Float production storage and offloading (FPSO) crane cylinder body and construction and installation method thereof

An installation method and crane technology, applied to cranes and other directions, can solve the problems of occupying a large hull space and achieve the effects of ensuring structural strength, saving hull space, and reducing construction difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

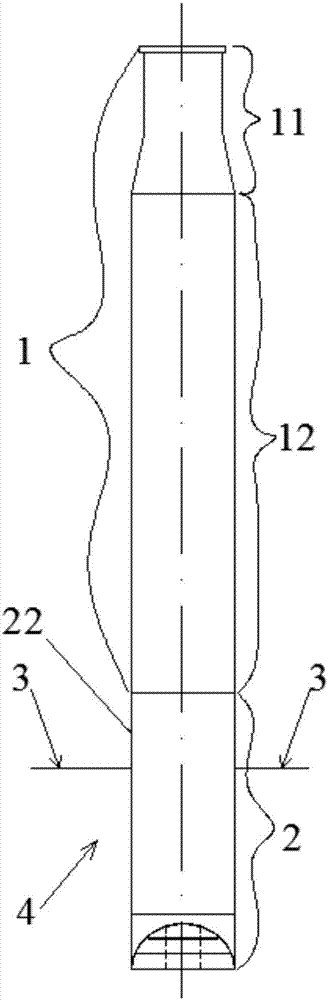

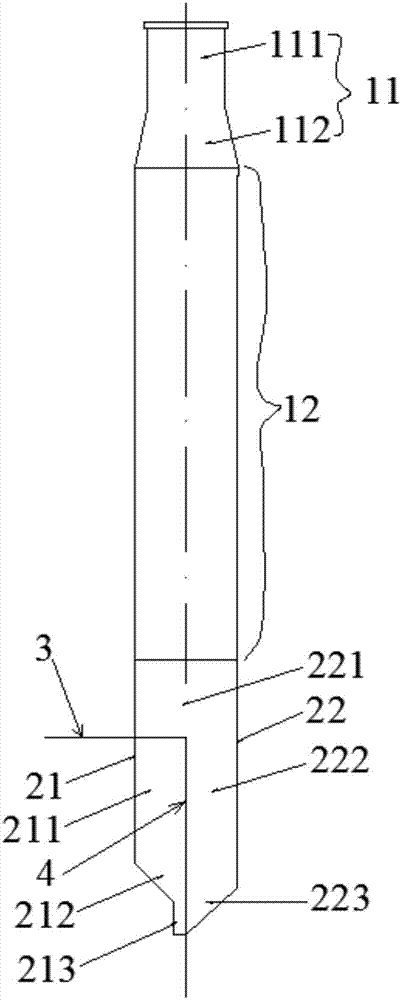

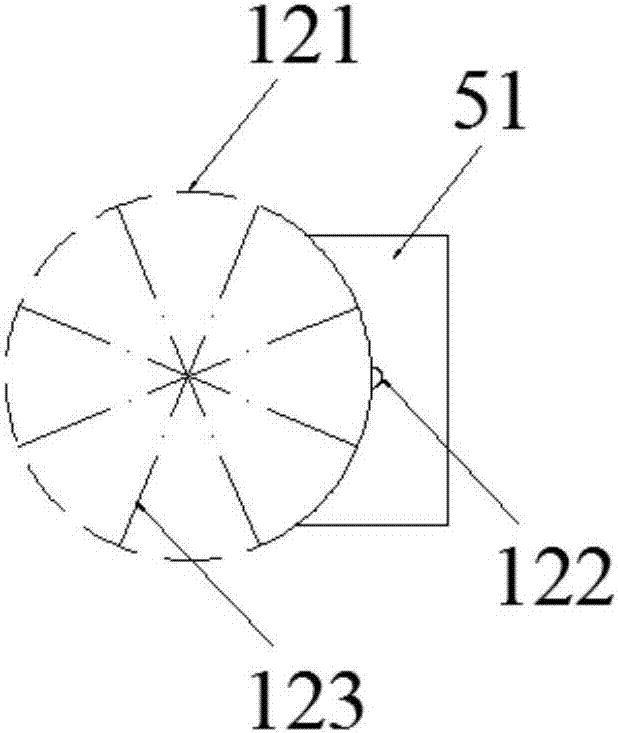

[0050] Such as Figure 1~2 , the FPSO gram suspension cylinder body, including the upper cylinder body 1 and the lower cylinder body 2 connected in sequence: the upper cylinder body 1 is formed by sequentially connecting the A part 11 and the B part 12, and the A part 11 is formed by the first cylinder body 111 and the first cylinder body 111 The first frustum-shaped cylinder 112 is connected up and down, and the B part 12 is cylindrical, which is the second cylinder; the lower cylinder body 2 includes an inboard part 21 and an outboard part 22, and the inboard part 21 includes an up and down connection in turn. The first semi-cylindrical body 211, the first semi-circular truncated cylindrical body 212 and the second semi-cylindrical body 213, the outboard part 22 includes the third cylindrical body 221, the third semi-cylindrical body 222 and the first semi-conical body connected up and down in sequence. shaped cylinder 223, the upper cylinder body 1 is connected with the out...

Embodiment 2

[0053] The construction and installation method of the FPSO crane body of embodiment 1 are as follows:

[0054] S1: The construction method of the FPSO crane body:

[0055] S11: Manufacture of lower hull inboard part 21, lower hull outboard part 22, upper hull A part 11, upper hull B part 12:

[0056] (1) Steel plate blanking cutting: cutting different steel plate raw materials according to the different shapes of the lower shell inboard part 21, the lower shell outboard part 22, the upper shell A part 11, and the upper shell B part 12;

[0057] (2) Steel plate rolling processing and forming: the inboard part 21 of the lower cylinder body is divided into the first semi-cylindrical body segment, the first semi-circular frustum-shaped cylindrical body segment and the second semi-cylindrical body segment, respectively rolled and processed, and the lower cylinder body The outboard part 22 of the body is divided into the third cylindrical body segment, the third semi-cylindrical b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com