A method for controlling bottomhole flow pressure of a coalbed methane well

A coalbed methane well and bottomhole flowing pressure technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of poor effectiveness, frequent operation, labor-intensive, etc., achieve simple control operation and improve control effectiveness , Facilitate the effect of large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

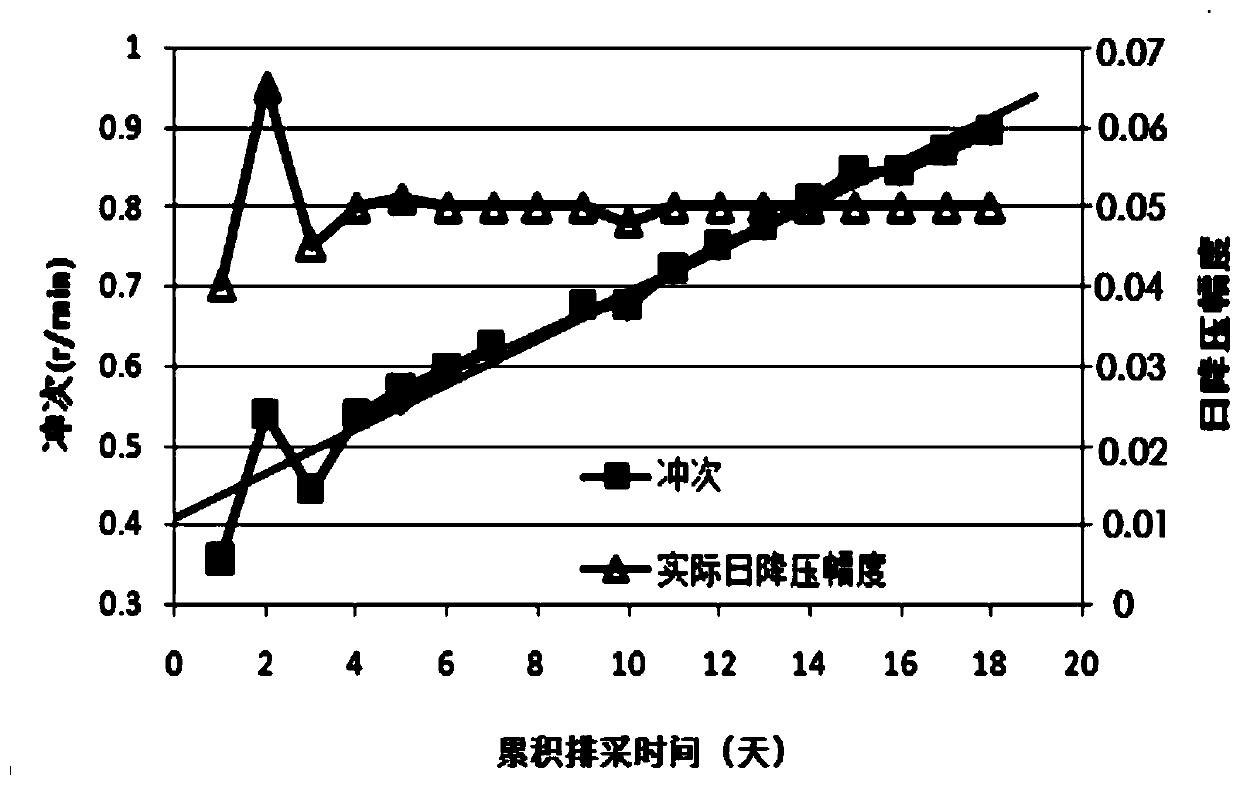

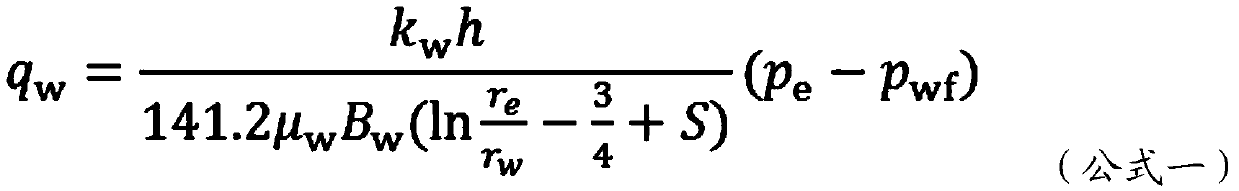

[0109] In this embodiment, the control of the bottomhole flow pressure in the single-phase water flow section of Well X is taken as an example. The well was put into production on January 29, 2016, and the reasonable daily depressurization rate determined was 0.05MPa / d. In order to realize the fine control of bottomhole flow pressure, the method provided by the embodiment of the present invention is used for control:

[0110] Make the pumping unit run at the minimum pumping frequency of 0.2 times / min. After 8 hours, calculate the daily pressure reduction range under the minimum stroke frequency to be 0.01MPa / d. If it is less than the reasonable daily pressure reduction range of 0.05MPa / d, continue to increase pumping The stroke frequency of the oil machine (the increase rate shall not exceed 10% of the previous frequency).

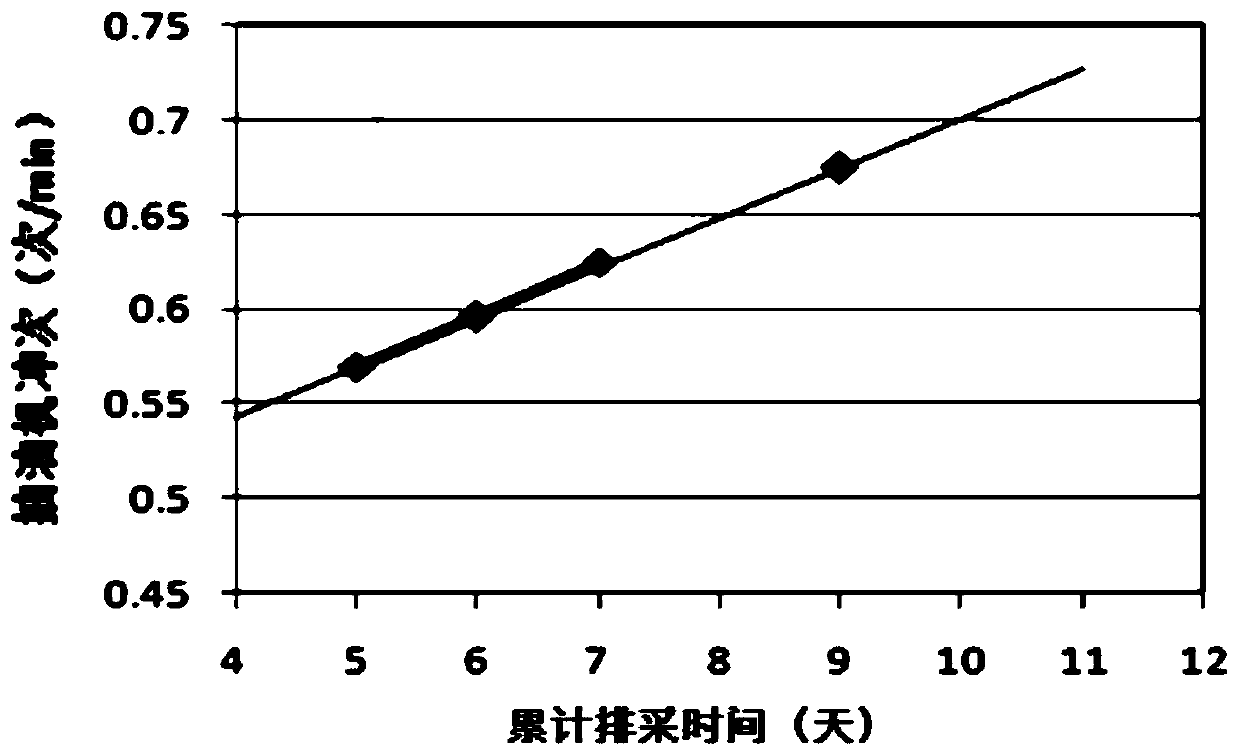

[0111] Repeat the above steps every 8 hours until the first moment when the cumulative drainage time is 5 days. At this time, the actual daily depressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com