Vacuum switch tube and vacuum switch

A vacuum switch tube and end cap technology, which is applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of poor strength of end caps, concave end caps, unbearable problems, etc., and achieve stable structure and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

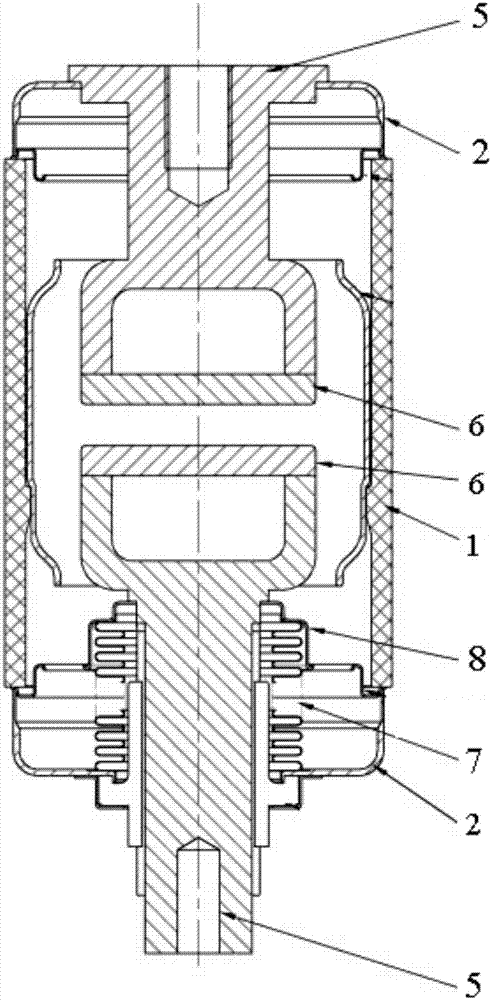

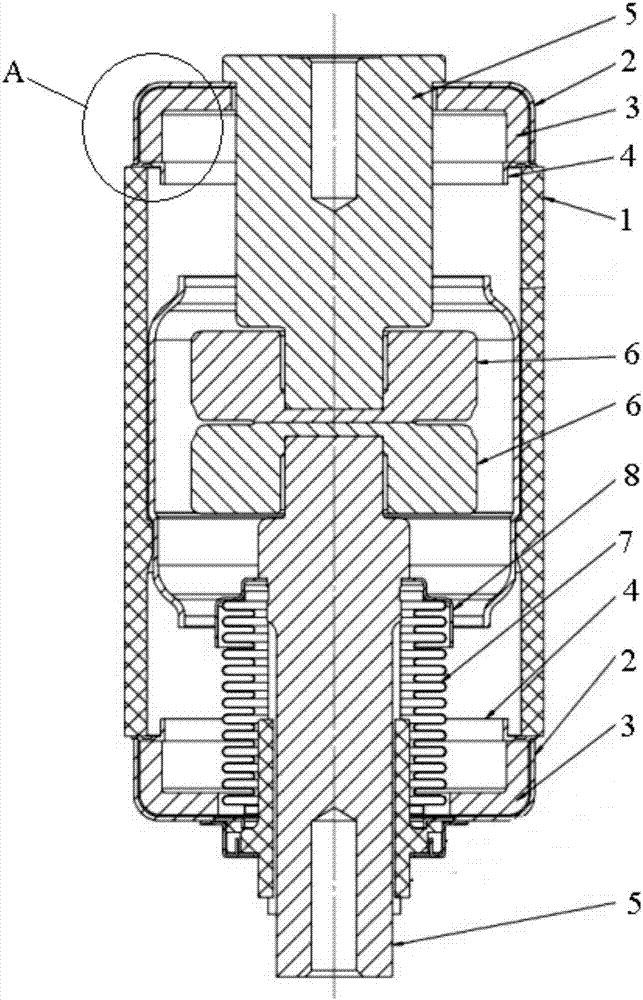

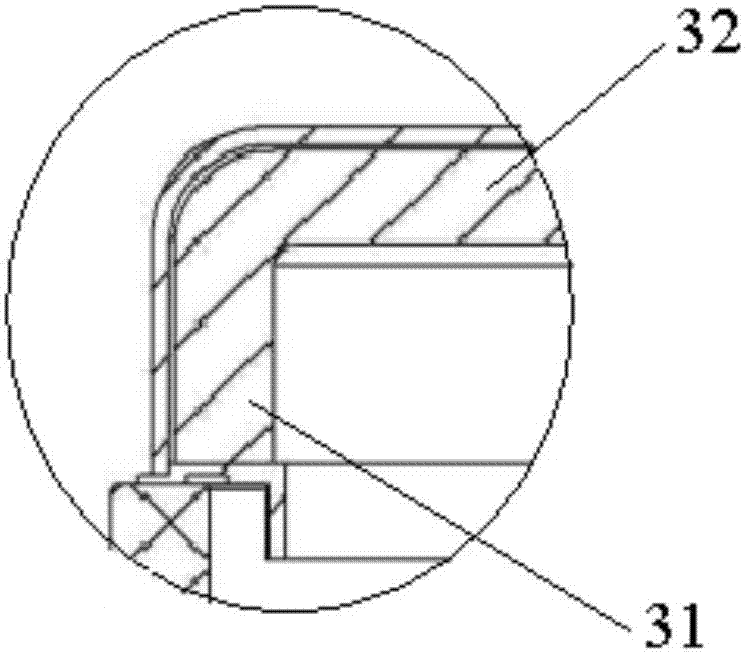

[0030] This preferred embodiment provides a vacuum switch tube, such as figure 2 with image 3 As shown, it includes an insulating shell 1, the two ends of the insulating shell 1 are respectively provided with end caps 2, and the inner sides of the two end caps 2 are provided with a reinforcing structure 3, and the reinforcing structure 3 is used to support the end when making a thermoplastic solid-sealed pole. Cover 2. The reinforcement structure 3 is preferably but not limited to be made of steel, and may also be other materials with appropriate strength.

[0031] The vacuum switch tube provided in this embodiment is provided with a reinforcing structure 3 supporting the end cover 2 when making a thermoplastic solid-sealed pole. When making a thermoplastic solid-sealed pole, the vacuum interrupter must withstand tens of times the atmospheric pressure , the reinforcing structure 3 can avoid the problem of the function loss of the vacuum interrupter caused by the serious co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com