Wheel bearing cap and wheel bearing

A technology of wheel bearing and wheel speed, applied in the field of wheel bearing, can solve the problems of firm connection, heavy weight, etc., and achieve the effect of reducing the tolerance chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

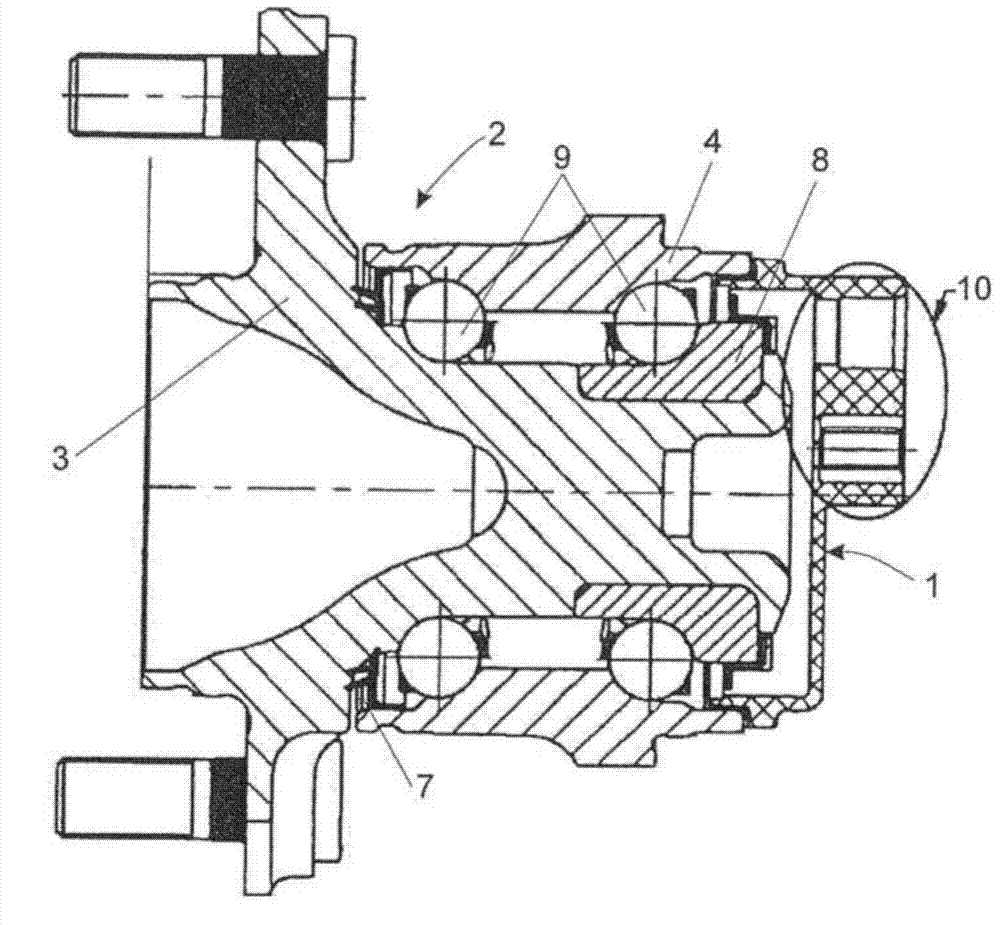

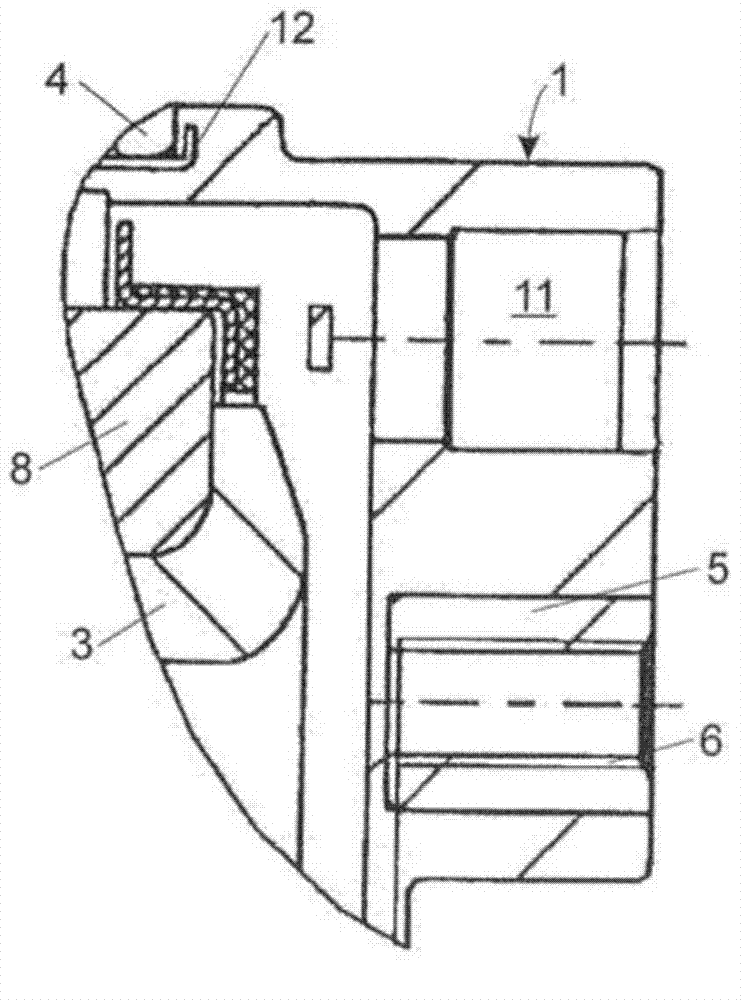

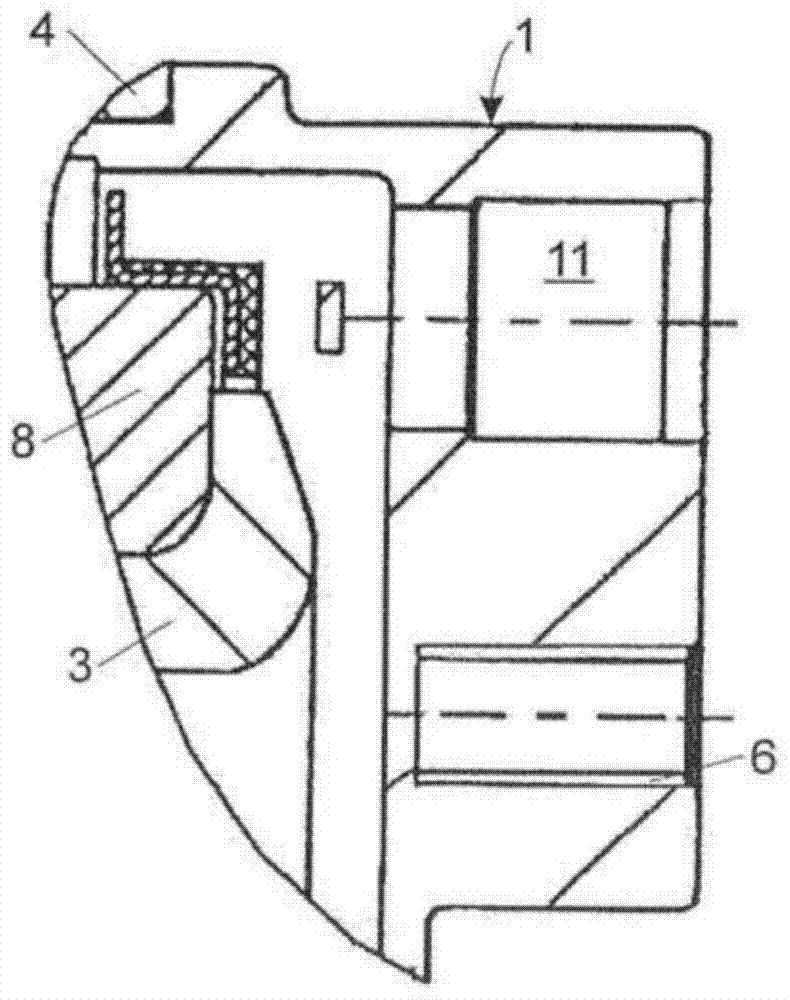

[0024] FIG. 1 shows a wheel bearing 2 of a vehicle, not shown, onto which a wheel bearing cap 1 is fitted. The wheel bearing cap 1 is constructed according to the prior art and is made of thermoplastic.

[0025] The wheel bearing 2 includes a flange inner ring 3 , which forms a slanted ball bearing 9 with a flange outer ring 4 arranged on a circumferential side and a bearing inner ring 8 . FIG. 2 shows a detail view of a section 10 of the wheel bearing cap 1 from FIG. 1 .

[0026] The inclined ball bearing 9 here comprises two rows of balls and a cage arranged between them. The bearing inner ring 8 is arranged on the circumference of the flange inner ring 3 and is surrounded by one of the two rows of balls.

[0027] Another row of balls surrounds the flange inner ring 3 and two rows of balls are surrounded by the flange outer ring 4 on the outside. A sealing element 7 is arranged in addition to the flange outer ring 4 and the flange inner ring 3 .

[0028] Holes for screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com