A fault-tolerant control method for maximum torque-current ratio mtpa of five-phase permanent magnet motor considering reluctance torque

A technology of maximum torque current and permanent magnet motors, which is applied in motor control, motor generator control, electronic commutation motor control, etc., and can solve the problems of not fully utilizing the output torque performance of embedded permanent magnet motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

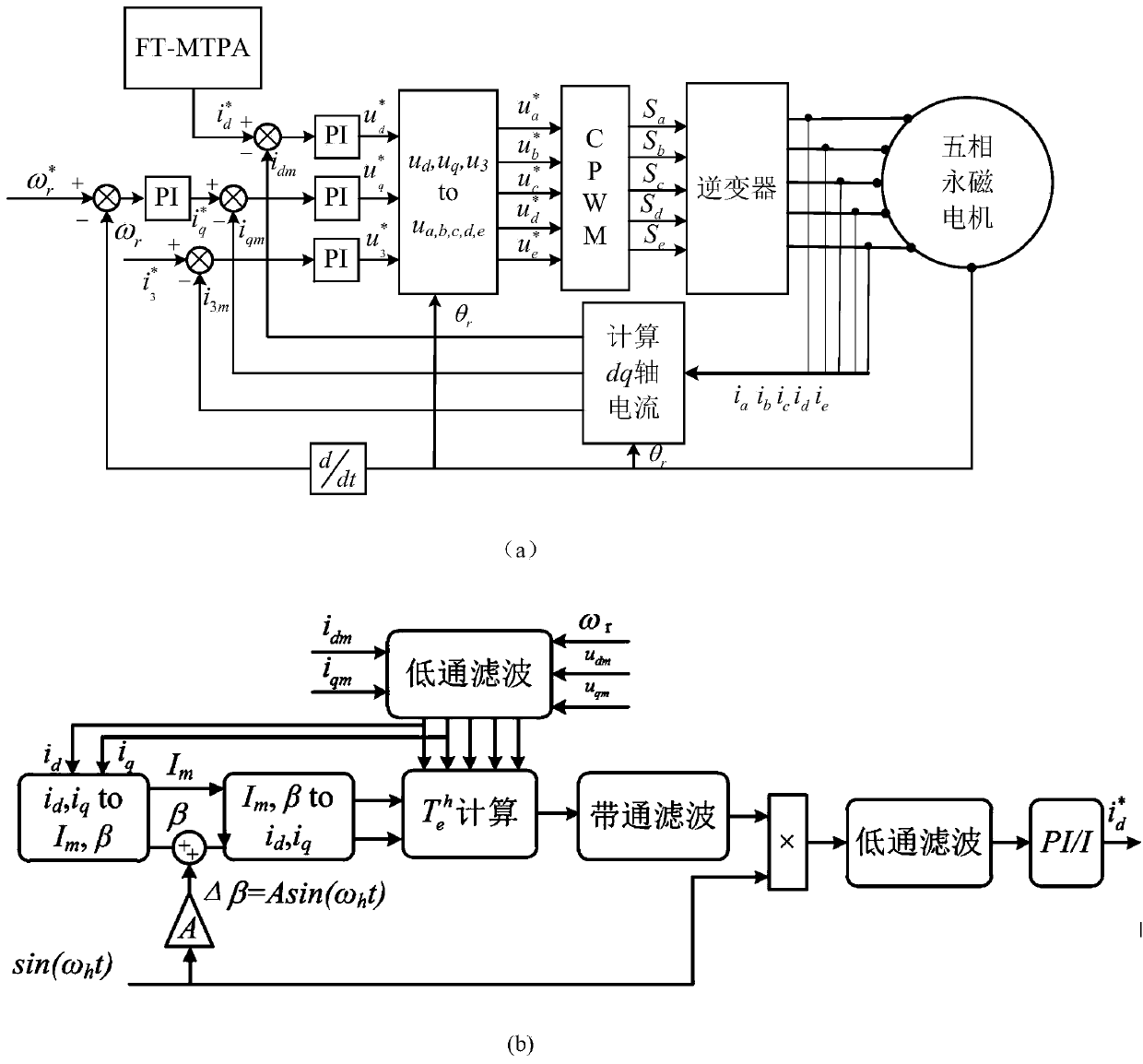

[0056] Specific embodiment 1 mainly introduces the maximum torque-to-current ratio fault-tolerant control realized based on virtual signal injection and reduced-order matrix, and its control block diagram is as follows figure 1 shown. The specific implementation manner and implementation effect of this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0057] Step 1, detect the speed of the five-phase permanent magnet motor as the speed feedback of the motor ω r , the given speed ω * r and feedback speed ω r Do the difference to get the speed error e of the motor r , using PI controller according to the speed error e r Calculate the q-axis current of the five-phase permanent magnet motor, and the output of the PI controller is the given q-axis current i * q .

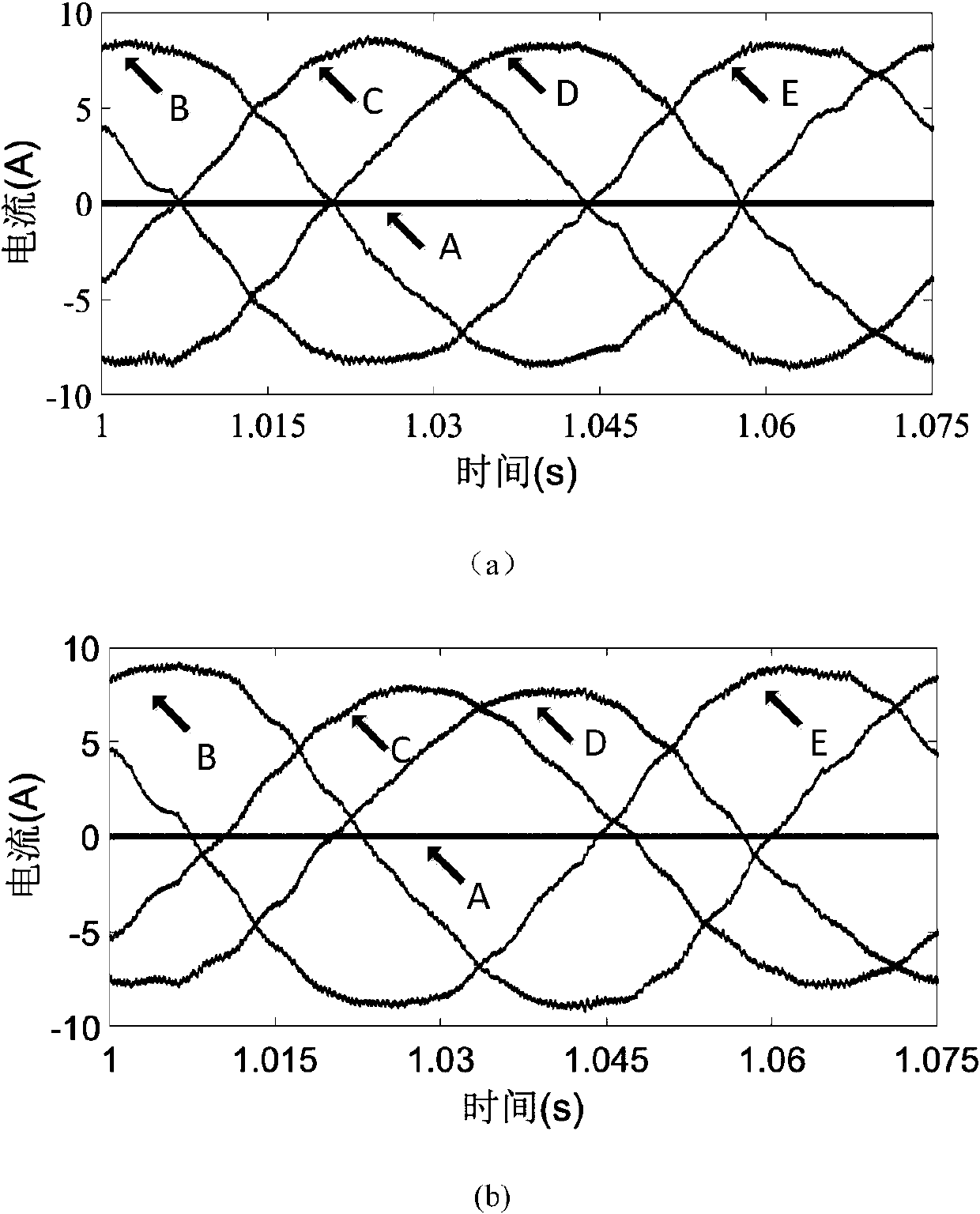

[0058] Step 2, use the current sensor to sample the current i of each phase of the five-phase permanent magnet motor a , i b , i c , i d , i e , to determine the f...

specific Embodiment 2

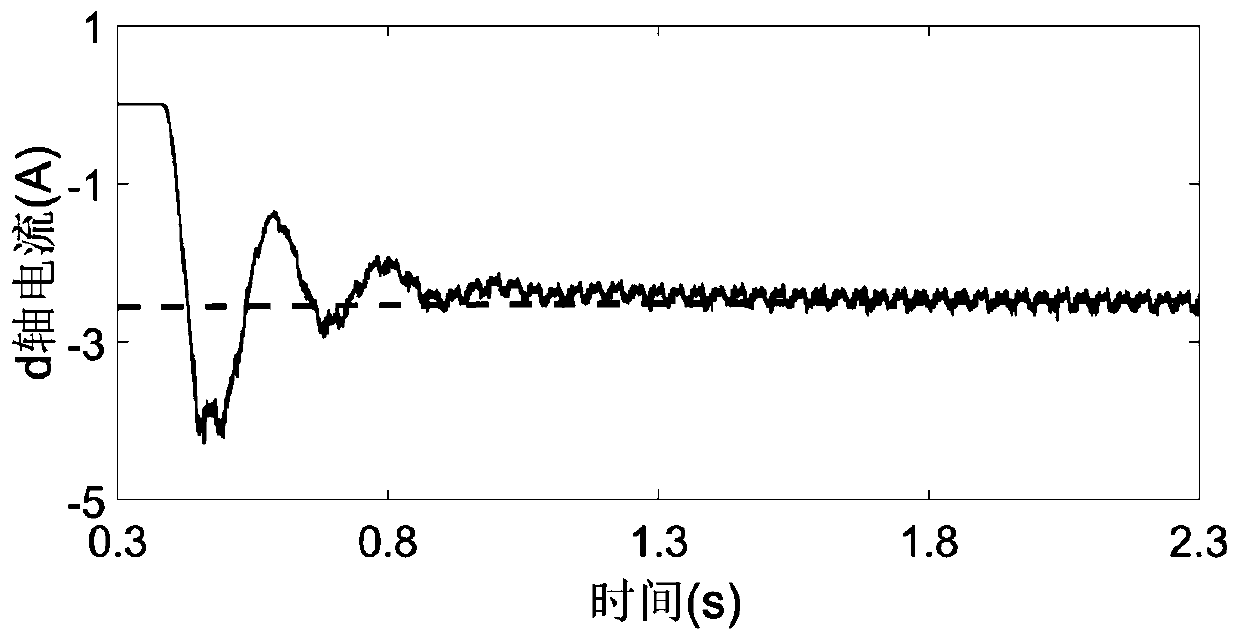

[0097] The specific embodiment 2 mainly introduces the maximum torque current ratio fault-tolerant control based on high-frequency signal injection and reduced-order matrix, and its control block diagram is as follows figure 2 shown. Compared with the specific embodiment 1, the FT-MTPA algorithm of the specific embodiment 2 adopts the method of high-frequency signal injection, and the high-frequency signal injection does not need the specific parameters of the motor compared with the virtual signal injection, but it will increase the copper of the system. consumption and iron consumption. Attached below Figure 5 and Figure 6 , carefully explain the specific implementation of this embodiment.

[0098] Step 1, detect the speed of the five-phase permanent magnet motor as the speed feedback of the motor ω r , the given speed ω * r and feedback speed ω r Do the difference to get the speed error e of the motor r , using PI controller according to the speed error e r Calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com