Sliding top pressure type electronic heat dissipation device

A heat-dissipating device and electronic technology, which is applied in the direction of modification, cooling/ventilation/heating transformation through conduction heat transfer, etc., can solve the problems of overall scrapping, deformation of heat-dissipating device, low heat-dissipating efficiency, etc., and achieve fast installation, rapid heat dissipation, and use Flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

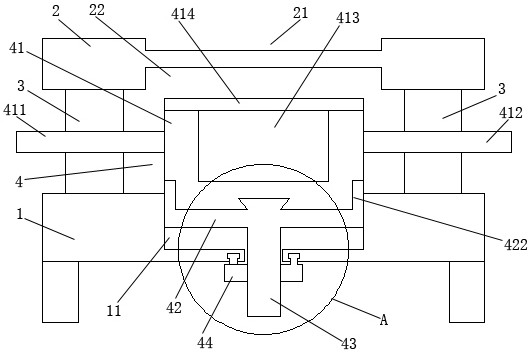

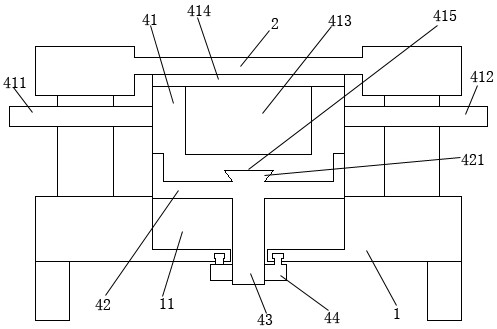

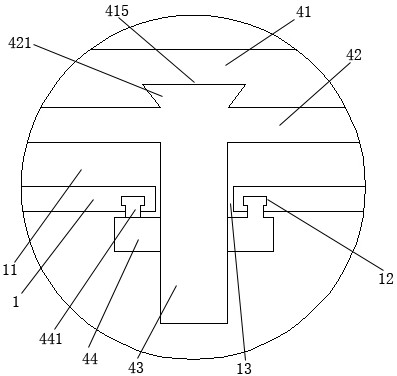

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figures 1 to 4 As shown, a sliding top-pressure electronic cooling device includes an upper mounting plate 2, a connecting plate 3, a lower support seat 1, and a heat dissipation mechanism 4; the upper mounting plate 2 and the lower support seat 1 are arranged in parallel up and down; A sliding gap 5 is provided between the upper mounting plate 2 and the lower support base 1; a plurality of heat dissipation areas 21 are provided on the upper end of the upper mounting plate 2; The connecting plate 3; the middle of the upper end of the lower support seat 1 is provided with a floating groove 11 of a strip structure; the middle of the lower end of the floating groove 11 is provided with a connecting hole 13; the heat dissipation mechanism 4 includes a floating frame 42 , a floating threaded post 43, a drive nut 44, and a cooling bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com