Rotary RO (Reverse Osmosis) membrane filtration assembly

A membrane filtration and rotary technology, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve the problems of inconvenient maintenance, large space occupation, poor sealing performance, etc., and achieve quick disassembly and assembly, excellent sealing performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

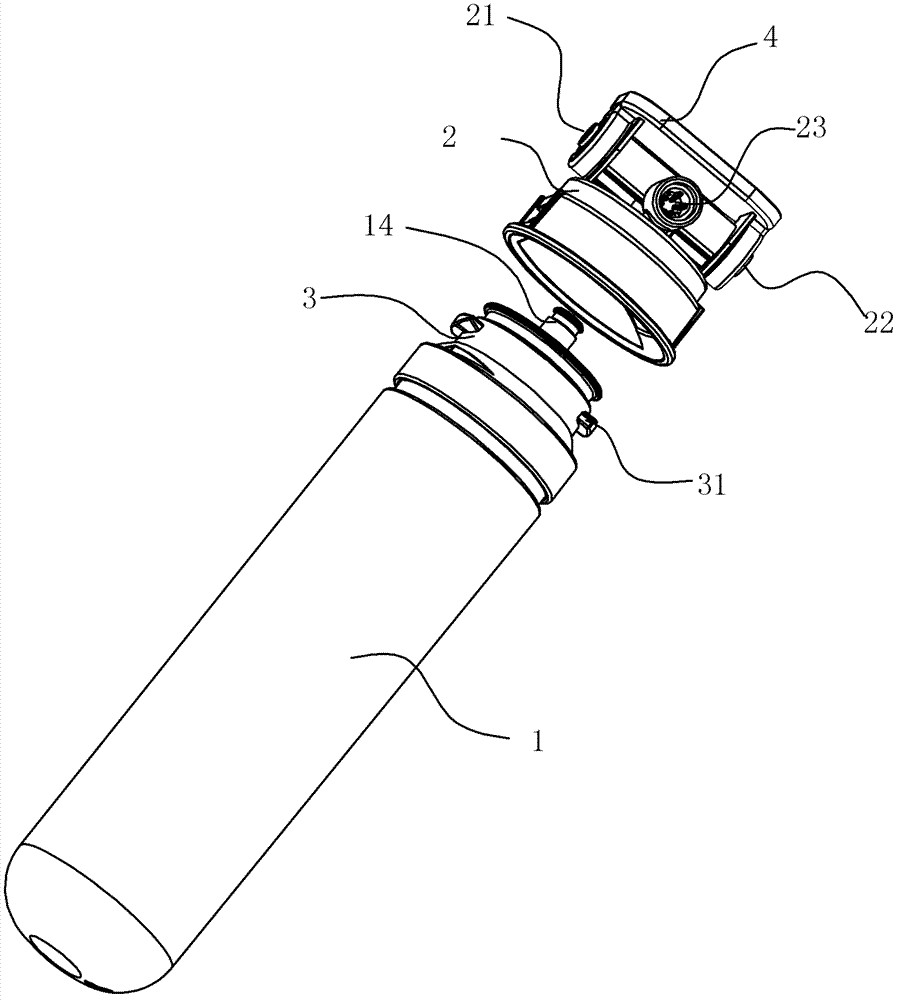

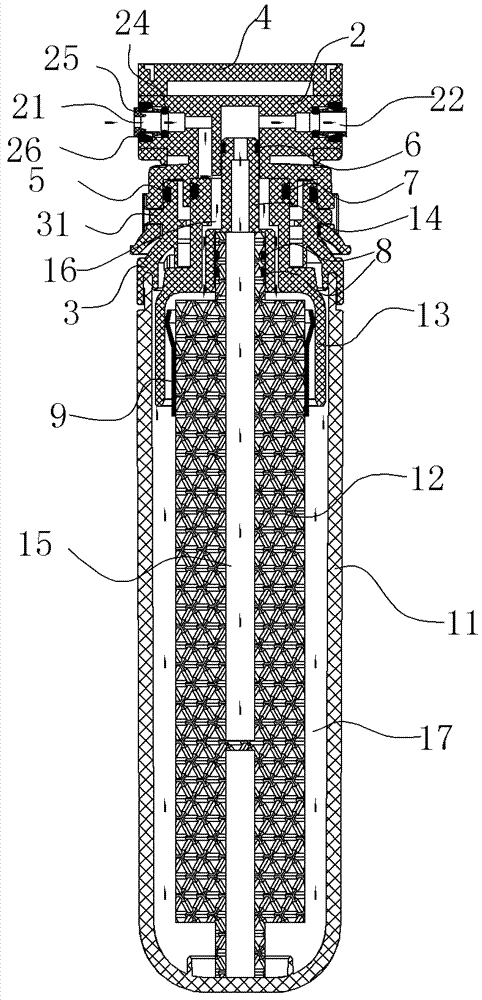

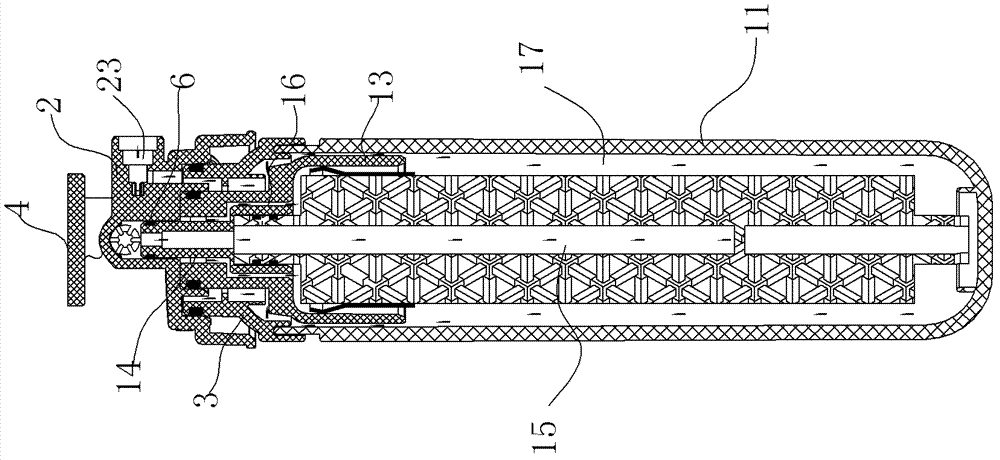

[0019] As shown in the figure, a rotary RO membrane filter assembly includes a filter element assembly 1 provided with an RO membrane, a filter base 2 and a filter cover 3, and the filter element assembly 1 includes a cylindrical filter shell 11 and a filter element disposed in the filter shell 11. The RO membrane filter element 12, the filter seat 2 is provided with a source water inlet 21, a pure water outlet 22 and a concentrated water outlet 23 that communicate with the filter element assembly 1, and the lower two sides of the filter seat 2 are provided with clamping grooves; filter cover; 3. The spin-melting sleeve is placed on the upper end of the filter shell 11 of the filter element assembly 1, and its left and right ends are provided with lugs 31 that cooperate with the card grooves of the filter seat 2. The groove is clamped, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com