Rigid tube connecting piece with end provided with convex ring

A technology of connecting parts and convex rings, which is applied in mechanical equipment, metal processing equipment, metal processing and other directions, can solve the problems of low efficiency of pipe connection and disassembly, and achieve the effects of reliable fixing, simple operation and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

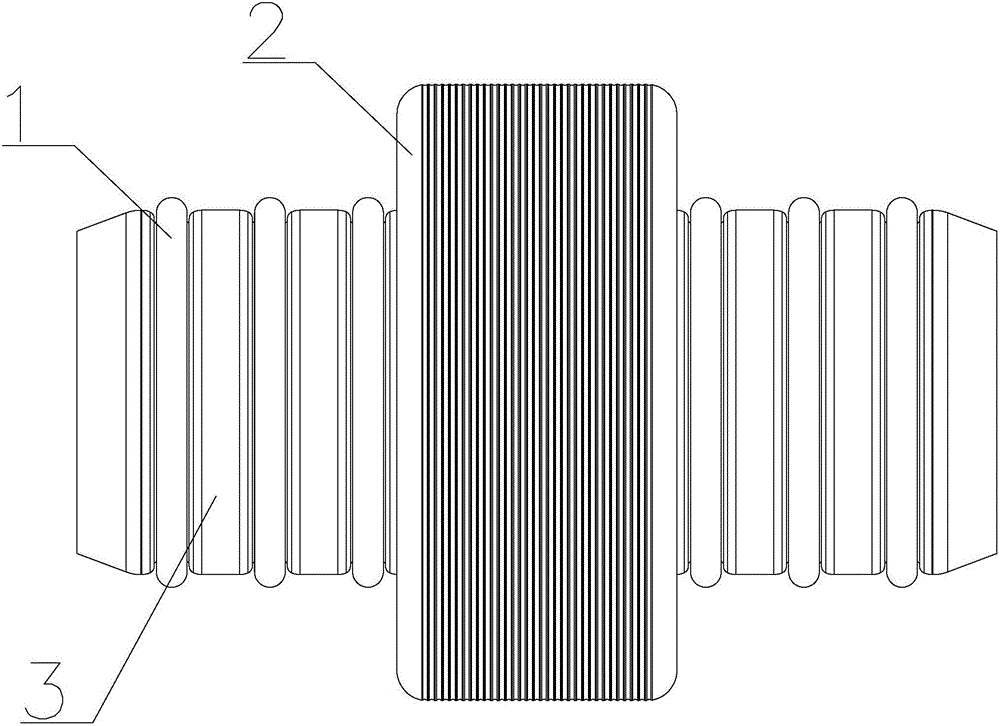

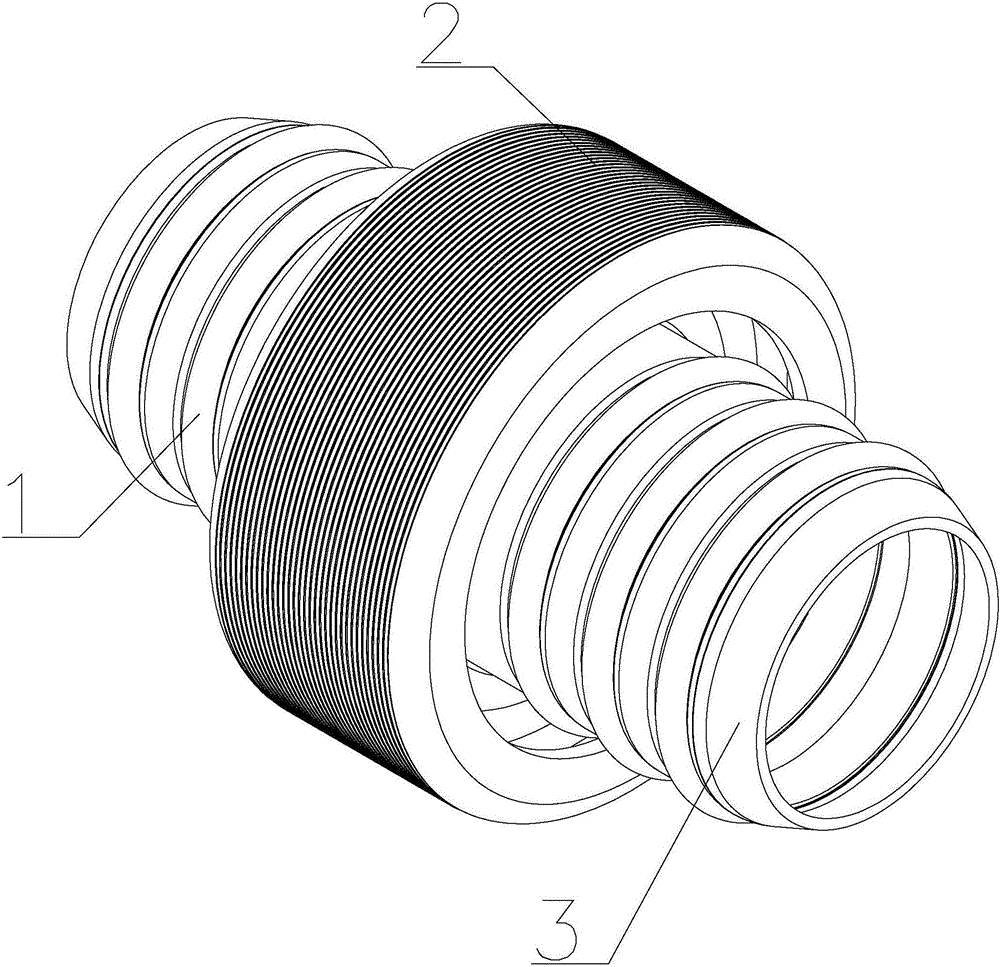

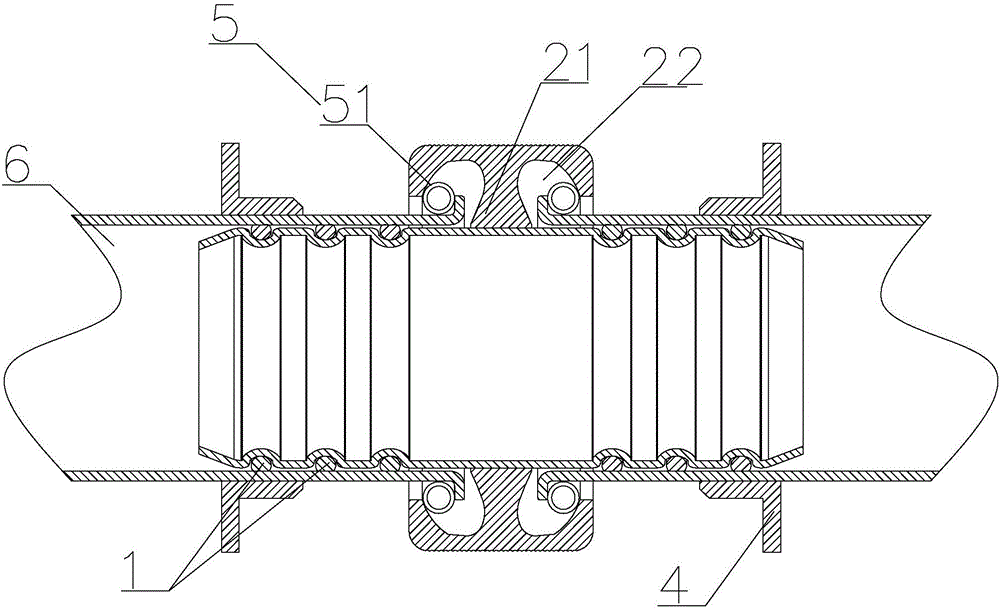

[0030] Example one, refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 with Figure 7 , A hard pipe connector with a convex ring at the end of the present invention, comprising a sealing ring 1 and an inner connecting pipe 3. The hard pipe 6 with a convex ring at the end is sleeved at both ends of the inner connecting pipe 3. At least one sealing ring 1 is provided between the hard tube 6 with a convex ring at one end of the tube 3 and the inner connecting tube 3, and also includes a fixing sleeve 2 and an anti-falling elastic ring 5. The inner connecting tube 3 has two A fixing sleeve 2 is sleeved between the hard pipes 6 with convex rings at the ends. The anti-falling elastic ring 5 is arranged in the fixing grooves 22 provided on the inner sides of the two ends of the fixing sleeve 2, and the fixing grooves 22 are arranged The inner boss 21 is fixed, the anti-dropping elastic ring 5 is sleeved on the hard tube 6 with a convex ring at the end located in the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com