Pan gland for frying beef steak

A frying pan and lidding technology, applied in the field of barbecue utensils, can solve the problems of taste influence, different water content, unevenness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

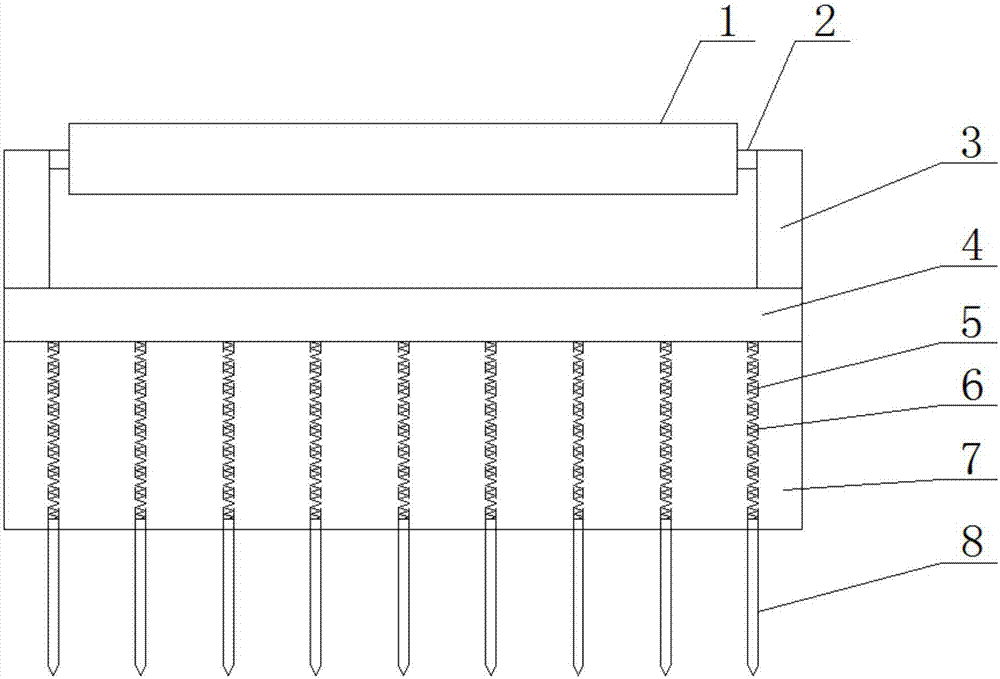

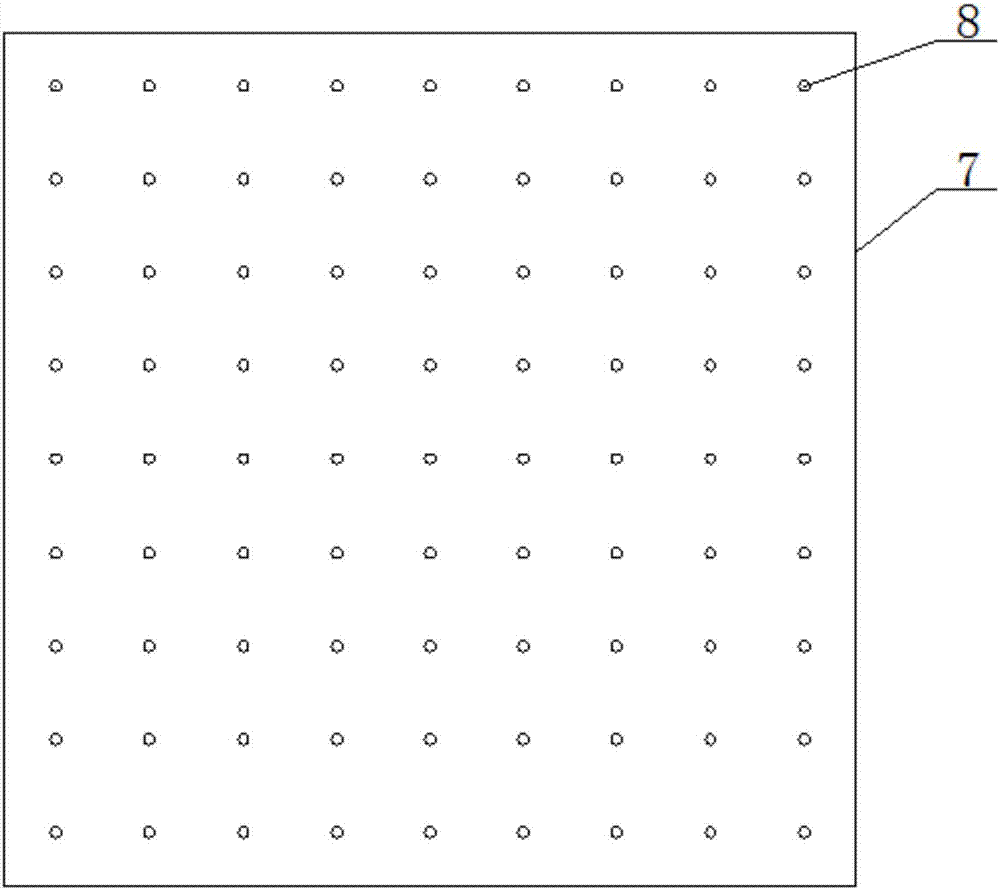

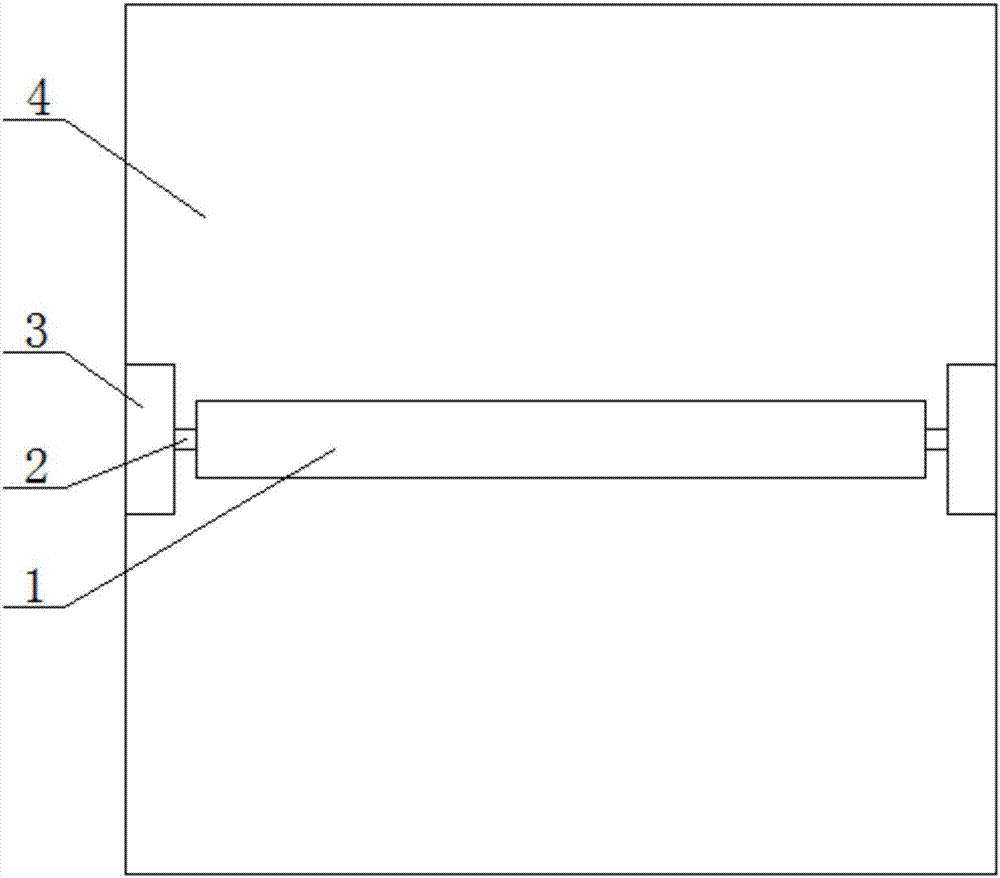

[0012] Such as Figure 1-3 As shown, the grilled steak pan gland described in this specific embodiment includes a handle 1, a handle central shaft 2, a central shaft seat 3, and a spring seat plate 4; the handle 1 is fixedly sleeved on the handle central shaft 2; The two ends of the handle central axis 2 are welded between the central axis seat 3; the central axis seat 3 is welded on both sides of the spring seat plate 4; it also includes a spring 5, a spring limit seat 7, and a steel nail 8; the spring limit The middle part of the seat 7 is evenly provided with a plurality of round holes 6, the number of the round holes 6 is equal to that of the spring 5 and the steel nails 8; the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com