Brake disc DTV repairing machine

A brake disc and repairing machine technology, which is applied in the direction of manufacturing tools, grinding drive devices, and grinding machine parts, etc., can solve the problems of narrow use range, large customer complaints, and many parts, and achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

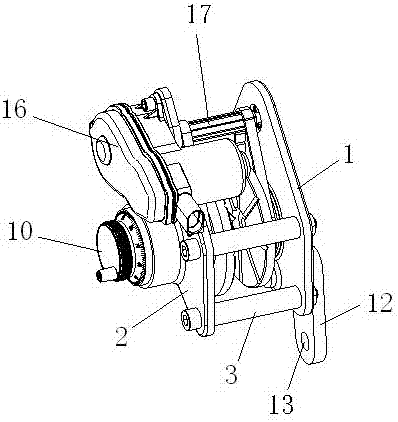

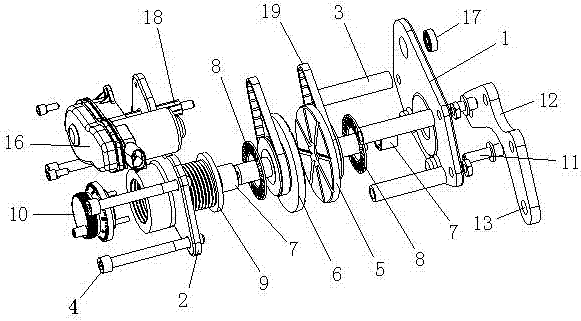

[0030] As shown in the figure, the brake disc DTV repairing machine of this embodiment includes an inner plate 1 and an outer plate 2. The inner plate 1 and the outer plate 2 are provided with three through holes corresponding to the positions. A support sleeve 3 is clamped at the position of the through hole, and they are fixedly connected together by fastening bolts 4 passing through the outer plate 2 , the support sleeve 3 and the inner plate 1 in sequence. A first grinding wheel 5 and a second grinding wheel 6 are installed between the inner plate 1 and the outer plate 2. The inner plate 1 is provided with a limiting hole, and a copper sleeve 7 is installed in the limiting hole. The rotating shaft of the first grinding wheel 5 Extending into the copper sleeve 7, the inner plate 1 is offset against the first grinding wheel 5 through the end face bearing 8, so that the first grinding wheel 5 is flexibly connected with the inner plate 1; the outer plate 2 is provided with a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com