A fault-tolerant control method for maximum torque-current ratio of five-phase permanent magnet motor based on svpwm

A technology of maximum torque current and permanent magnet motor, which is applied in motor control, motor generator control, electronic commutation motor control, etc. Embedded permanent magnet motors have the advantages of wide speed regulation range and other problems, to achieve the effect of improving fault-tolerant operation efficiency, widening the speed regulation range, and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

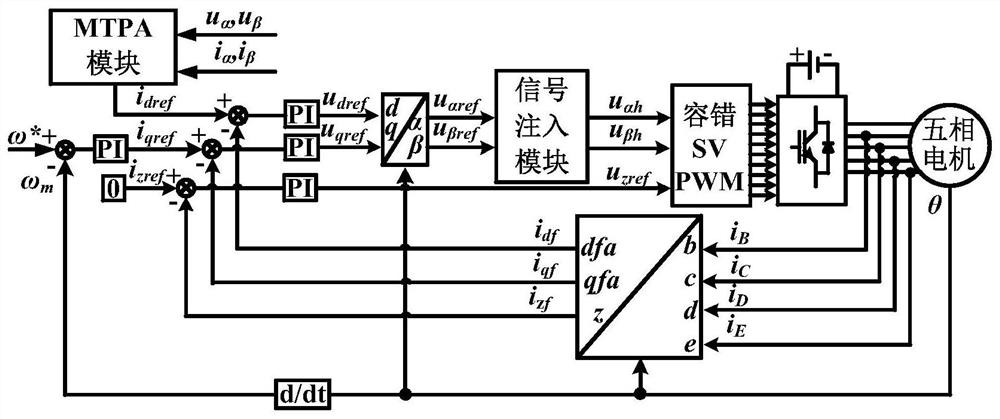

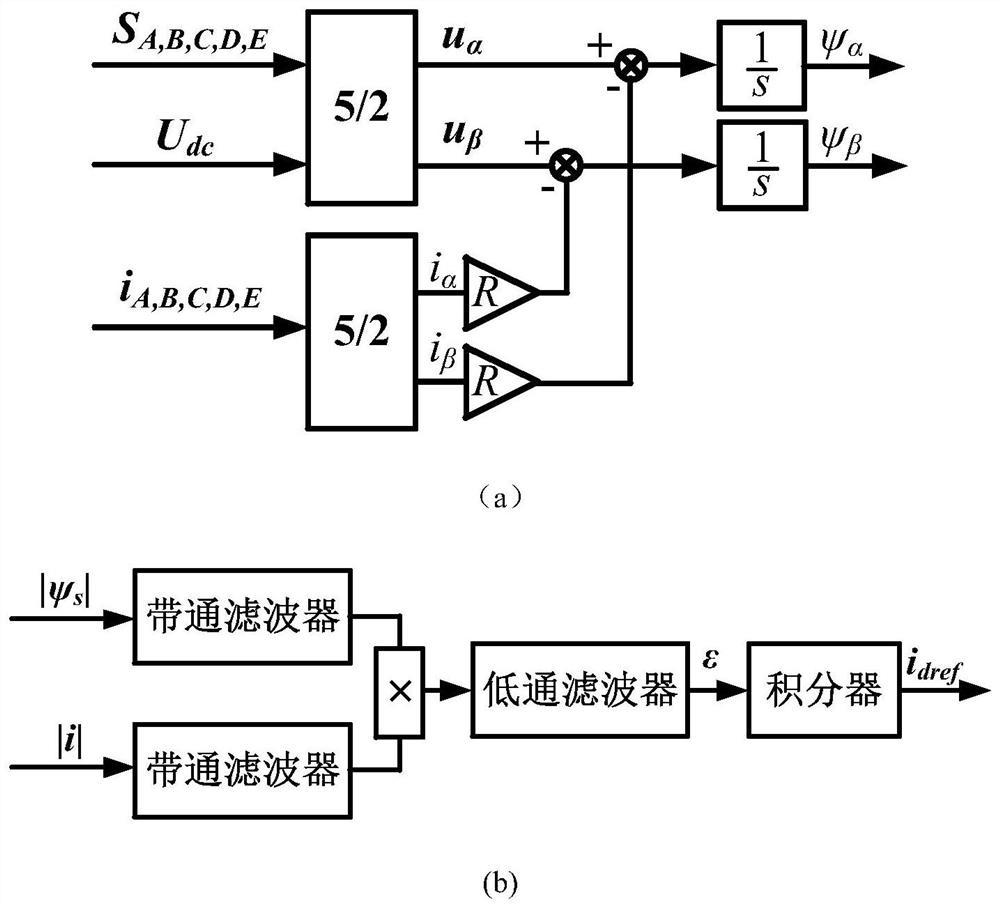

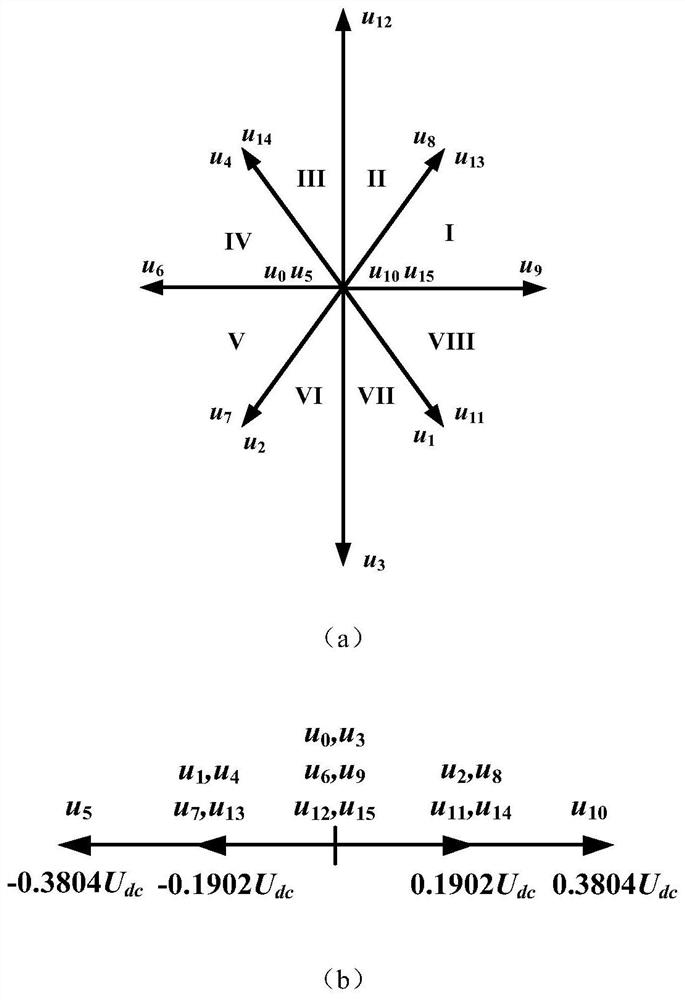

[0091] figure 1 The block diagram of the maximum torque-to-current ratio fault-tolerant control realized by using the space vector signal injection method and fault-tolerant SVPWM is shown. The specific implementation steps of this method are described in detail below in conjunction with the control block diagram:

[0092] Step 1, detect the speed of the five-phase permanent magnet motor as the feedback speed ω of the motor m , the given speed ω * and feedback speed ω m Compared with the speed error e of the motor, the q-axis current of the five-phase permanent magnet motor is calculated by using the PI controller according to the speed error e, and the output of the PI controller is a given q-axis current i qref .

[0093] Step 2, use the current sensor to sample the current i of each phase of the five-phase permanent magnet motor A , i B , i C , i D , i E , according to the phase current obtained by sampling to determine the fault phase of the five-phase permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com