A method for controlling the working cycle of a drainage pump of a coalbed methane well

A coalbed methane well and coal seam control technology, which is applied in the directions of drainage, pump control, earthwork drilling, etc., can solve problems such as the useless power of drainage pumps, and achieve the effects of saving energy consumption, stable gas production, and accurate working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

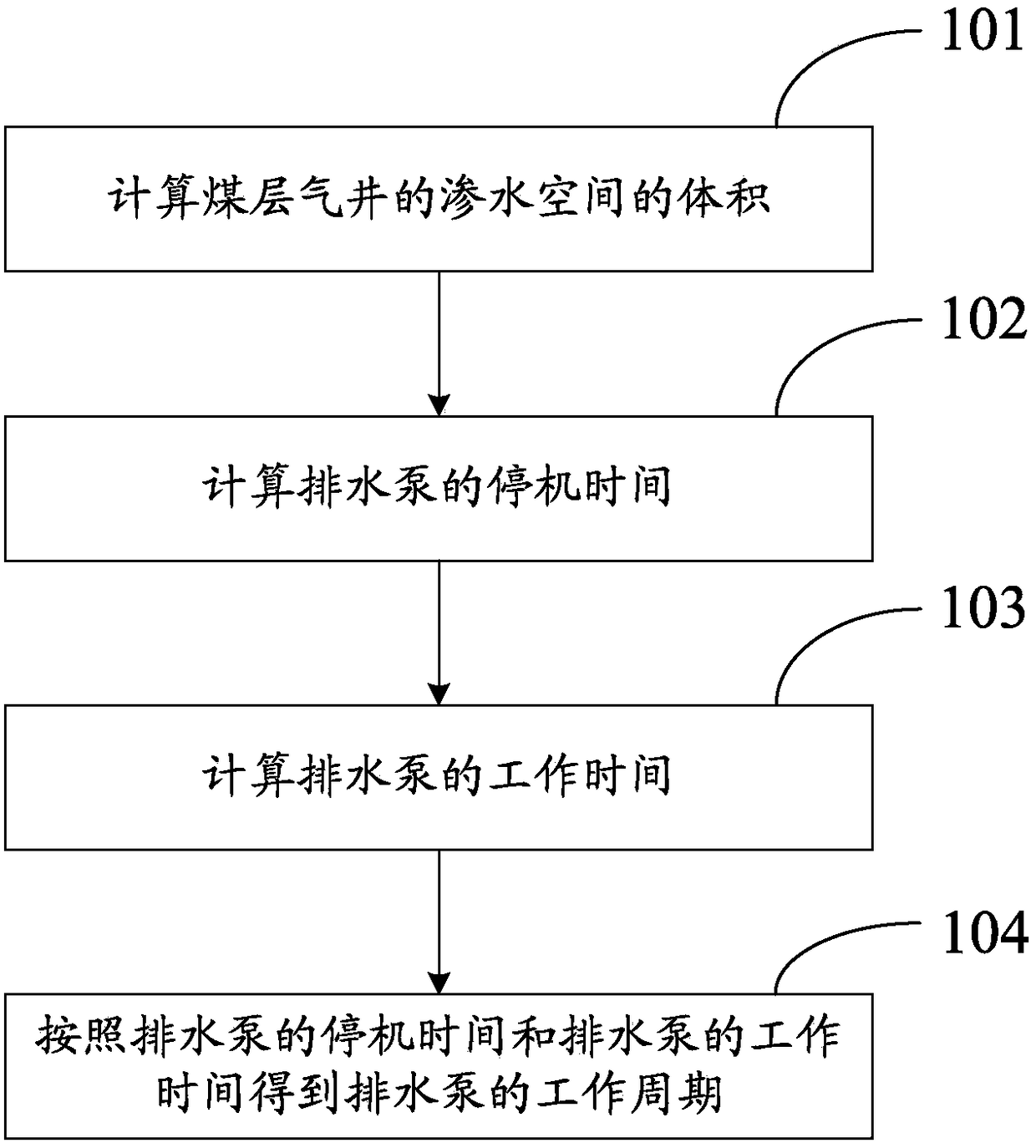

[0040] A method for controlling the working cycle of the drainage pump of a coalbed methane well provided by an embodiment of the present invention, such as figure 1 As shown, the method includes:

[0041] Step 101: Calculate the volume of the seepage space of the coalbed methane well according to the inner diameter of the production casing of the coalbed methane well, the outer diameter of the oil extraction pipe, and the distance from the bottom of the coal seam to the plane where the suction port of the drainage pump is located.

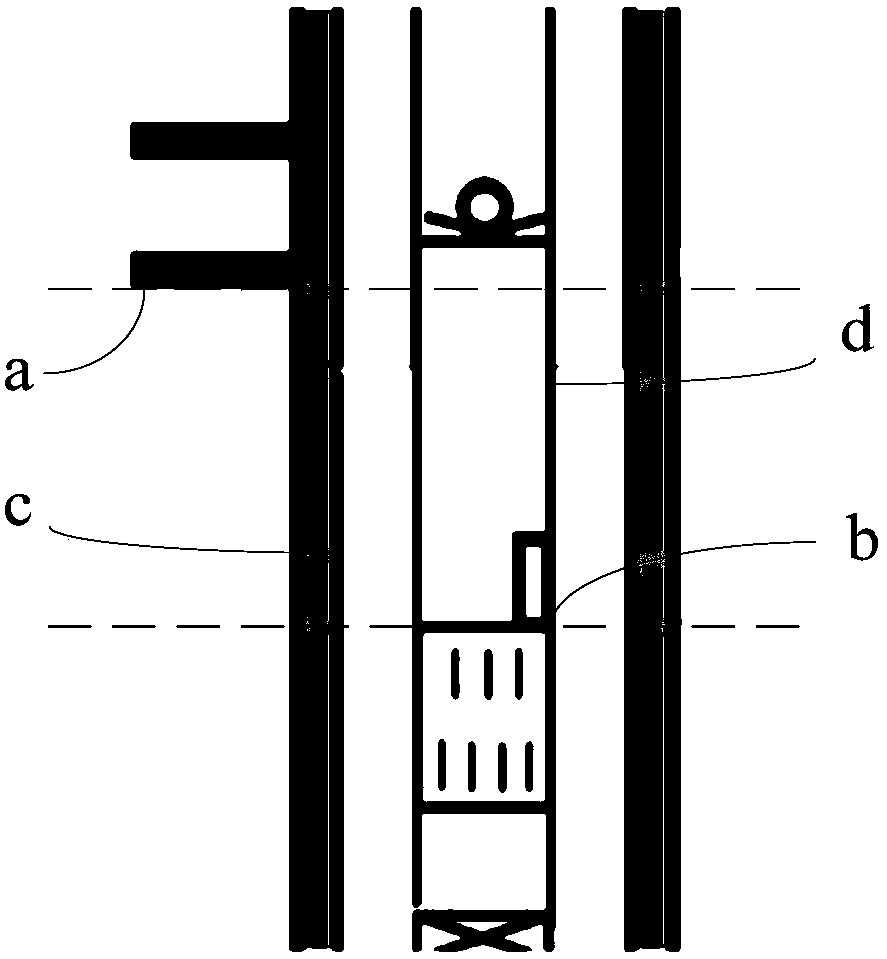

[0042] figure 2 It is a schematic diagram of the structure of a coalbed methane well, combined with figure 2 , the water seepage space is the annular space surrounded by the bottom a of the coal seam, the plane b where the suction inlet of the drainage pump is located, the inner peripheral wall c of the production casing, and the outer peripheral wall d of the oil extraction pipe.

[0043] Step 102: Calculate the downtime of the drainage pump ...

Embodiment 2

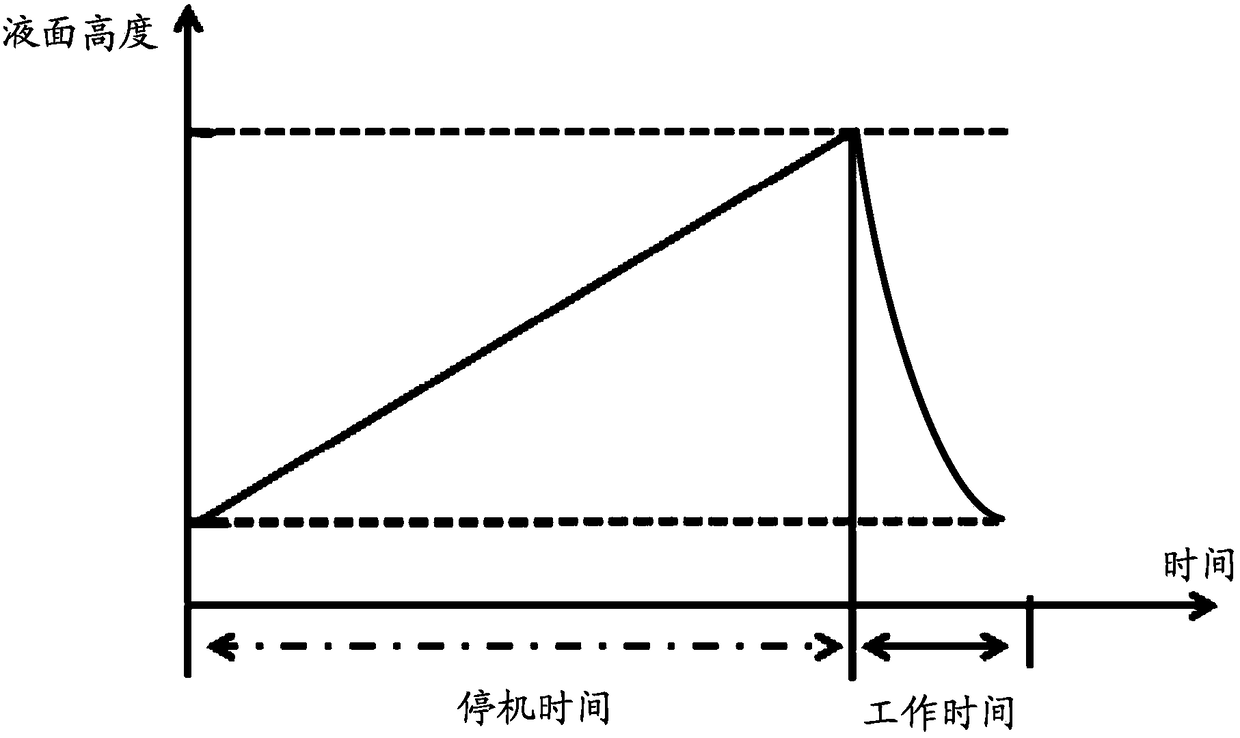

[0048] The embodiment of the present invention provides another method for controlling the working cycle of the drainage pump of a coalbed methane well. This method can be applied to the H2-2 well under the jurisdiction of the Changzhi Coalbed Methane Exploration and Development Branch Company. In order to describe in more detail the present invention provides method, the method will be further explained through the actual specific values below, see Figure 4 , the method includes:

[0049] Step 201: Obtain the inner diameter of the production casing of the coalbed methane well, the outer diameter of the oil extraction pipe, and the distance from the bottom of the coal seam to the plane where the suction port of the drainage pump is located.

[0050] Among them, the distance between the bottom of the coal seam and the plane where the suction port of the drainage pump is located can be the height difference between the plane where the bottom of the coal seam is located and the ...

Embodiment 3

[0069] An embodiment of the present invention provides a device for controlling the working cycle of the drainage pump of a coalbed methane well, the device comprising:

[0070] The calculation unit is used to calculate the volume of the seepage space of the coalbed methane well according to the inner diameter of the production casing of the coalbed methane well, the outer diameter of the oil extraction pipe, and the distance from the bottom of the coal seam to the plane where the suction port of the drainage pump is located. The water seepage space is the bottom of the coal seam, The annular space surrounded by the plane where the suction inlet of the drainage pump is located, the inner peripheral wall of the production casing and the outer peripheral wall of the oil extraction pipe; the downtime of the drainage pump is calculated according to the volume of the seepage space and the water seepage per hour of the coalbed methane well; the downtime of the drainage pump is calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com