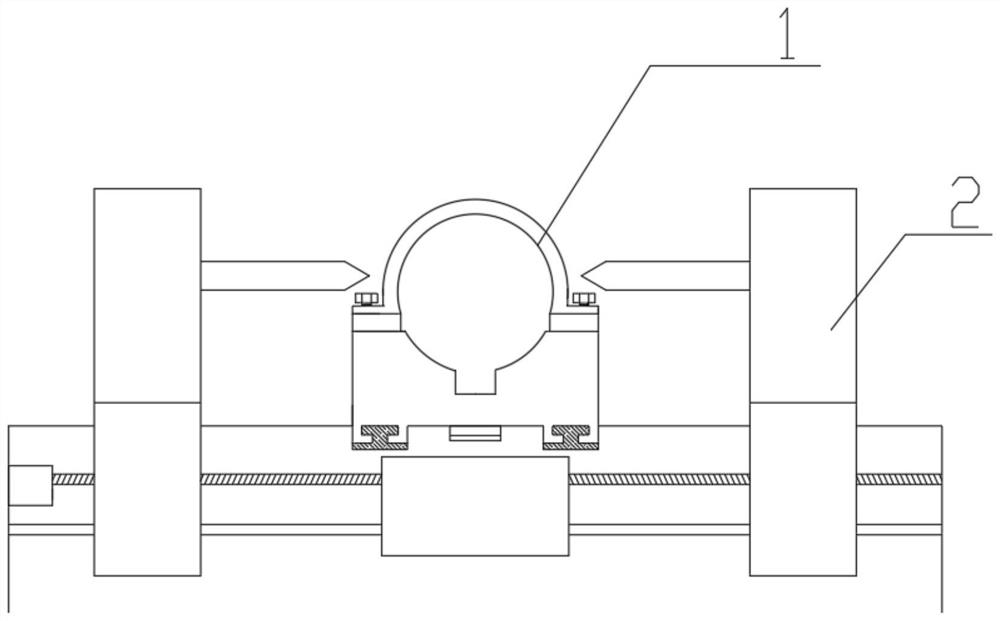

[0020] An arc-shaped groove is arranged on the upper surface of the mobile fixture 1, the arc of the arc-shaped groove corresponds to the circumference of the small catheter, and a rectangular groove is arranged at the bottom of the arc-shaped groove, and the arc-shaped groove and the rectangular groove are connected; the mobile fixture 1 on the left and right sides of the arc-shaped groove is provided with hoops , the hoop is connected with the moving fixture 1 through bolts; the lower end surface of the moving fixture 1 is provided with a chute along the front and rear direction, and a slide rail matching the chute is fixed on the frame; the lower end surface of the moving fixture 1 is also provided with teeth along the front and rear direction. The rack is fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com