Rapid connection leakage repairing device

A kind of leak repair and fast technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of poor leakage treatment effect, difficulty, shortened life and other problems, to achieve pipeline connection and leakage treatment fast and easy to use Long life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

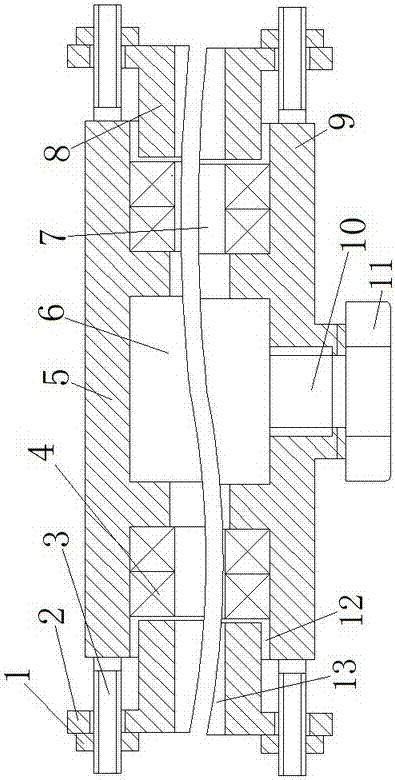

[0007] The outer edge 9 of the tank body 5 of the present invention forms an extrusion cavity 12, and the bolt 3 is fixedly installed on the outer edge 9, and the extrusion sealing ring 4 is placed in the extrusion cavity 12, and the extrusion sealing ring 4 continues An extrusion cover 8 is installed, and the end of the extrusion cover 8 is pushed on the extrusion sealing ring 4. There is an extrusion force arm 2 on the extrusion cover 8, and a through hole is opened on the extrusion force arm 2. The bolt 3 Through the through hole and fastened by the nut 1; the side wall of the tank body 5 has a pressure discharge port 10 communicating with the tank inner cavity 6, and the pressure discharge port 10 is covered with a pressure discharge cock 11 through a screw thread.

[0008] The tank body 5 of the present invention has a tank inner cavity 6, an extrusion sealing ring 4 is an extrusion cavity 7 in the middle, and an extrusion cover 8 has a through cavity 13, and the tank inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com