Feeding heating and auxiliary riveting method for riveted shaft

A technology of riveting and feeding device, which is applied in the field of sheet metal parts processing, can solve the problems that the gear box cannot meet the use requirements and the high scrap rate, and achieve the effect of ensuring the riveting precision, improving the production efficiency and production automation, and improving the riveting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

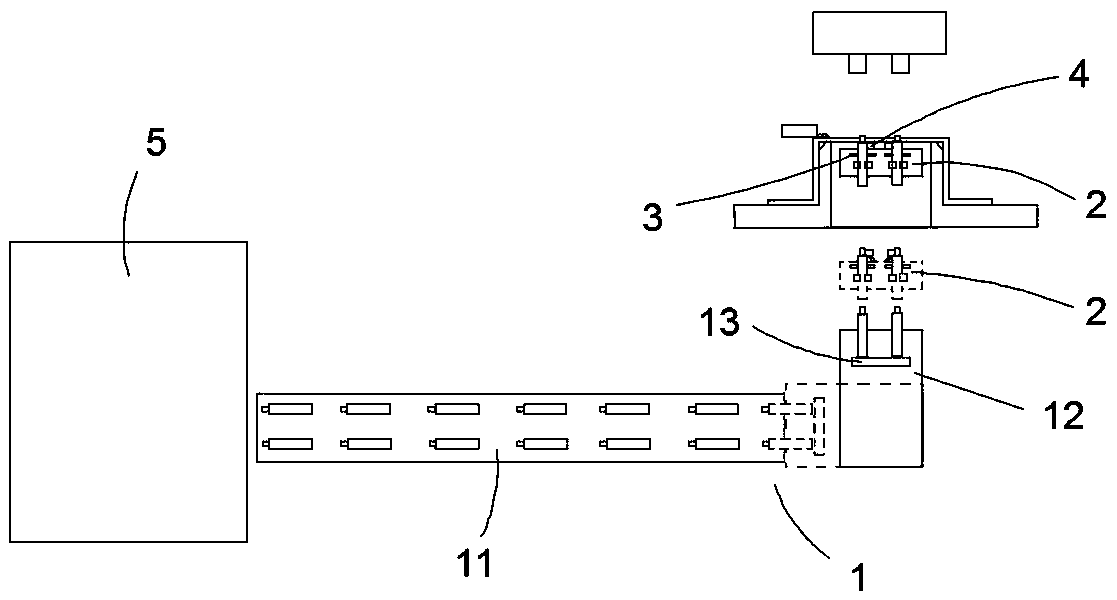

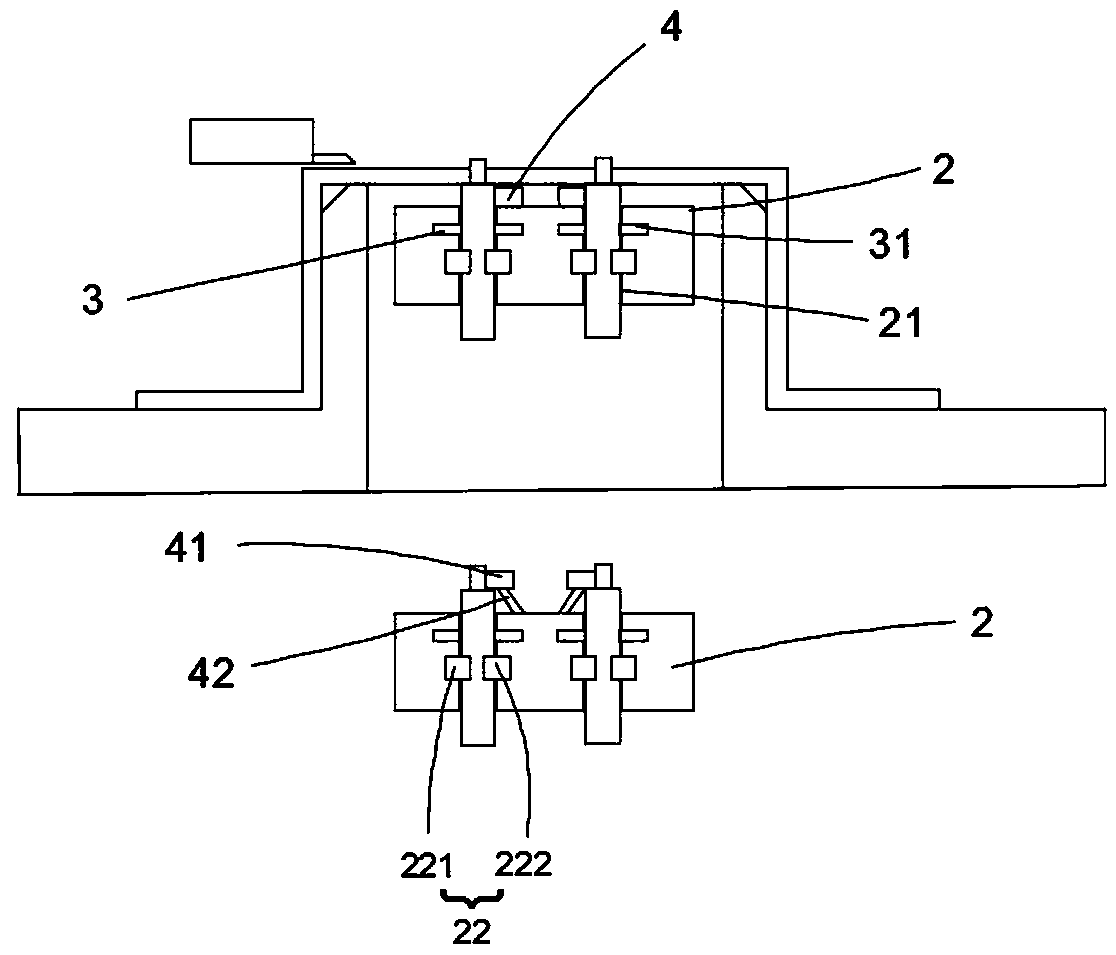

[0024] The invention discloses a riveting shaft feeding heating and auxiliary riveting method, such as Figure 1 to Figure 3 shown, including the following steps:

[0025] a. The grasping manipulator 12 grabs a group of riveting shafts from the material transfer belt 11, and the grasping manipulator 12 rotates to send the riveting shafts to the bottom of the clamping and feeding device 2;

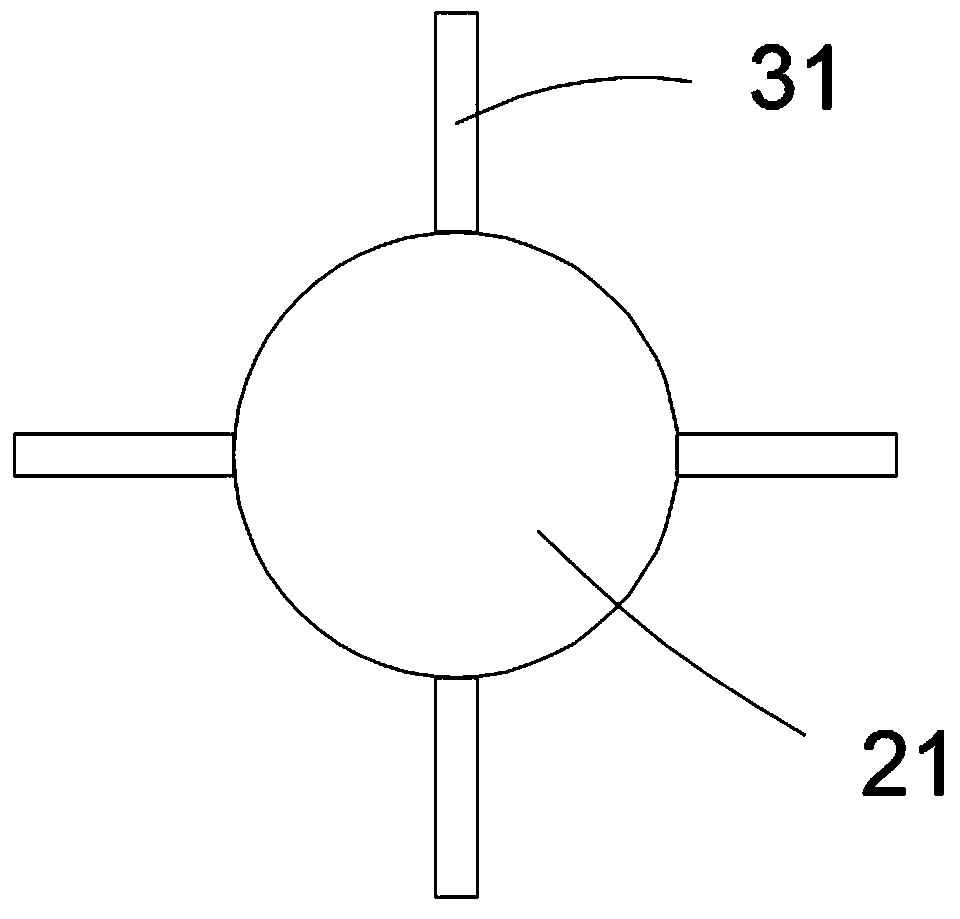

[0026] b. The pusher driving device operates, drives the pusher device 13 to rise, and pushes a group of riveting shafts into a group of shaft placement chambers 21 of the clamping and feeding device 2;

[0027] c. When the riveting shaft reaches the set position, the clamping drive device operates, and the clamping device 22 clamps the riveting shaft; specifically includes: the position detection device in the shaft placement chamber 21 detects the position of the riveting shaft and feeds back to the control module , when the riveting shaft reaches the set position, the control module sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com