Agricultural machinery material conveying chain

A technology for conveying chains and agricultural machinery, which is applied to conveyors, transportation and packaging, etc., can solve the problems of inconvenient disassembly and replacement, the chain is easy to get stuck, and the use is inconvenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

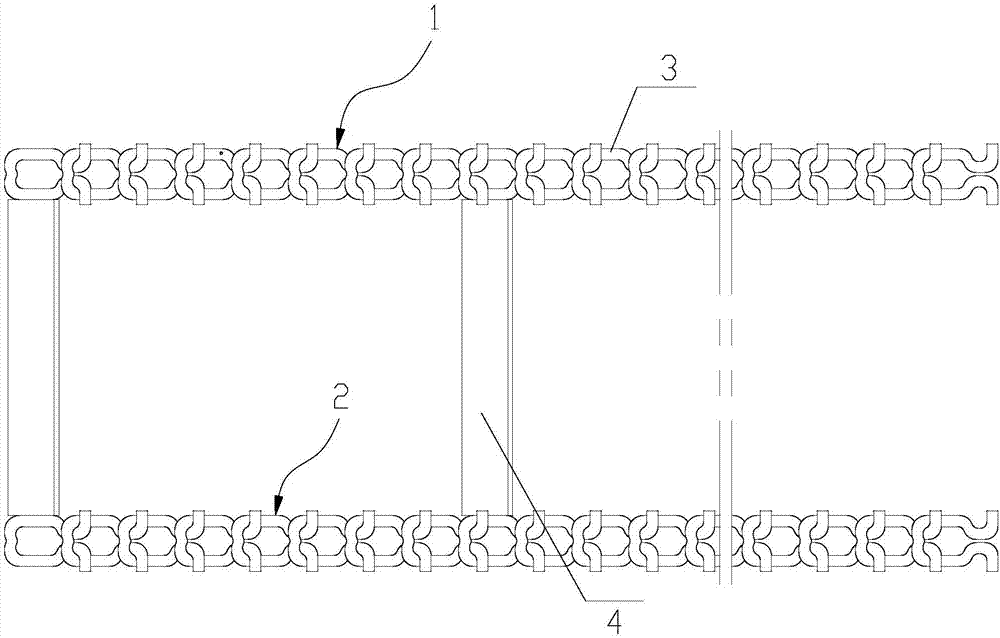

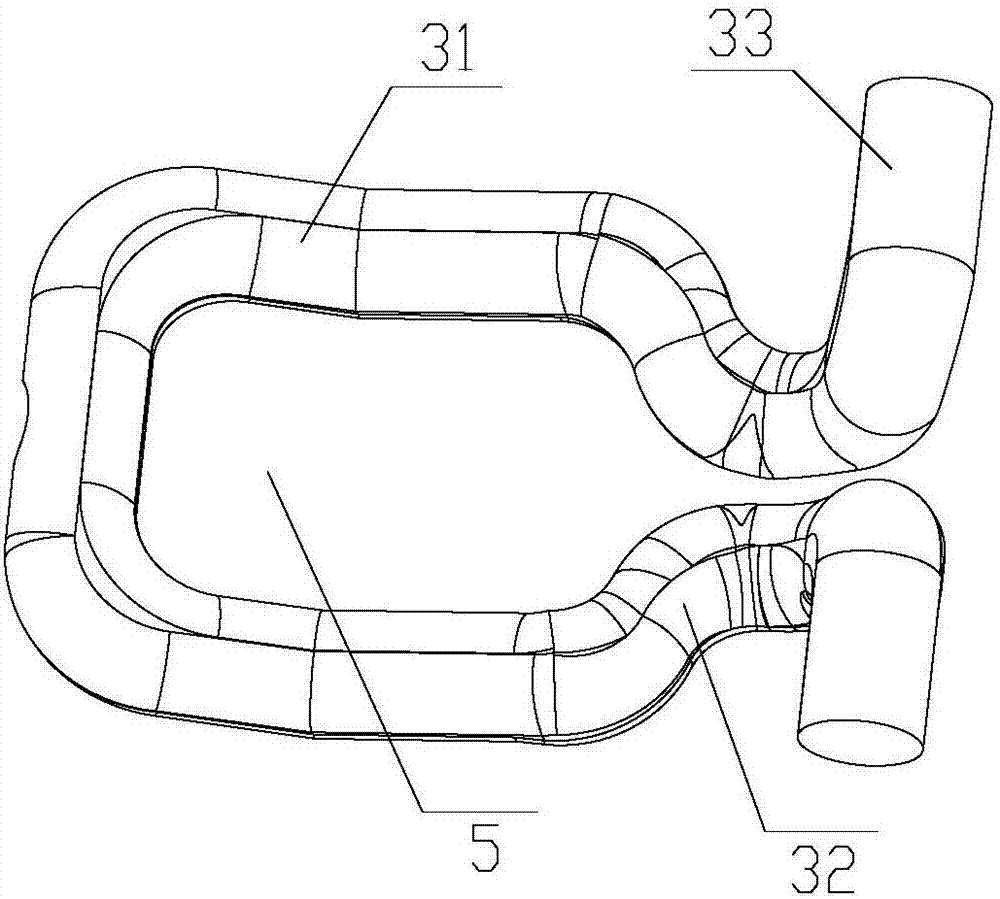

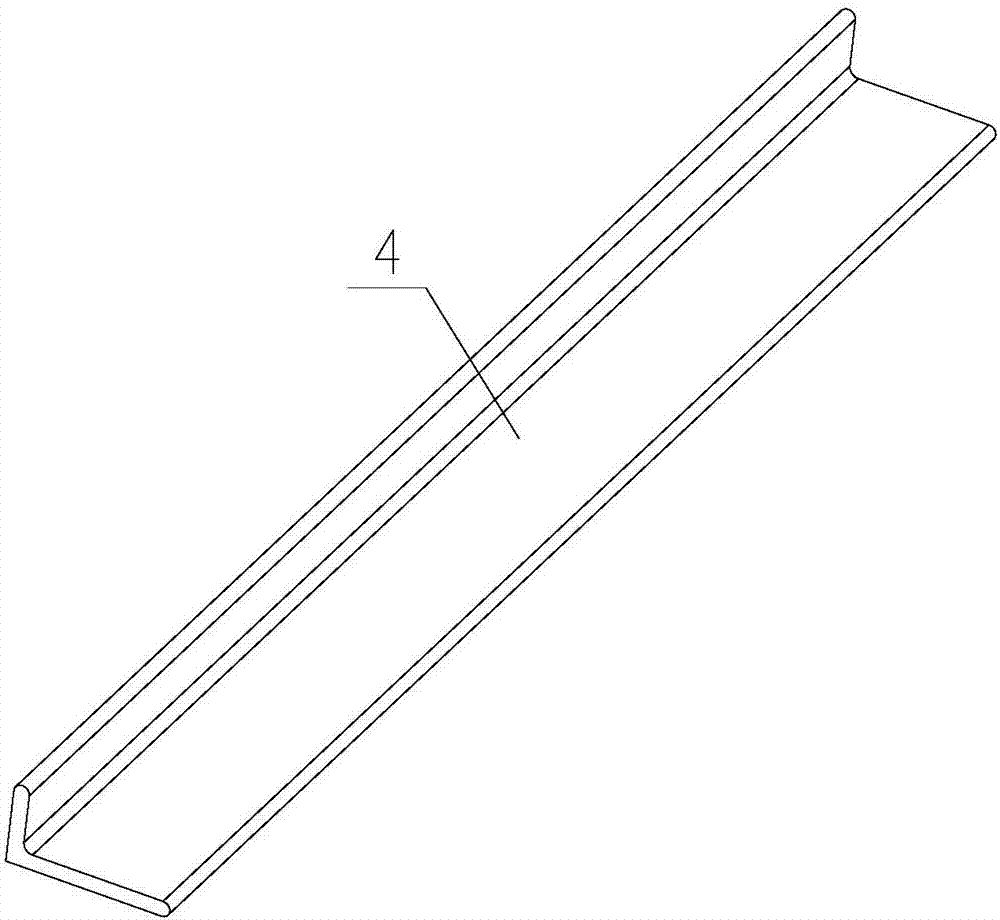

[0016] Such as Figure 1 to Figure 3 As shown, the present invention discloses an agricultural machinery material conveying chain, which includes a left chain 1 and a right chain 2 arranged in parallel, and the left chain 1 and the right chain 2 are connected by several rigid connectors. Wherein, as an improvement of the present invention, the left chain 1 and the right chain 2 are composed of several chain links 3 with the same structure connected end to end in sequence, and the chain links 3 are integrally formed by bending metal bars. Specifically, the chain link 3 includes a buckle section 31 surrounding the buckle hole 5, a shrinkage section 32 that shrinks to both ends of the buckle section 31 in a shrinking shape, and a shrinka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com