Power-split hybrid power system mode switching method

A hybrid power system and hybrid mode technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, power units, and general power units, etc. End-to-end synthetic torque fluctuation, transmission component impact, etc., to achieve the effect of taking into account the mode switching time and energy consumption, and improving driving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

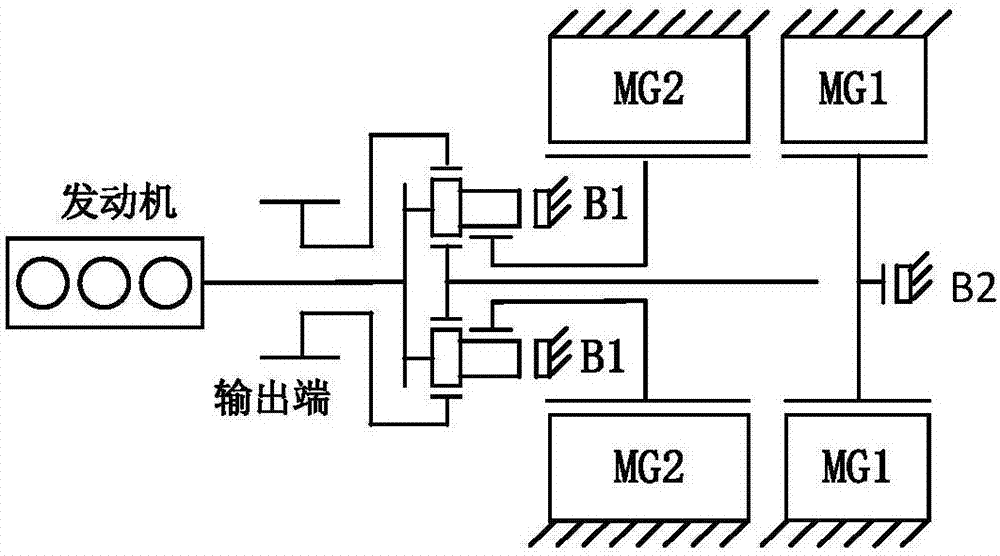

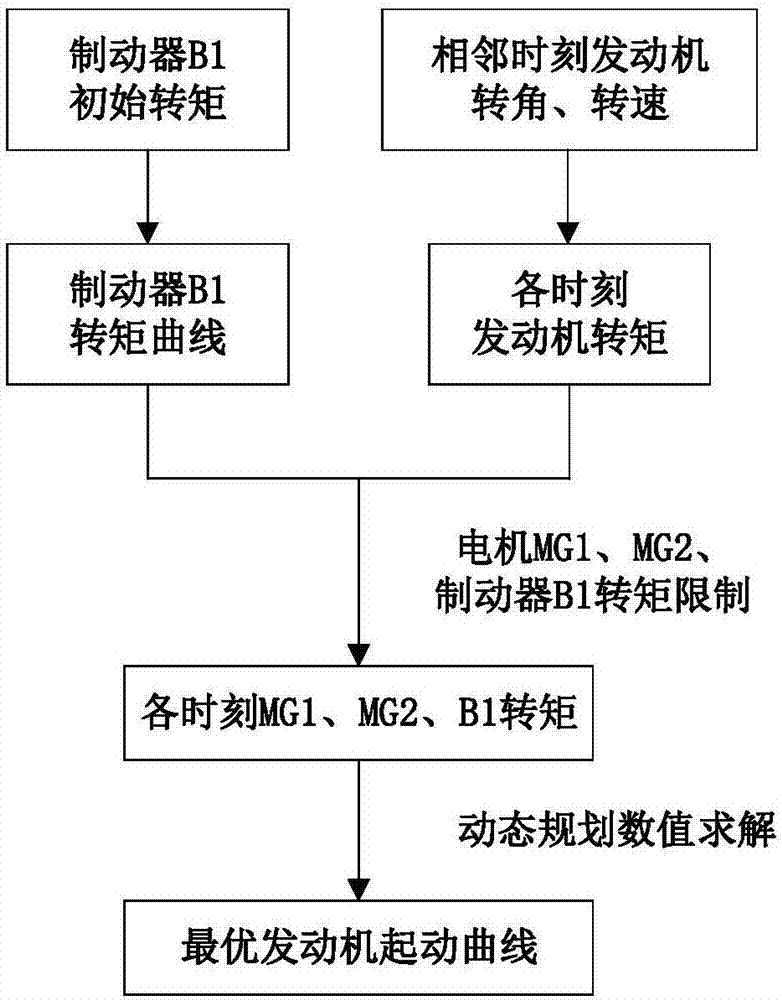

[0024] The present invention provides an optimal coordination control method based on the switching process of pure electric to hybrid power mode of power split hybrid power system. As a preferred embodiment of the present invention, power split hybrid power system such as figure 1 As shown, the hybrid power system consists of an engine, motors MG1, MG2, brakes B1, B2 and a planetary row structure power coupling device. The hybrid power system based on this type can realize multiple working modes such as pure electric power, hybrid power, driving charging and regenerative braking.

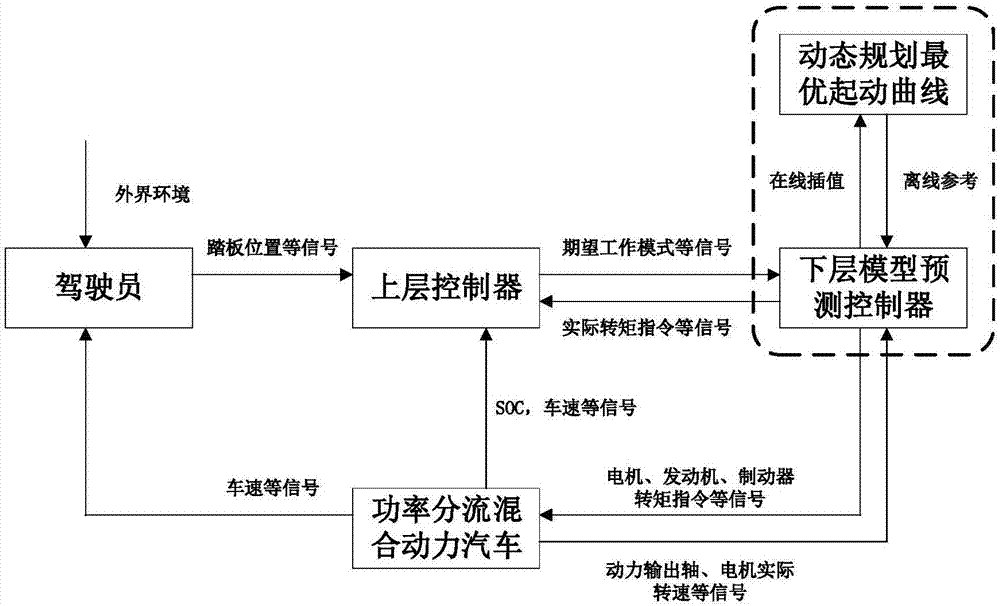

[0025] The vehicle control framework of the power split hybrid electric vehicle involved in the present invention is as follows: figure 2 shown. The pure electric to hybrid mode switching process specifically includes three stages: pure electric mode, engine starting process and hybrid mode. Specifically, when driving in pure electric mode, the whole vehicle is driven solely by the motor MG2 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com